Supports where no support is needed?

Hello, I want to print a cylinder laying on the side.

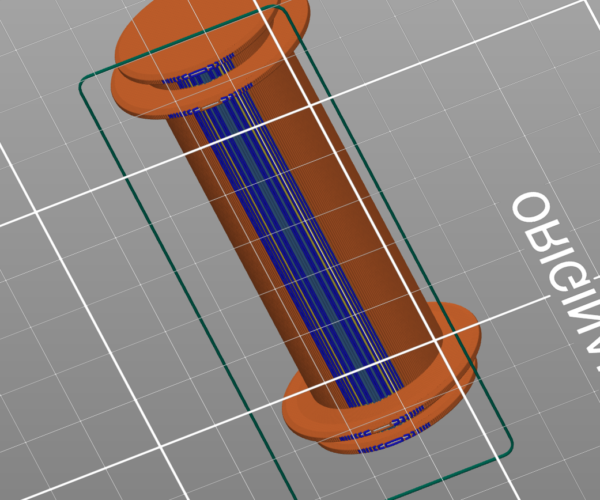

I understand that I need supports for the lower layers. When I activate them I see a small region which needs supports (blue):

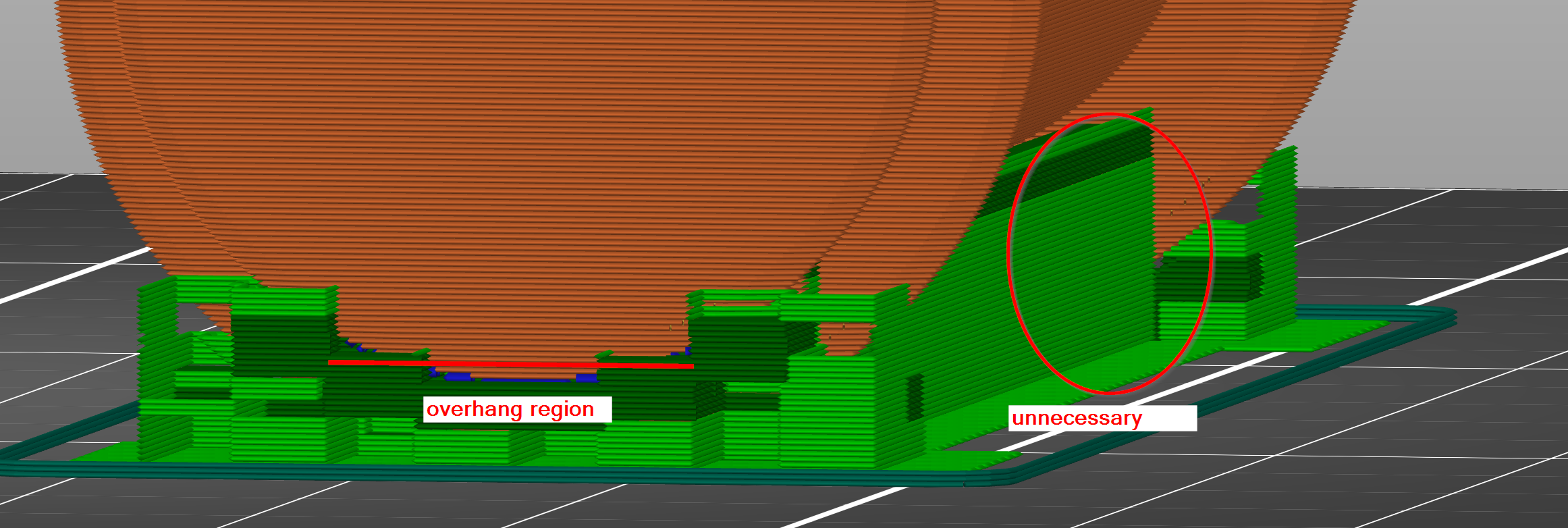

Somehow Prusa slicer adds much more support materials:

I use the standard 55 degrees for overhang threshold. Either the display of the overhang is incorrect or there is materials wasted..

Does anybody know how to manage to have support material only where necessary?

Best Answer by JSEngineering:

Thanks to Diem and Neophyl.

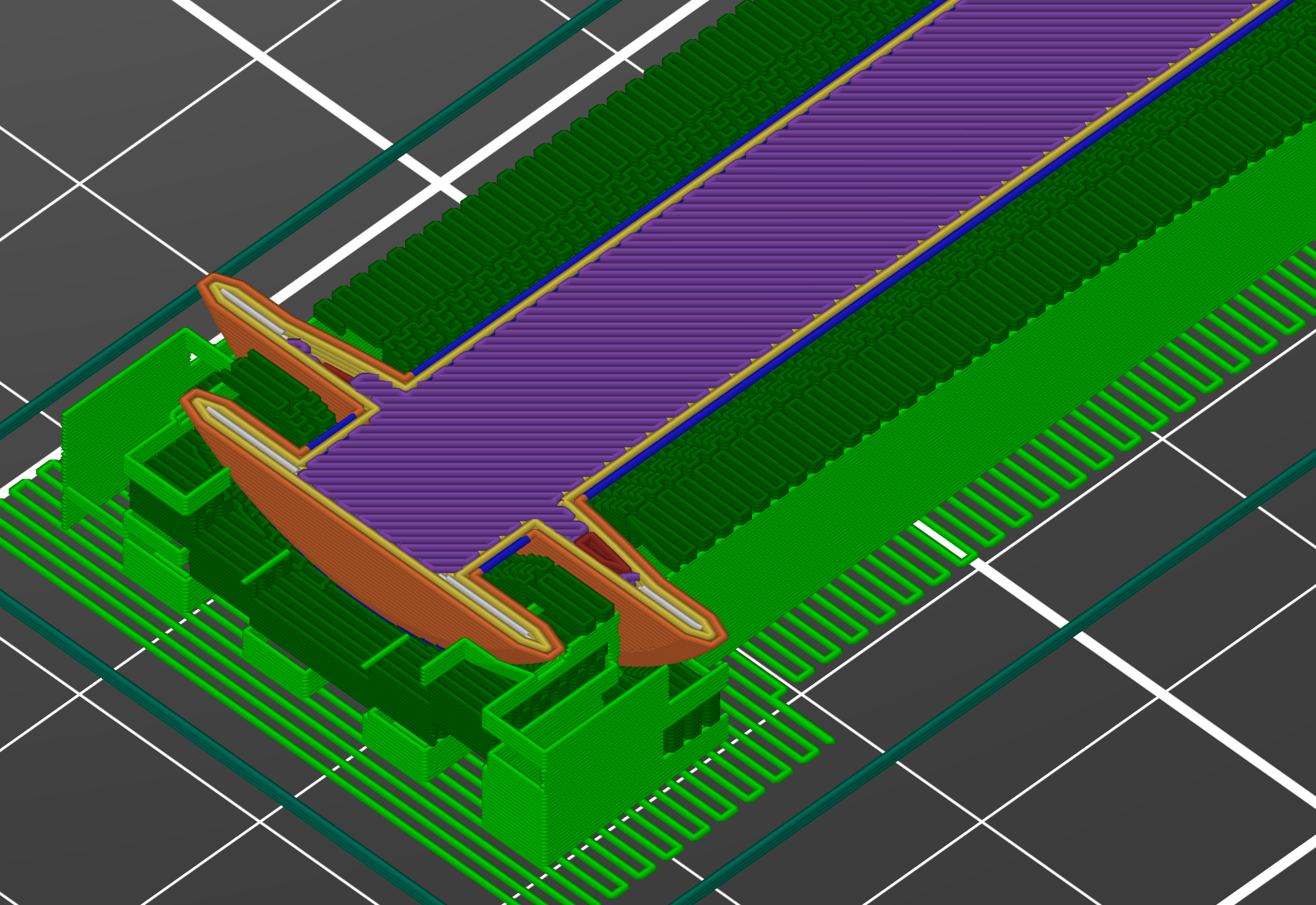

I managed to get it working with blockers and enforcers. First I used the Paint-on-supports->Autoset_by_angle->block at an angle of 60 degrees to block more than all potential overhanging surfaces and on top of that I used the same tool to enforce all surfaces of only up to 25 degrees.

Additional information

In this picture you see the highest layer marked as overhang perimeter (blue) and the excess support material reaching far away where the external perimeter material of my model could hang down.

Isn't the sole purpose of support materials to avoid bending down overhanging perimeter material?

You can paint-on support enforcers and blockers then enable support for enforcers only.

Cheerio,

This has always been an issue. There are so many threads about it here and on github if you care to search. At the moment is PS (2.3.x and earlier) the support algorithm is very aggressive. It grows out beyond alot. Thats just the way it is.

Its taken years but the upcoming PS2.4 is supposed to have extra settings to reduce this. We will just have to wait and see.

There are some things you can try though even at the moment.

First turn of auto and use painted on support enforcers along with setting it to For Support Enforcers only. Any support generated will still grow outwards but you can make the painted on areas smaller than you think you will need and see where it actually places support and then adjust the painted areas. There is a certain skill in judging this though that you only pick up with practice.

Secondly, you can make the Support pattern value smaller from its default ~2mm. Each time the algorithm grows outwards it expands by that amount. By making it smaller it grows out less.

Until 2.4 comes out and IF it lives up to reports then you aent going to get much better.

Beyond the art of placing support though I will say that printing a cylinder in that orientation is not going to work well. Even with supports the underside is going to be ugly as sin. Try rotating it at an angle so it sits somewhere around 45 degrees and then support the base. You will get a much better looking part as it will have less of the underside.

If you save your project (file>Save project as) and then take the saved .3mf file, ZIP it up into an archive and attach it here we can take a look, play with settings and positioning etc and then post back an updated example for you.

Paint-on-supports solved my problem

Thanks to Diem and Neophyl.

I managed to get it working with blockers and enforcers. First I used the Paint-on-supports->Autoset_by_angle->block at an angle of 60 degrees to block more than all potential overhanging surfaces and on top of that I used the same tool to enforce all surfaces of only up to 25 degrees.

Printing upwards failed due to non-removable supports

Hello Neophyl,

yes, I agree that printing this cylinder upright would yield better results - if there weren't those supports in those 3mm gaps. I tried a printed but after printing I couldn't remove those supports out of 3mm gaps between the rings. They stuck like hell on both sides. When I tried to increase the "contact Z distance" the gap became too small.

Do you have an idea how make supports less sticky to the external perimeters of my part besides the z distance? Can I e.g. decrease the extruder temperature or increase the fan speed before printing the bottom support layer and after the top support layer?

Please post the project and that way we can see. Also depending on print times we can also potentially run off test prints if the printer is free 🙂

Generally anything less than 0.2mm contact z will result in supports that are difficult to remove but without the part I cant quite seem to visulise what you mean about the gap being too small.