RE: Different Hotends

@kevman

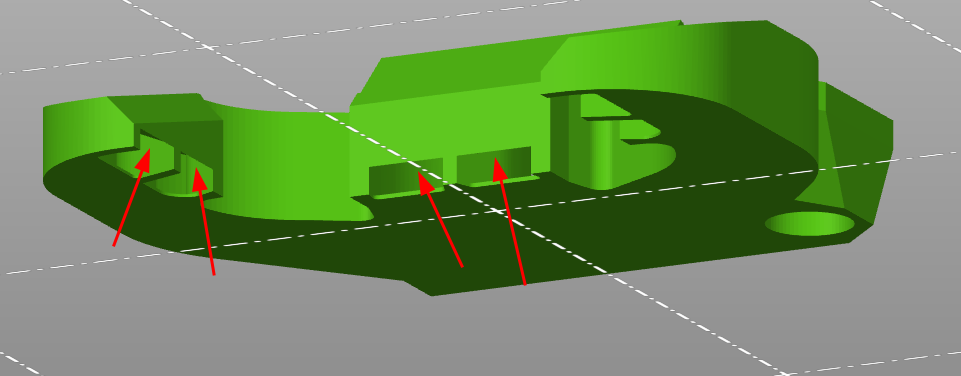

The x-carriage mod is part of the fan shroud mod. Some advantages are better overhangs, better details on small parts, and just cleaner prints altogether. I have prints from both and can say that it does make a visible difference.

Here are some examples of where I saw the most improvement:

Thanks for the input. Definitely worth it! Is it simply 4thonylin's piece and the bed cover ? does it need to be printed in PETG

RE: Different Hotends

@kevman I would recommend PETG in general for parts on the 3d printer for the better material properties and ASA for the fanshroud due to the close proximity to the heaterblock. ASA has been printing very well for me without an enclosure with only a faint odor.

One thing to note is that when printing PETG prints with the x-carriage mod, you may want to bump up the fan percentage slightly since the air is more evenly distributed, it's not as fast flowing as the original one. I've noticed 40% min and 60% max speed (from 30-50) to handle most prints fine. PLA you are just on 100% so you get the even distribution.

RE: Different Hotends

so far the mosquito upgrade has been amazing! my print quality and reliability is on point. Thank you for all that helped pioneer this upgrade. I hate that I had to invest so much more to fix an inherently flawed printer, but I will move on and enjoy my printer finally.

RE: Different Hotends

@kevman That's great to hear! Glad the upgrade is working well for you. Definitely agree that it is unfortunate that the hotend was flawed to being with. Hopefully this gets fixed by Prusa with maybe a MiniS.

RE: Different Hotends

I reprinted the fan shroud in Prusament's PC Blend, natural color to help with heat reflection. Hopefully this will be heat resistant enough to be permanent. This PC is amazing though, going to use it for anything functional. It was very easy to print. I'll probably make an enclosure for large pieces but I had no issues with the small shroud. Overhangs and bridges came out perfect.

Btw, I'm getting uncomfortably close to the 2 plate alignment screws, especially with the textured sheet. Has anyone modified those? They appear to be riveted in. Might grind mine down ~1mm or so.

RE: Different Hotends

@malcmcm Oh wow, the PC came out great with the fan shroud. I might consider getting a roll to try it out with smaller pieces. The clearance is definitely super tight, haven't seen an issue but it does cause some slight anxiety for me as well. It's a tough balance between cooling and clearance though. I've tested full bed prints and it clears fine. Just have to baby the first layer to make sure it works well 🙂. I do wish those bed alignment screws were screwed in instead of rivetted. Thanks for sharing your results with using the Prusament PC blend.

Did you have to do anything special to print PC Blend or was a textured bed with IPA cleaned fine?

RE: Different Hotends

@4nthonylin

I used the provided glue stick on the textured sheet and it worked great, came off easy and didn't warp. I've also printed directly on the textured sheet without glue and that worked just fine too, came off easy after cooling. Both times I just cleaned with IPA. I find that I sometimes have to clean the textured sheet with soapy water, especially after 2-3 PETG prints.

I probably wouldn't print PC on the smooth sheet without the glue stick (or really at all, I like the textured look).

RE: Different Hotends

@malcmcm Great to know, I ordered some PC blend, excited to give it a try!

RE: Different Hotends

Has anyone spent time tuning their Mosquito? I have been printing a lot of PETG and the prints are great, but can definitely be refined. Beyond PID tuning and playing a bit with the fan speeds, I haven't found much time or will to do a proper tuning. Hoping someone else might have put in the work, so I don't have to 🙂

Anyways, I am about 100hrs in with the Mosquito and new fan shroud. Thanks everyone for your help!

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Different Hotends

Quick question, is the cold pull procedure the same with the Mosquito hot end ? I don't need to do one yet, but curious. I have so far had one print fail due to the spool getting stuck!! haha I'll take that over clicking.

RE: Different Hotends

@benji I have looked into it but have never been able to substantially improve results over the stock settings (other than manipulating the fan settings). One of these days I'll look into sitting down and tuning for PETG to reduce stringing. Slightly off topic but I was also looking into doing the Silicone Bed Levelling mod but cannot source the M3 low-profile locknuts. Any suggestions?

@kevman The cold pull procedure should be the same as the stock as shown here: https://www.help.prusa3d.com/en/article/cold-pull-mini_126399

RE: Different Hotends

@4nthonylin

I just moved the guide to Github and you can find the answer to that and perhaps other questions there: https://github.com/bbbenji/PMSBLM (WIP, PR's welcome)

Unverified low-profile M3 nylock Amazon source: https://www.amazon.com/gp/product/B003Z6VHE4/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

What I did was I just sanded down a single nylock by hand. Only one is required to be low-profile (center back).

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Different Hotends

Also if you're in the US, McMaster has loads of options for thin nylock nuts, even Mil spec ones if you wish. They are imperial size but I think 4-40 is the same as M3?

https://www.mcmaster.com/nylock-nuts/nut-type~locknut/hex-nut-profile~thin/thread-size~4-40/

I haven't ordered any (not in the US) so this is untested theory

RE: Different Hotends

4-40 is NOT the same as M3. Its close and might work but then again it might not 🙂

I don't have a mini but can I just say you gentlemen are doing excellent work, I'm really impressed by all the effort that's gone into this and the speed which you are all iterating through design changes. If I *did* get a mini I would certainly be looking at doing this modification.

RE: Different Hotends

Just noticed something on SliceEngineering's Website: https://www.sliceengineering.com/pages/hotend-configurator

Saw there was a new page to get kits for your 3d printer and it actually looks like there might be a Prusa Mini solution from Slice which will be interesting. Hopefully the nozzle positioning will be similar to what we have now.

RE: Different Hotends

@neophyl

Good to know! But also, if it has the possibility of fitting, maybe someone in the US should at least try it out and report back. McMaster is the only place I've found that reliably has then nylon nuts in stock. The Axial brand ones are sold out everywhere. But then again if you only need 1 for the mod, way easier to just grind one down..

RE: Different Hotends

@malcmcm

Prusa uses metric threads everywhere. These M3 nuts, for example, would be suitable: M3 nut

M3 has an outer diameter of 3mm and a pitch of 0.5mm. 4-40 nuts have an outer diameter of 2.845mm and a pitch of 0.635mm. If you want to do it right, you take the M3 variant.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Different Hotends

I sucessfully printed a 5 hour print, which was impossible before the mosquito hot end. I strongly believe that it has solved all my issues so far. If anyone is considering this upgrade, do it! don't look back. Prusa should refund me the difference of the cost of the upgrade, the design of the mini is flawed IMO.

RE: Different Hotends

@kevman That's great to hear that the upgrade has solved the issues you were seeing! The mosquito is a little overkill but great for the convenience (one hand cold nozzle change) and better performance. People can look at the following:

Copperhead ~100usd: https://www.prusaprinters.org/prints/37263-best-prusa-mini-ever (One con is this mount seems to rely on a different fan, someone can probably remix this to use the stock hotend fan on the mini to avoid rewiring a fan)

E3DV6 ~60usd:

MK3S style: https://www.prusaprinters.org/prints/37428-mk3s-hotend-mod-for-prusa-mini

Alternative: https://www.prusaprinters.org/prints/28046-prusa-mini-v6-conversion-upgrade

There are probably are more available.