RE: PC4 M8x1.25 Bowden Pneumatic Connectors

Yes, your photos triggered my question 😊 but my brass ones came without a clip. From your answer I assume that it best to invest some time in figuring out which size I should order 👍🏻

Mini with FW:4.4.1 + SuperPINDA + Bondtech Heatbreak + PC4-M8 couplers + 1 piece boden

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

You coold even print them. search for “Bowden Collet Clip” on Thingiverse and similar. They reduce the play by restraining ring movement...

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@3dprintedgr

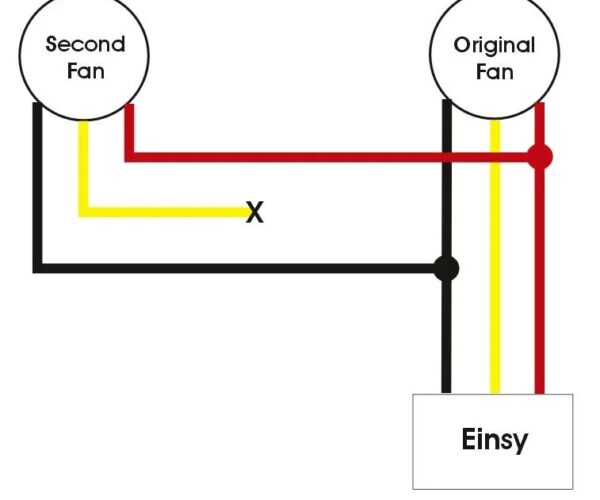

Parallel to the other with only one PWM signal (yellow) to the original fan:

here is everything illustrated:

https://www.prusaprinters.org/prints/42554-original-prusa-mini-e3d-v6-hotend

Wouldn't good ole' fan splitter used in PCs work? They come in 3-pin voltage regulated and 4-pin PWM variety. I have bag full of them, they come with every Noctua fan or CPU cooler. Sensing wire is connected to one branch only, understandably.

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@crawlerin

With me it works fine this way, but you can of course try other solutions. But I would be interested to know how you solved it. As I only use Noctua fans, I already have a shoebox full of small parts.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@oxygen

look here:

https://www.thingiverse.com/thing:3499966

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@karl-herbert

I primted 100 satrurday. Great test print.

--------------------

Chuck H

3D Printer Review Blog

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@karl-herbert

of course, I can print them 🙂 still after 2 years of having a 3D printer I still fall in the "I have to buy this trap" -- Danke!

Mini with FW:4.4.1 + SuperPINDA + Bondtech Heatbreak + PC4-M8 couplers + 1 piece boden

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@crawlerin

Its the same thing i guess. Just the split looks better aesthetically.

@karl-herbert

Thanks for that link Karl, somehow I only come across the useless stuff on prusaprinters.org and I am missing the interesting ones 😀

The assembly looks very reliable. I still don't understand why Prusa went for a new design instead of using the same old trusted one.

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

I dont understand why Prusa decided to not use these types of connectors... I am now having to wait ages for delivery of PC4-M8 type... For some reason, I have now gone through 3 of the prusa type connectors as the brass fitting is blowing off the tubing mid print.

My Mini has: A SuperPINDA + Bondtech Heatbreak + Bondtech Extruder installed

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@steve-smith

I ordered some also.

--------------------

Chuck H

3D Printer Review Blog

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@steve-smith

I agree with you... seems that I have became one of the "evangelists" of the Pneumatic Connectors. There are some people defending tooth and nail the Compression Fittings, but I don't see any advantages on using them... PTFE tube can be damaged by PC teeth? I don't mind if I have to change it every few months (it's is only 30cm long). Moreover, if you use a collet below the PC release ring, the PTFE tube does not move at all during retractions, and the possible damage should be much lower.

An even worse thing is the Compression Fitting not being Pass-Through and obliging you to split the Bowden tube into 3 separate pieces that at the end is the cause of clogging problems when with time, heat and compression, the small piece inside the heatbreak shrinks a bit.

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

[...]

An even worse thing is the Compression Fitting not being Pass-Through and obliging you to split the Bowden tube into 3 separate pieces that at the end is the cause of clogging problems when with time, heat and compression, the small piece inside the heatbreak shrinks a bit.

That is also what I did; 1 piece boden from extruder to heat-break and I am loving it. The only upgrade still waiting is replacing the standard boden with a capricorn-XS tube (tube is in order)

Mini with FW:4.4.1 + SuperPINDA + Bondtech Heatbreak + PC4-M8 couplers + 1 piece boden

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@oxygen

The PC4 fittings have proven themselves very well on the MK3 and they do exactly the same on the Mini. One continuous PTFE - no more clogging and no more out popping PTFE tubes.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@karl-herbert

Exactly as I have always thought... I have owned FOUR bowden type printers and never had an issue with PC couplings. For me, the three pieces bowden tube is an engineering ABERRATION...But there seems to be a lot of people, specially in the Facebook group, defending Prusa choice in this matter, even praising it as "elegant"...

At least, they could have drilled the compresion fittings with a 4.1mm bore to make them pass-through, instead of having the infamous 2.2mm ID throat that forces to split the bowden tube in three.

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@ignacmc

In addition, overtightening the nuts of the brass compression fittings also compresses the PTFE and thus reduces the inner diameter. -> more friction...

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@karl-herbert

- Yes, and during olives installation you need to temporarily introduce something rigid inside the tube to avoid crushing it...they recommend a 2mm drill bit, but for a Capricorn XS you are going to need a 1.9mm diameter one...Not easy to find...so problems, problems and more problems!

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@ignacmc

I have tested all this, also with a 1.9mm drill bit, which are relatively easily available in our country, but still the PTFE slipped out of the original fitting every time I printed e.g. XT-CF20.

The only disadvantage of the PC4-M8x1.25 fittings is the somewhat difficult to find (except Aliexpress and ebay) procurement. Alternatively, you can of course print an adapter, which in my view is only an interim solution.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

@karl-herbert

Yes. I believe that this happens to all that use Bondtech extruder...quite happy with PC4 M8x1.25...checking it there is any tube movement every time I print, but happy so far

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

I've made something that may interest you guys

https://www.prusaprinters.org/prints/50703-pc4-m8-x-125-pneumatic-ptfe-conenctor-for-prusa-mi

I ordered the same m8*1.25 connectors but I hate waiting 4 weeks for it to arrive, so I made 3d printed version . So far it holds firmly on the BMG extruder , and I didn't saw any thread degradation. Hotend works too but is more tricky, I rather use classic pneumatic connector or the metal from aliexpress.

RE: PC4 M8x1.25 Bowden Pneumatic Connectors

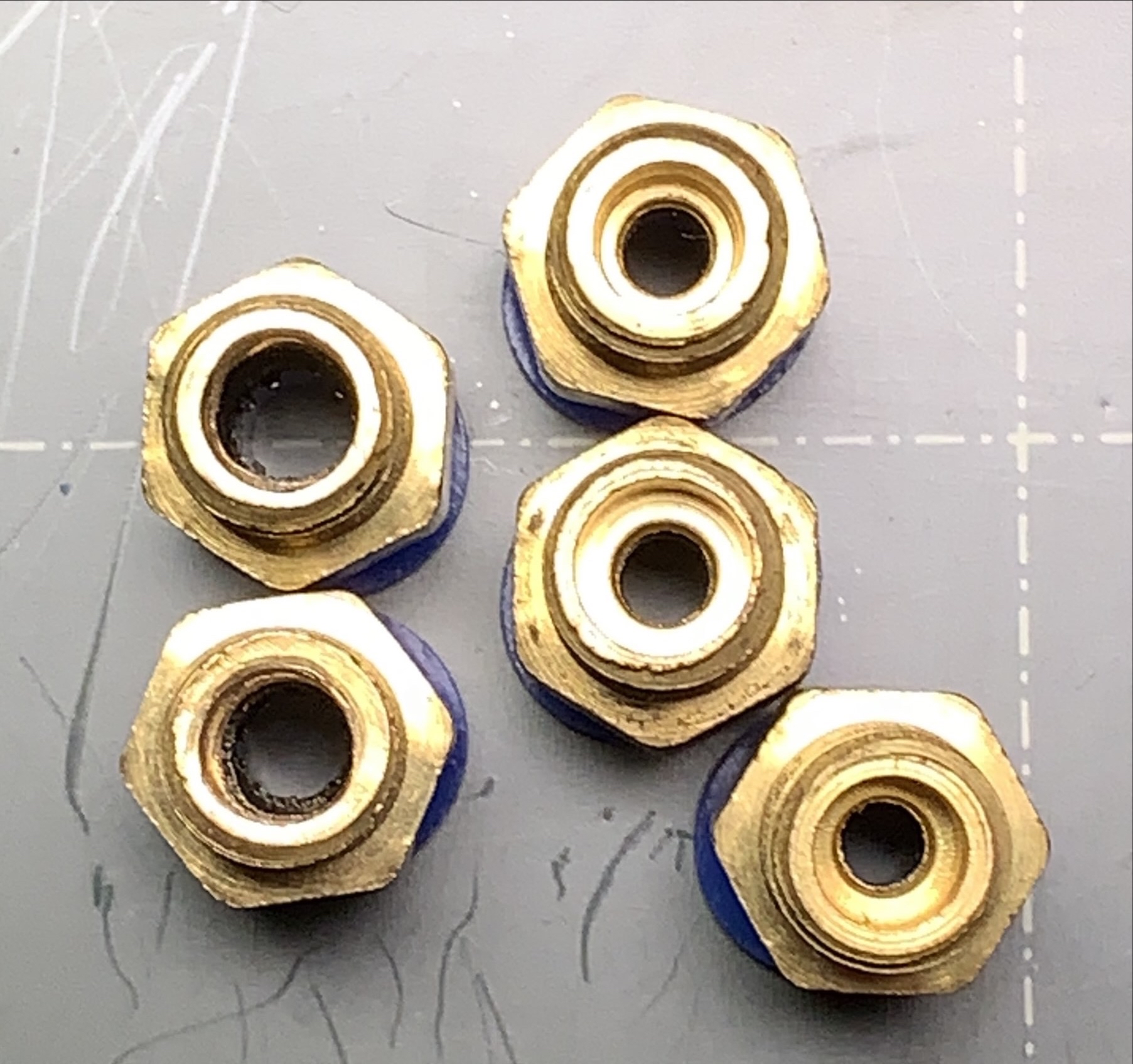

Just a heads up for anyone ordering the PC4-M8x1.25 connectors from AliExpress store DuoWeiSi mentioned earlier ( https://www.aliexpress.com/item/32967678995.html) : I received 20 of them today and the bore in the middle part is less than 4mm on all of them, it varies between 2.5mm and 3mm. It's nothing that a few minutes with a Dremel type tool won't fix but it's a bit annoying!

The two on the left I drilled/filed out, the three on the right are as they were.

Oh, and hello everyone! First post 🙂