RE: V6 on Mini: Heat Creep?

@karl-herbert

It works as is for me.

--------------------

Chuck H

3D Printer Review Blog

extruder

@cwbullet

I can only say that my E3D V6 hotend (original by E3D) runs perfectly on the Mini. I didn't have to change the temperature settings in the firmware. The PTFE (capricorn) is one piece - from the extruder to the hotend and of course cleanly chamfered with my special tool:

https://www.prusaprinters.org/prints/34035-ptfe-multitool

I also have to mention that I never used the original Mini Extruder and immediately installed something reliable. It has power without end - no jams and no notched filaments. Even carbon containing materials can be printed perfectly.

E3D is the way to go on the Mini

I took a hybrid approach. I bought the metal-only kit from E3D direct, and recycled the mini heatblock, thermistor, fan, and heater cartridge. No changes to the firmware were required.

The mount was a pull off of prusaprinters.org: 31006-prusa-mini-v6-hotend-adapter

I modified it to remove the strain relief, and designed a spacer and chain mount for my x-chains.

I just went 100/100 successful prints on 16 machines over 7 days time using PLA and PETG. This was a test to isolate the random serial disconnect bug I've been encountering over the months, which was successful.

RE: E3D is the way to go on the Mini

👍 some pictures would be nice 🙂

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

heat issues

I took a hybrid approach. I bought the metal-only kit from E3D direct, and recycled the mini heatblock, thermistor, fan, and heater cartridge. No changes to the firmware were required.

The mount was a pull off of prusaprinters.org: 31006-prusa-mini-v6-hotend-adapter

I modified it to remove the strain relief, and designed a spacer and chain mount for my x-chains.

I just went 100/100 successful prints on 16 machines over 7 days time using PLA and PETG. This was a test to isolate the random serial disconnect bug I've been encountering over the months, which was successful.

How did your stock fan cope with the increase of temps and demand to cool the heatsink,

reading through some threads I've heard the fan runs at 38% default and without 3rd party firmware you're unable to increase this.

RE: E3D with Sherpa mini orbiter

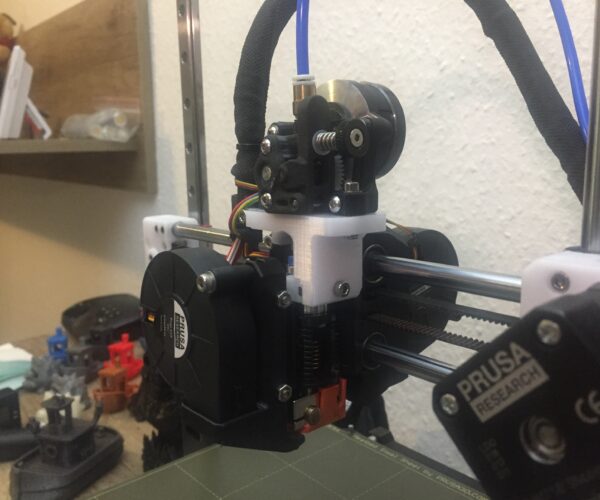

I wanted to get in touch again and am now satisfied with the E3D + bracket from karl-herbert and with the Sherpa mini orbiter, because I wanted to get away from bowden and so far every pressure has been reliable, even at 100mm/s.

Thanks again to Karl, without the files that were made available it would not have been possible.

Fan

I took a hybrid approach. I bought the metal-only kit from E3D direct, and recycled the mini heatblock, thermistor, fan, and heater cartridge. No changes to the firmware were required.

The mount was a pull off of prusaprinters.org: 31006-prusa-mini-v6-hotend-adapter

I modified it to remove the strain relief, and designed a spacer and chain mount for my x-chains.

I just went 100/100 successful prints on 16 machines over 7 days time using PLA and PETG. This was a test to isolate the random serial disconnect bug I've been encountering over the months, which was successful.

How did your stock fan cope with the increase of temps and demand to cool the heatsink,

reading through some threads I've heard the fan runs at 38% default and without 3rd party firmware you're unable to increase this.

My stock fan with a similar set up is more than adequate.

--------------------

Chuck H

3D Printer Review Blog

RE: E3D with Sherpa mini orbiter

Interesting design - many paths lead to the goal - well done 👍

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

Sherpa

The Sherpa is a unique design for sure.

--------------------

Chuck H

3D Printer Review Blog

Prusa mini Sherpa extruder

Not really, just changed it accordingly for my E3D, the only thing that is unique is my LinearMod on the left side, so that the arm runs more stable.

https://www.prusaprinters.org/prints/66519-prusa-mini-sherpa-extruder-direct-drive-conversion

RE: Fan setting and extruder

I took a hybrid approach. I bought the metal-only kit from E3D direct, and recycled the mini heatblock, thermistor, fan, and heater cartridge. No changes to the firmware were required.

The mount was a pull off of prusaprinters.org: 31006-prusa-mini-v6-hotend-adapter

I modified it to remove the strain relief, and designed a spacer and chain mount for my x-chains.

I just went 100/100 successful prints on 16 machines over 7 days time using PLA and PETG. This was a test to isolate the random serial disconnect bug I've been encountering over the months, which was successful.

How did your stock fan cope with the increase of temps and demand to cool the heatsink,

reading through some threads I've heard the fan runs at 38% default and without 3rd party firmware you're unable to increase this.

I cannot confirm this issue exists. Stock fan/settings with referenced mount and no heat creep observed in 500+ prints since the mod crusade. All 36 minis in my army have this same config, if there are issues, I'd look to the extruder.

Along those lines, I'm using a MK3S+ (R6) extruder ported over to the mini.

I shared the R4 design (which has the chain and spacer mount) on prusaprinters.org: 56487-mk3s-extruder-for-prusa-mini

I've found the bondtech gears and integrated filament runout sensor to be extremely reliable, and this setup has put my mini rack's reliability on par with the MK3S+.

Enjoy!

thanks for sharing

I took a hybrid approach. I bought the metal-only kit from E3D direct, and recycled the mini heatblock, thermistor, fan, and heater cartridge. No changes to the firmware were required.

The mount was a pull off of prusaprinters.org: 31006-prusa-mini-v6-hotend-adapter

I modified it to remove the strain relief, and designed a spacer and chain mount for my x-chains.

I just went 100/100 successful prints on 16 machines over 7 days time using PLA and PETG. This was a test to isolate the random serial disconnect bug I've been encountering over the months, which was successful.

How did your stock fan cope with the increase of temps and demand to cool the heatsink,

reading through some threads I've heard the fan runs at 38% default and without 3rd party firmware you're unable to increase this.

I cannot confirm this issue exists. Stock fan/settings with referenced mount and no heat creep observed in 500+ prints since the mod crusade. All 36 minis in my army have this same config, if there are issues, I'd look to the extruder.

Along those lines, I'm using a MK3S+ (R6) extruder ported over to the mini.

I shared the R4 design (which has the chain and spacer mount) on prusaprinters.org: 56487-mk3s-extruder-for-prusa-mini

I've found the bondtech gears and integrated filament runout sensor to be extremely reliable, and this setup has put my mini rack's reliability on par with the MK3S+.

Enjoy!

Good to hear about not having to mess around with the fans and that extruder is just like my mk3s+ reliability then its a must print.

looks like I just need to source the gears and sensor over here in the UK,thanks once again for responding and sharing your designs.

extruder magnet force ?

I also have to mention that I never used the original Mini Extruder and immediately installed something reliable. It has power without end - no jams and no notched filaments. Even carbon containing materials can be printed perfectly.

Hey Karl can I ask what Force/Pull one of these magnets produce please ?

interesting to see how it works and without having to much force it crushes the filament or not enough force to pull against the filament.

Thank you

RE: extruder magnet force ?

Berni has given a short description here:

https://www.bernis-simple-bowden-extruder.com/parts/magnete/199/magnete-fuer-magnetic-extruder?c=27

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.