Which adjustment for changing nozzle diameter

Dear Folks,

I´m going to change the first time the diameter of my nozzle from 0.4 to 0.8mm.

Which adjustments do i have to change in prusaslicer to be able to go for a successful print!

Many thanks in advance!

Cheers, Bertl

RE: Which adjustment for changing nozzle diameter

Start with Printer Settings->Extruder 1->Nozzle diameter, Min & Max layer heights (for automatic layer heights). For print settings:

- Keep layer heights < 80% of nozzle size.

- Keep extrusion widths < 120% of nozzle size.

Those will get you started. As you get more familiar with the different nozzle settings, you can experiment with exceeding those values. Lots of notes on using different nozzles here.

RE: Which adjustment for changing nozzle diameter

Also, you may want to tune the max volume m3 as you are laying down much more plastic with a larger nozzle.

For example, on my old delta printer with a 0.4mm nozzle i used a max of 11mm3/s for pla, but needed to stay at 13mm3/s with a 0.6mm nozzle due to the heater not able to keep up melting the plastic.

A heat-sock also help contain the heat in the block instead of dissipating it to the air around.

Prusa Mini+ kit. BondTech extruder. FW 5.1.2

Prusa MK3S+ kit. Stock. FW 3.11.0

Prusa MK3S+, used. Stock. FW 3.13.3

RE: Which adjustment for changing nozzle diameter

Prusaslicer has presents for 0.8 mm nozzles now. For me they pretty much worked out of the box.

RE: Which adjustment for changing nozzle diameter

@fuchsr

that sounds good! Where can i find those profiles for different nozzle diameters?

many thanks, Bertl

RE: Which adjustment for changing nozzle diameter

@bobstro could you please explain me that in a bit more detail, because i do not understand exactly to which parameter settings in prusaslicer you are referencing:

"Start with Printer Settings->Extruder 1->Nozzle diameter," --> This is clear for where to find.

"Min & Max layer heights (for automatic layer heights). For print settings:

- Keep layer heights < 80% of nozzle size.

- Keep extrusion widths < 120% of nozzle size."

--> where can i find this 2 seetings in PrusaSlicer?

Many thanks in advance!

RE: Which adjustment for changing nozzle diameter

@3ddruckbertl

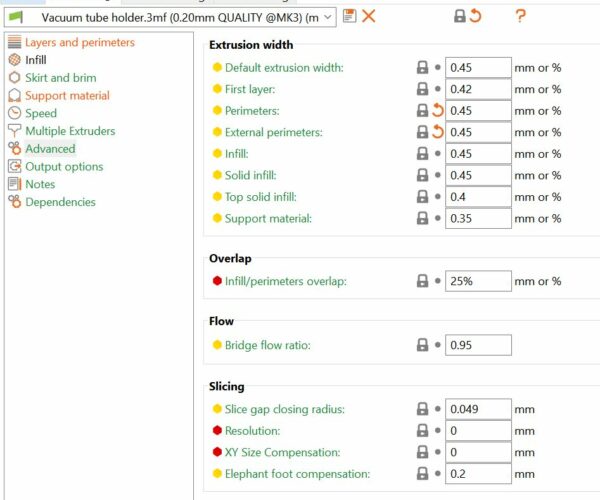

You go to the Print-Settings-Tab and then select "Advanced" (you need to be in Advanced or Expert-Mode). There you can change the extrusion-width. This should be between the nozzle-diameter (0.8) and around 120% of the nozzle. So this should be between 0.8 and 1.0. The default Prusaslicer-setting goes with 0.9 for the most parts and 0.8 for the top surfaces as far as I remember. You can also put "0" in the fields, so Prusaslicer chooses the line-width itself based on the nozzle-diameter. With this you can use the same presets for different nozzles without changing everything.

The layer-height is in the same tab under "Layers and Perimeters". There you can change the layer-height. With a 0.8-nozzle you should stay between 0.2 and 0.6. For example a - not recommended - 0.8-layer-heigt would result in a "square" line which won't have really good adhesion.

RE: Which adjustment for changing nozzle diameter

@3ddruckbertl you need to be in Advanced Mode, or Expert Mode. to see the settings

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Which adjustment for changing nozzle diameter

@3ddruckbertl

The Printing Handbook that comes with Prusa Printers covers this topic and provides a basic knowledgebase for selecting profiles and managing the Slicer interface expertise levels - about page 50 ...

https://www.prusa3d.com/downloads/manual/prusa3d_manual_mk3s_en.pdf

and more complete Slicer documentation is here ...\

https://help.prusa3d.com/en/category/prusaslicer_204

RE: Which adjustment for changing nozzle diameter

When I change the nozzle to 0.8 and slice the estimated time to completion doesn’t change. How can I get an accurate estimate of time to complete the print? I’d like to know how much faster it will print with a 0.8 nozzle.

RE: Which adjustment for changing nozzle diameter

It's not that straightforward. Print time depends on the model. I have printers with 0.4, 0.6, and 0.8 mm nozzles. For some models, prints take longer with larger nozzles, at default settings. Small models in particular may be limited by minimum layer time rather than maximum volumetric speed. But to get specific advice you're better off posting a 3mf project file here so we can review all settings and suggest improvements.

RE: Which adjustment for changing nozzle diameter

I really appreciate the response and any advice. I'm still learning but enjoying the curve...

I'm trying to print several Gridfinity baseplates and other utilitarian items for now. I have 0.25/0.4/0.6/0.8 brass E3D nozzles for the Prusa MKS3+. Since I'm printing so many I'm just trying to figure out a way to optimize print time since detail isn't super important for these. I can get around the PrusaSlicer ok but still learning what changes there affect printing. When I change the nozzle size and slice it doesn't seem to affect print times. I'm not sure if that is supposed to cahnge or not though it seems like it should.

Here is a link to the .3mf file I'm working on and similar to most of the others.

Thank you!