Weird outside moves when more than 2 perimeters in a layer

Hi all

I am triying to produce parts with more than 2 outside perimeters for some layers and i always get those moves outside the volume of the part, causing small blobs when the nozzle cross the outside part shell to go inside the part volume.

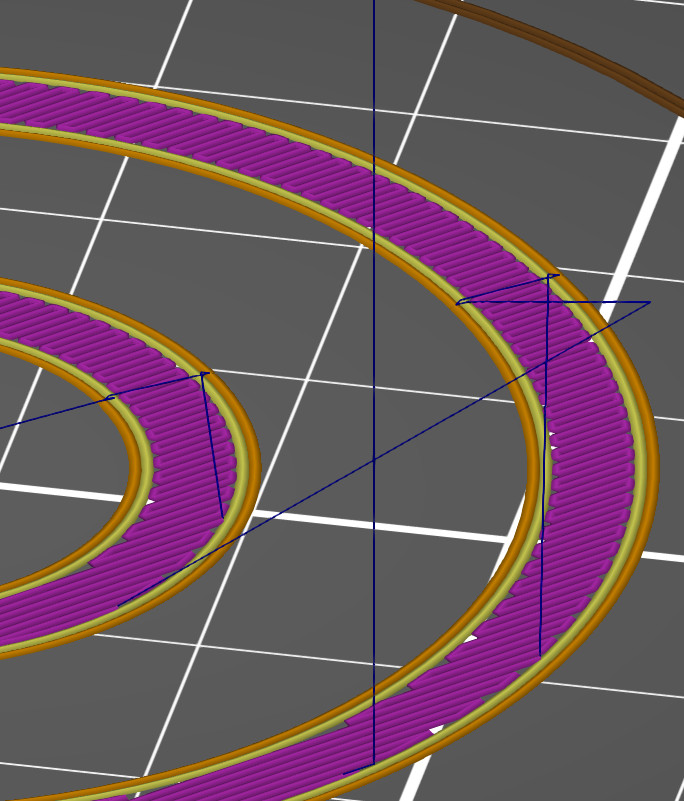

This is not my part but a simpler sample illustrating what i mean :

Can somebody explain how i can avoid those useless moves ?

RE: Weird outside moves when more than 2 perimeters in a layer

Have you tried the Print Settings -> Layers and perimeters -> Avoid crossing perimeters in Prusa Slicer?

You need to be in expert mode to see this setting.

Have a look at my models on Printables.com 😉

RE: Weird outside moves when more than 2 perimeters in a layer

@area51

Of course it's enabled and i can say that it's not a "wiping" effect either because wiping is disabled.

The part is just a ramdom part i draw to show you those weird moves, i disabled filling and top layer to see through .

RE: Weird outside moves when more than 2 perimeters in a layer

...and i'm using 2.2.0 version.

RE: Weird outside moves when more than 2 perimeters in a layer

If you reposition the z-seam, do those moves move with the seam on each layer? Try using external perimeters 1st as an option if the part doesn't have overhangs.

RE: Weird outside moves when more than 2 perimeters in a layer

@bobstro

Yes, those moves move with the seam on each layer.

No effect with the perimeter first parameter.

RE: Weird outside moves when more than 2 perimeters in a layer

Here's another sample, 1 layer thick, 2 "crowns", inside perimeter first, avoid crossing perimeter enabled.

Logically, it begins by the inside perimeter of the inside crown.

But as you can see, when the extruder comes to start the inside perimeter of the outside crown, there's this "outside the volume of the part" move before starting this perimeter.

Same part outside perimeter first :

As you can see, the part start by the outside perimeter of the inner crown.

It would be more logical that the extruder start by the outside perimeter of the outside crown, don't you think ?

But the main concern is this "outside the volume of the part" move when the extruder comes from the inner crown to extrude the outside perimeter of the outside crown.

RE: Weird outside moves when more than 2 perimeters in a layer

What impact is this having on print quality?

RE: Weird outside moves when more than 2 perimeters in a layer

@bobstro

It makes blobs when the extruder comes from the outside part volume.

But useless moves too...

Maybe it's not critical when you use rigid material but my application require flex filament which is prone to ooze a little.

I will try a modifier for the sections with 2 regions of my part to try to improve this.

Anyway, i know travel calculations are a bit complicated but i think this is an issue with our slicer which need to be improved.

RE: Weird outside moves when more than 2 perimeters in a layer

I'm having the exact same problem. I just have two perimeters (per layer) for the first 9mm of the print and it is only in those regions that I get the outside the perimeter moves. The rest of the print has one perimeter and is near perfect without any blobs so I know the rest of the settings are correct. When you look at the travel moves in prusa slicer it shows the travel outside the perimeter exactly where the blobs are occuring. Did you ever find a way around this? I tried a modifier to make the area in question solid but it still shows the same travel moves outside the perimeter.