RE: Bondtech Extruder for Prusa MINI

@peter-susan

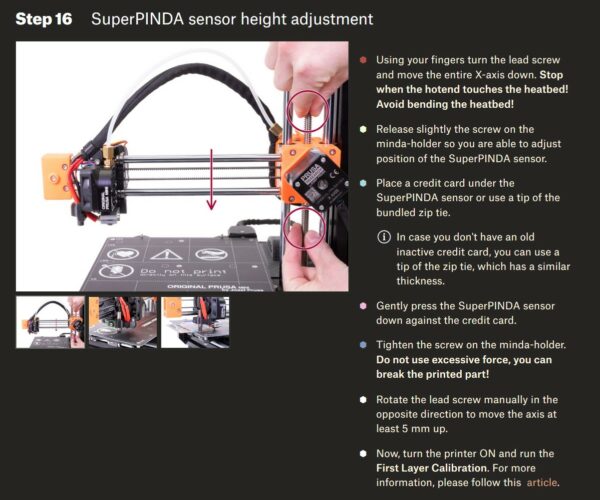

Just to be thorough, are you removing any steel sheets, lowering the Z axis to its bottom limit by hand, and then adjusting the SPINDA height to be ~1 credit card thickness above the bare print bed?

When I did this, the first card I grabbed actually contains metal, and that card seems thicker than average to me. For this reason, I set it aside and used a very standard, all plastic card. With the Z axis lowered, card on the bare print bed (no steel sheets, and work towel moved aside,) I set the SPINDA height, but when trying to remove the card, it was held in place by pressure from the SPINDA. I suspected this would amount to the sensor being too close to the bed. It is difficult to make fine adjustments to the SPINDA height, and I found myself overshooting each correction I made. To get it done, I inserted a small flat head screw driver into the seam of the part that clamps the SPINDA in position, and rotated it a bit to somewhat better free up the SPINDA, which allowed me to make finer adjustments. I finally got it set so the sensor was touching the card, but the card also slid out freely when I removed it. That's it. I set it the one time, calibrated, and it's been a new machine since. Note, I do not have my Bondtech parts installed yet.

RE: Bondtech Extruder for Prusa MINI

@24kjames

I used a 0.9mm file gauge. To be honest I don't understand why does it matter to remove the sheet or not? You're basically adjusting the height difference between the nozzle and the probe... Yes, the fine adjustment is finicky, but I'm sure it does not matter too much, just to be in the ballpark. I'm just wondering why does the self-test fails when I get the SPINDA higher? What does the Z axis test actually measures?

RE: Bondtech Extruder for Prusa MINI

This might help:

https://help.prusa3d.com/en/article/p-i-n-d-a-sensor-testing_2091

--------------------

Chuck H

3D Printer Review Blog

RE: Bondtech Extruder for Prusa MINI

@peter-susan

First, thank you for posting photos of your printer output. As is said, "a picture is worth..."

Now, it's an interesting question you have, and I too am curious, some what. But primarily I am interested in having a functioning printer. The minutia that help build my larger understanding, I trust myself to pick up along the way. When I want my printer to function (and this is all I want,) I refer to the documentation, and these forums. I guess I'm a, "print now, ask questions later," sort of guy.

Excellent documentation is often taken for granted, and documentation in general is, popularly, disregarded altogether. While I'm no stranger to figuring things out in the dark, RTFM is my key ingredient for success.

From the sound of it, this will help:

How to replace SuperPINDA (MINI/MINI+)

Particularly:

Of course this is my novice assessment, and you may be dealing with other issues, in which case this post may still serve others that find themselves here in the future.

But I do hope this helps you. Be it this, or some other solution, do please share another photo of that same print when you achieve perfect. Thank you in advance.

RE: Bondtech Extruder for Prusa MINI

Would any of you experienced something similar like this:

If yes, would you please help me fix it?

RE: Bondtech Extruder for Prusa MINI

@prusatester2020

The complete path from the extruder to the nozzle must be free of obstacles. It is also possible that the inner diameter of the PTFE guide tube has been squeezed in the area of the PTFE fastening by using compression fittings. I would check everything in this area for smooth running.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Bondtech Extruder for Prusa MINI

Just finished the disassembly/reassembly of the filament path and found that everything is OK. Finally tried with a filament and it went smoothly all the way from the extruder until the heat break. I suspect that it could be the extruder motor OR the heat break has a very small heating area, while the original Prusa Mini one has much larger area. The strange thing is that after a filament change for a few minutes (complete print of a 20x20x20mm squire in vase mode) everything is just perfect. As if a filament is building inside the heat break until it partially prevents the movement.

RE: Bondtech Extruder for Prusa MINI

@24kjames

I did both the Bondtech heat break and extruder at the same time using the Bondtech supplied PTFE hot end tube. Things worked for awhile and then it started started under extruding in fits and starts. The hot end tube had shrunk and a ring formed at the end of the tube preventing full retraction causing under extrusion.

That’s when I replaced all of the tubing, including the Bowden tube, with the blue more expensive (and I think higher temperature spec) Capricorn tubing. It certainly is stiffer and harder to cut the taper on the end. No problems since with many long prints. The OEM tube seems to be a “wear” item.

Joseph has said that the Mini was “built to a price”. Some of the decisions that were made to meet the price have caused problems. The heat break, extruder and MINDA are examples. I just wonder now if I did not need to upgrade the heat break and the better quality tubing would have been sufficient to fix the jamming.

I would have done the dual extruder anyway since one of the reasons for getting a printer was to print flexible filament and while not absolutely required, I’ve read it gives a higher success rate.

The Capricorn is not that expensive. You might want to give it a try.

RE: Bondtech Extruder for Prusa MINI

NOPE! It did not fix the issue 🙁

Replaced the PTFE tubes: the one between the extruder and the heat break and the one inside the heat break (this time it was a tiny bit longer) with a brand new ones – nothing changed!

Here are some photos:

- Heat block in details:

- Inside the heat break everything is clean and the PTFE tube is removed very easy.

- Printed the 40x40x30mm cube again in vase mode at 215C and it was OK. Then printer a small part at 215C. Finally started again the same 40x40x30mm cube at 215C – a complete disaster again!

RE: Bondtech Extruder for Prusa MINI

@prusatester2020

Have you tried a different filament or / and a Purge Filament?

--------------------

Chuck H

3D Printer Review Blog

RE: Bondtech Extruder for Prusa MINI

The gap between your heat block and fan block look large to me. 🤔 Is it all the way up as high as it can go?

RE: Bondtech Extruder for Prusa MINI

@prusatester2020

Have you tried a different filament or / and a Purge Filament?

Yes, as stated here: https://forum.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles/strange-extrusion-problem-using-bondtech-extruder-and-heat-break-on-prusa-mini/

...

- Change the filament type/brand – tried with PLA Prusament Mystic Brown, PLA Prusament orange and also 1 additional type of PLA – same result every time.

RE: Bondtech Extruder for Prusa MINI

The gap between your heat block and fan block look large to me. 🤔 Is it all the way up as high as it can go?

Yup, and also the Bondtech PTFE tube has the exact height.

I tried playing with different Flow Control settings at 215C. As soon as I raise the flow percentage (for ex. from 95=> 100=> 105 .. 120) the 3D print continues OK until is spoiled again after a few minutes. The latest I tried was set the Flow control to 120 on Prusa Mini. Everything started OK with a thick wall until suddenly again started under extrusion and splitting filament like marching ants (Mystic Brown looks purple then printed as a thin layer otherwise it looks brown):

RE: Bondtech Extruder for Prusa MINI

This is definitely the issue I'm having with these thin walled prints. I've tried multiple nozzles, cleaned, re-assembled, changed the thermal paste to multiple brands, dried the filament, adjusted the extruder pulleys, etc, nothing helped, only the cold pull for the next print... Already ordered Capricorn PTFE tube and a set of pneumatic connectors for it, but I assume, that the main issue is with the heatbreak itself and when the print requires retractions, the tube forms "microclogs" inside as it does not heat up that fast. Maybe that's why the higher temperature prints are succeeding more... I will test multiple retraction settings when I have a bit of a time after the christmas crazyness, but I assume the 70mm/s default Prusa retraction speed and the 3.5mm are too much. Don't know :/

RE: Bondtech Extruder for Prusa MINI

I lowered the retraction first to 3,2 and later to 3,0 and each time it eliminated more “blobbing” at the start and end of lines (this is with all Capricorn tubing”). It seems counterintuitive, but it worked.

Different retraction speeds did not seem to matter very much.

Just for giggles, try another brand new nozzle. At this point it seems you don’t have much to lose.

RE: Bondtech Extruder for Prusa MINI

@boatbuilder

Actually, besides the original Prusa nozzle, I've tried E3D hardened steel nozzle (huuuge failure.. it required 10+ C more temp to even produce acceptable prints, did not invested much more time into it, will do it later perhaps), also used the E3D brass nozzle and Bondtech's pure brass nozzle also. I'm waiting for Bondtech's plated nozzles and also ordered two Trianglelab plated nozzles too. Will see.

Worst case scenario I ordered a Trianglelab Dragon hotend and will rebuild the whole head with it, but I would be happy to avoid that and make this work :/

RE: Bondtech Extruder for Prusa MINI

I use VASE mode in order to have the retraction out of the equation - is this correct or the retraction is used even in this mode?

The proven fact is that the Bondtech heat break has much shorter High temp zone compared to Prusa heat break and this should be beneficial BUT:

What I suspect, and need proves:

Option 1. This new heat break requires more pressure from the extruder and the extruder motor could not support it. When a filament change occurs a tension is released from the motor and filament but later, especially in Vase mode, the pressure keeps up and the motor causes inconsistent movement. I already ordered a brand new Prusa extruder motor in order to put back the original Prusa extruder and check the results. Also an indicator put on the extruder motor could answer if this hypothesis is true.

Option 2. The Bondtech heat break does uneven heating that after some times leads to partial clogging and as a result a spitting & marching ants is generated on the 3D printed model as seen on my photos. This clogging puts stress on the extruder and rises the pressure. What follows after a few seconds later is a lot of filament spilled on the 3D model which causes bulbs. If I rise the temperature, the pressure is released for some time and the results are consistent until the problems appears again. I received the same result playing with the Filament flow factor.

Any other ideas how to explain this issue or how to prove any of the hypothesis?

RE: Bondtech Extruder for Prusa MINI

I'm also thinking something like your Option 2... When I will have some time with the machine I will try to figure out a way to prove it. Unfortunately I did not use vase mode, so no clue about if it does retraction or not, but you could hear it, if it does. Maybe between layer changes? Don't know really...

RE: Bondtech Extruder for Prusa MINI

also ... concerning the nozzle - I used the original Prusa Mini nozzle and now I use the E3D V6 Plated Copper Nozzle (1.75mm / 0.4mm) - same problem using both of them.

Option 3: The Prusa mini control of the extruder motor is not ok OR the current that is supplied to it is not ok.

RE: Bondtech Extruder for Prusa MINI

@peter-susan

In Vase mode there is no layer change just a consistent filament flow - it's named "Spiral vase" in Print Settings in Prusa Slicer. Try the demo 3mf file from my thread but sometimes you need to print it twice to reproduce the problem: https://www.udoma.org/tmp/PrusaMini/vase_cube_40x40x30mm.3mf