RE: Different Hotends

I am 99% done with the MK3S hotend conversion. It now prints with no errors during mesh leveling. Love it...

WOW! keep us posted when the last 1% is done 🙂

Would this be a more ideal upgrade vs a mosquito hotend ? I am debating what to do with my Mini.

I have never used the mosquito hotend, just the E3D V6 that is on the MK3. I think the E3D is cheaper. I wanted to use it because I have spares parts for my MK3 so I wanted to keep the same parts. For some reason the stock MINI hotend just kept giving me stringy prints, no matter the material or temperature...

RE: Different Hotends

@jeffrey-l15

Did you replace the MINDA probe with a PINDA or other temperature-sensing probe? Unless it's an earlier version- the color is different from mine.

RE: Different Hotends

@jeffrey-l15

Did you replace the MINDA probe with a PINDA or other temperature-sensing probe? Unless it's an earlier version- the color is different from mine.

I did not replace the MINDA - it may be different color because i broke a couple pieces of my printer during this whole process and replaced them.

RE: Different Hotends

I did not replace the MINDA - it may be different color because i broke a couple pieces of my printer during this whole process and replaced them.

The MINDA/PINDA in your picture is super long. The Mini's MINDA is much shorter. The one pictured is the one you received with your Mini?

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Different Hotends

I did not replace the MINDA - it may be different color because i broke a couple pieces of my printer during this whole process and replaced them.

The MINDA/PINDA in your picture is super long. The Mini's MINDA is much shorter. The one pictured is the one you received with your Mini?

No. It is a spare one I had from my MK3 printer

RE: Different Hotends

@malcmcm

Please post your remix, I am waiting on my Mosquito to be delivered and still deciding on which mount I want to use. Yours sounds nice.

I'm still waiting on mine to be delivered too! I'll post the remix once I confirm it actually fits and works as intended.

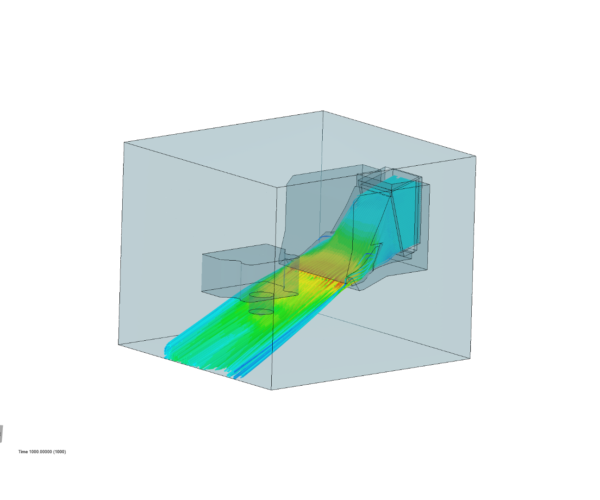

Image of drawing in F360:

Glad to see you updated the design! I did consider opening up the design to showcase the mosquito logo but decided to keep things simple for now. The block is close to the fan shroud however it seems to be doing fine! I do have a silicone sock installed and some reflective tape so that probably does help. I will probably reprint in ASA next time.

In regards to the offset, just make sure you zero the offset prior to autohome in the start gcode and then set the offset after mesh bed levelling is done. Then to be safe, reset the offset at the end gcode. The reason why is because the prusa mini has a bug when homing with M206 set. You can see here: https://github.com/prusa3d/Prusa-Firmware-Buddy/issues/693 the issue.

I have also been working on a new x-carriage with the RHD_Dreambox Fan duct here: https://www.thingiverse.com/thing:4217188 Planning on installing and testing it soon! Will post it some time however it is meant for the mount I currently use https://www.prusaprinters.org/prints/36643-prusa-mini-mosquito-mount . Can probably make a version of the attached duct to be compatible with the Prusa Mini stock which would most likely be close enough to @woraphot mount.

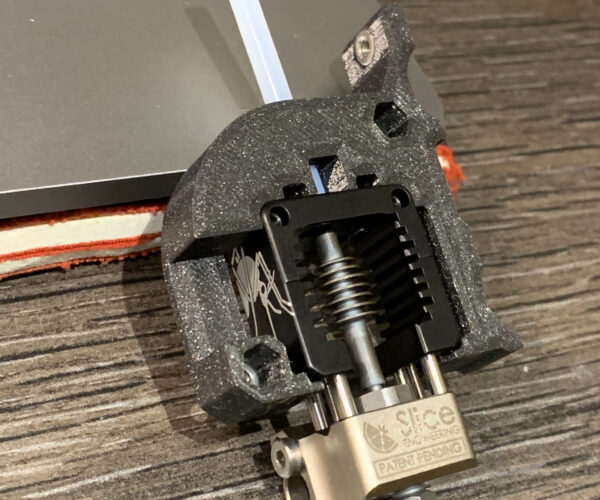

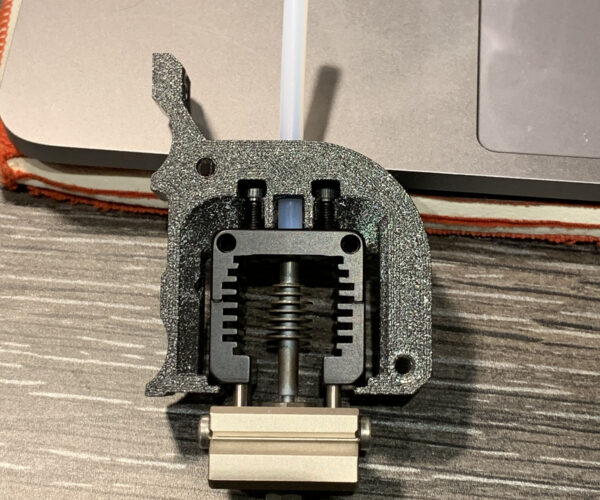

Here's a look at x-carriage and fan duct 🙂

RE: Different Hotends

@4nthonylin

That fan duct looks great! Please please, post when it is ready 🙂

Too bad I just saw your comment about the M206 not working properly this morning! I tried all night to get it to work and couldn't figure it out.. I ended up just changing the origin in slicer, it works for now. Also had to change the position of the initial primer line.

I've modified my remixed design again. I couldn't find a place nearby that had m2.5 bolts and didn't want to wait for some to ship to me. So I made it so you can use the hardware that comes along with the mosquito. The M2.5 bolts slide in from the rear and will be hidden by the fan duct. The top holes are just large enough for the 2mm allen key to fit. This clears up some room for the original mini brass thread fitting (M8 size). So now there is no need to go out and buy any hardware other than some M3 nuts.

I'm not 100% satisfied yet, but will put on prusa printers when I am.

RE: Different Hotends

@4nthonylin

That fan duct looks great! Please please, post when it is ready 🙂

Too bad I just saw your comment about the M206 not working properly this morning! I tried all night to get it to work and couldn't figure it out.. I ended up just changing the origin in slicer, it works for now. Also had to change the position of the initial primer line.

I've modified my remixed design again. I couldn't find a place nearby that had m2.5 bolts and didn't want to wait for some to ship to me. So I made it so you can use the hardware that comes along with the mosquito. The M2.5 bolts slide in from the rear and will be hidden by the fan duct. The top holes are just large enough for the 2mm allen key to fit. This clears up some room for the original mini brass thread fitting (M8 size). So now there is no need to go out and buy any hardware other than some M3 nuts.

I'm not 100% satisfied yet, but will put on prusa printers when I am.

That's a great solution! I was thinking if I could do something but never thought about having the screws slide in. The posted a M8 version that does work but your solution is definitely a lot cleaner. M2.5 screws were hard to find too, bought some off o McMaster but your solution is way more elegant. Might switch to your version next time to have the color of the fitting to match and hide the screws too.

I plan on posting it once I get it installed and verify everything works.

RE: Different Hotends

I have posted the fan shroud upgrade: https://www.prusaprinters.org/prints/37368-prusa-mini-mosquito-fan-shroud

Let me know if you find any issues! Still tweaking some of the geometry.

RE: Different Hotends

I've posted my remix as well https://www.prusaprinters.org/prints/37387-mosquito-mount-for-prusa-mini

Will try your shroud tonight!

RE: Different Hotends

I love all the contributions here. Thank you all for your efforts. I'm trying to figure out what woule be the easiest path for me to upgrade to the Mosqito. I want to apply the most minimal changes to see if I solve my problems then I will llook into some advanced ones. Thoughts ?

RE: Different Hotends

@kevman

i have uploaded my MK3S hotend for the MINI in case you want to check it out

RE: Different Hotends

@kevman

i have uploaded my MK3S hotend for the MINI in case you want to check it out

Very nice!! Are there any G-code changes that need to be run for this. looks pretty nice

RE: Different Hotends

@kevman

i always generate my own because I have my own settings. I set that gcode using a MK3S using Prusament PETG

RE: Different Hotends

@kevman

i have uploaded my MK3S hotend for the MINI in case you want to check it out

Very nice!! Are there any G-code changes that need to be run for this. looks pretty nice

if you mean "any gcode changes for the Prusa MINI", then no. I use the default settings in PrusaSlicer for Prusa MINI with this hotend setup.

I would caution, since you are changing the MINDA, that you go through all the setup settings and first layer calibrations

RE: Different Hotends

I just posted my remix of @malcmcm 's mount. I didn't care for the cutout for the Mosquito logo but really liked the mounting method compared to the original. Printing now. Mosquito should be here tomorrow.

https://www.prusaprinters.org/prints/37447-prusa-mini-mosquito-mount-remix

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Different Hotends

Nice! I had that version as well, should have posted it originally, sorry! I've uploaded it now, the only difference from yours is it keeps the back baffles the same as 4anthonylin's original. Wouldnt make a difference in the end though.

To add to the choices, there is also a design on thingiverse that looks very simple, it tries to get as close as possible to the original nozzle spot. https://www.thingiverse.com/thing:4201537

@kevman

There are trade off's with each mosquito mount, it makes it hard to choose and there is no right choice. Since the mosquito nozzle position is so different from the Prusa Mini, and the Mosquito heater block is larger and asymmetric it makes it nearly impossible to make do a simple swap for the original. You either try to keep the nozzle position constant (and therefore place it very close to the fan shroud and have cooling issues) or you keep the fan cooling zone constant (and have to make massive offset changes). I personally chose to use the stock fan design and start with 4nthonylin's and just adjust the offset (but now I'm going to use his fan shroud too :p). But don't be afraid to make some changes to the mini, the printer is pretty easy to understand and modify once you get started.

RE: Different Hotends

I've run into a small problem with the mosquito mount. With the Y-offset for the mount I'm using so large (-6mm), after realigning the origin point so it prints in the center of the bed, the nozzle cannot reach the entire extent of the Y axis. The linear bearings reach their limit of movement about 3mm from the actual print area, in the northern part of the bed.

I think there are 4 possible (good) solutions to this problem, and I'm weighing the pros and cons of each.

1) Re-adjust the Mosquito mount to make the offset more reasonable (~1-3mm). The downside is the nozzle will interfere with the flow of the stock cooling fan and would require a new xcarriage/fan shroud design, such as 4nthonylin's RHD but that too would have to be modified.

2) Re-printing the Y carriage (the piece that connects the heat-bed to the linear bearings) with a 5-6mm offset to compensate, in order to move the whole bed forward. The downside is the mesh bed leveling procedure would be slightly off (I think) and may require moving the MINDA a similar 5-6mm to compensate. Interference with the heat-bed cable cover more likely. Could possibly open a new can of worms.

3) Reprinting the buddy board housing so the Z-assembly can be moved back more. Similarly as above this might require MINDA adjustment and also seems like messing with the buddy board and whole z-axis assembly is not something I want to get into right now.

4) Simply scooting the PEI sheet forward every time you put it on. Downside: Inelegant? ugly?

Has anyone else noticed this issue when using 4nthonylin or my remixed mount?

I feel like I'm leaning towards solution 1, and just doing 4 for now.

RE: Different Hotends

@malcmcm

I see the same issue, ~3mm offset which I am fine with now but would like to tackle in the future. As noted, there was a large Y-Offset to prevent interference from the stock x-carriage cooling duct. Since I haven't seen the need to print 180x180mm, I thought that the 3mm was negligible for now.

For the heatbed cover clearance, I have a lower profile version here: https://www.prusaprinters.org/prints/37499-prusa-mini-low-profile-heatbed-cover if you were interested. It prints the cover inline with the 4mm screws for lining up the spring steel bed sheets.

In regards to your solution:

1) I plan on making a remix of both my fan duct and mount with the goal of maintaining the original nozzle position however I probably won't get to it for a while since the 3mm loss isn't a high priority to me.

2) This is an interesting idea! You would have to move the MINDA probe, I don't think that modification would be that crazy. There should be no interference if you use the low profile heatbed cover though.

3) This seems to be changing a lot more now So I would probably advise that.

4) That depends on how often you require the complete build plate! If you only use it once in a while then should be fine.

Totally agree, 1 would be the way to go, 4 works as a short term solution as of now. If you don't mind me asking, what are you printing that requires the full build plate?