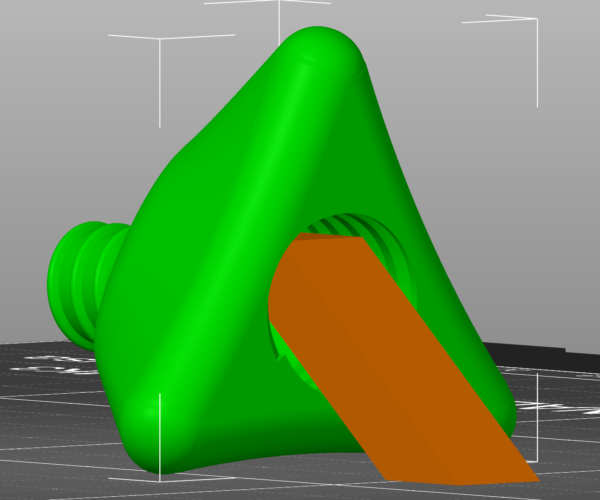

Support Block in angle shaped form

Hi everyone,

Challenge: The object has an inner thread. Due to stability reasons I need to print it in the way you see in the picture. With automatic generated support the top part of the inner thread is supported well, but obviously has its fundament on the bottom part of the inner thread. I've alread printed it and after removing the support material the threads are quite messed up.

Idea: I only need to support for the top part of the thread, so why not use an angled block with angle<50° and its base outside of the object.

What I tried:

- Used support block for the object, but after slicing still there is a vertical support block and not the sloped one.

- Used a second object in the form of the support block and hoped that the support material could "grow" from the top of the block to the top of the top of the inner thread

Please ignore the fact, that the outer thread part of the object, as well as the curvy shaped bottom part need support as well.

Attachment:

cap.zip.amf

RE: Support Block in angle shaped form

I cant seem to download the attachment. If I click on it it just takes me to another page and if I save as it just wants to download an html file.

Attachments need to have a .zip ending and either ber an actual zip archive or renamed that way (if you rename it please let us know so we dont try and unzip it).

RE: Support Block in angle shaped form

Thanks Neophyl!

I didn't get the point, how to edit my origin post, so I have to use this message, to send again the attachment

cap.zip.amf

It's a zipped AMF file.

Best regards

RE: Support Block in angle shaped form

Yeah you cant edit posts except in a VERY short time windows after posting. But it attached that time.

Attached to this should be a zipped up file too. Its a PS2.3.0 3mf project file.

Your original amf is there with painted on support enforcers showing how I would get it to add support between your sloped part and the Cap. I didnt define support for the external parts as you said not to worry about that. Once external support is added I think it will print but I dont think the threads are ever going to be good on it due to the way PS does overhangs. I was actually tempted to turn detect overhangs off as I think it will print better but thats up to you.

I've also added a second instance with how *I* would print it if I had to. 'Stability' is taken care of by adding a 1 layer thick part on the bottom which can be easily broken off afterwards. Unless there is some other practical reason not to the upright version on the left should print out much better.

There are several changes to 'default' settings too, like contact distance for the supports from a normal 0.15 profile. As you didn't post your 3mf project (which is the usual thing to do here) we don't know what other settings you are using. Posting the 3mf is much better as all your modifiers etc also come along for the ride as well as all your settings.

RE: Support Block in angle shaped form

Thanks again for the fast repsonse and your support.

I can open your .3mf file and it shows exactly what I was aksing for 🙂

I tried to redesign it from the scratch in a new file and failed. Unfortunatelly I don't know, what I'm doing wrong.

I've got several questions:

1. How did you create the angle shaped block within the cap.stl?

I clicked on "Add Support Blocker" and then I rotated the block with my desired angle. There the first challenge was to find the proper angle value. I guess the angles are refering to the world coordinates?

Second challenge was to cut top and bottom for a plane top and bottom. I needed to scale the block bigger than the cap.stl itself to use the Cut function. I guess there is no way to use the cut feature only for a indivdual support block?

2. How did you manged the support material only between the support block and the top thread?

I managed to created the support block shape, moved it in a test postion and used the paint-support-feature only above the top surface of the support block. Unfortunatelly the support material is still everyhwere else after slicing.

Hopefully this time, the attached file is in the proper format

RE: Support Block in angle shaped form

@johndoe

1) I didn't create the angled support block, you already included it in your amf. I just used what you already had. You managed to create the sloping shape before so you must be able to do so again. Also for things like this its easier to create it in CAD as part of the model. I do it with support for inside helmets all the time. You can then make your support object use one set of settings and the other support gets placed between that and the inside top of the object. Just like the example and it saves a lot of time and material. Now your model here is not anywhere near that so its not like you have to save material but the technique is the same.

Did you try printing it upright ? It will print much better that way.

2) You dont need any support blockers when you are using for support enforcers only. It only adds support below the areas you paint or otherwise define with the enforcer. Did you look at the area I painted on the example ? IF you move your point of view below the bed with the Paint tool active on your object and then use the Clipping function you can visually remove everything but the inner top surface. That allows you to see the area being painted. If you do that with my 3mf you will see that the painted area is not very big.

Supports will be generated for any area you define, however its still the normal support algorithm, which means its aggressive and will grow out from the defined area as much as it thinks it needs to. As such you need to be careful with the area painted for enforcement, make it small and slice. Then if needed make it a bit bigger and slice again until you get the coverage you want and it doesn't exceed the area. Also I notice you changed the contact distance to 0.15. Anything less than 0.2 and the support is likely to weld itself to the object.