Stringy internal NPT threads

Does anyone have any recommendations how to prevent internal stringing when printing internal threads (these are NPT threads) I've included the 3mf file with my settings (I just added the zip extension file at the end so it would upload). Ignore the supports at the bottom. I tried setting the Min Print Speed to 5mm/s from 15mm/s I even tried using the automatic variable layer height option and I still get stringing...It's PLA.

Best Answer by Stillpointx:

These setting worked for me using PETG

Rename zip file to .3mf

RE: File Attached

I'm not sure why the file never made it over but here it is again.

I've included the 3mf file with my settings (I just added the zip extension file at the end so it would upload)

So if you want to look at the file all you need to do is download it and rename it to npt_thread_test.3mf

supports and overhangs

I was hoping to avoid supports as much as possible I'm testing this with PLA but will be using PETG and supports aren't the easiest to get off PETG parts. Also the slicer shows no overhangs, trying to pull PETG supports from small internal threads would more than likely mess up the threads.

settings

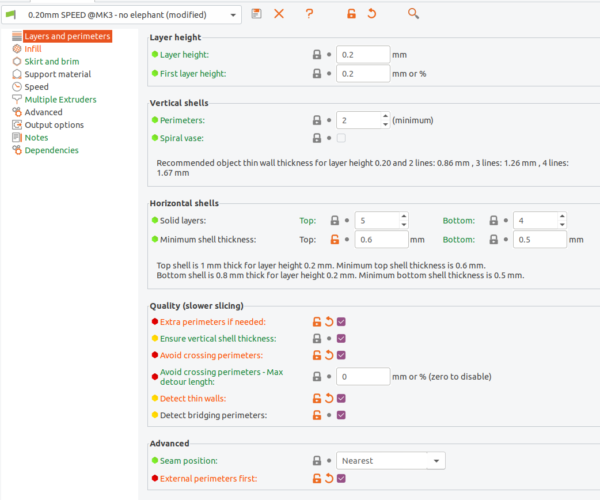

Try these settings:

Bobstro's settings:

- 0.25mm z distance.

- 75% xy distance.

- 3mm support spacing.

- 4 interface layers.

- 0.2mm interface layer spacing.

I think those are the key settings. Exposed support pulls off easily.

I hope this helps you.

--------------------

Chuck H

3D Printer Review Blog

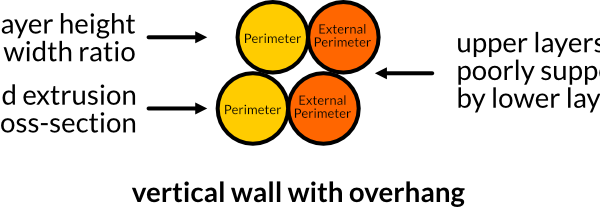

Not sure why its not showing as overhang but it should be. Its obvious from the print preview that the layers are not going to bond on those threads. Not enough below them so its not a surprise that they are just being dragged over as you pictured.

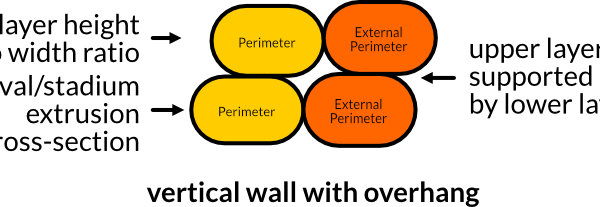

Personally I wouldn't use supports for the threads, I would however swap to using 0.1 as the layer height instead of 0.2. That will give you much better threads and actually have a chance of printing.

Lower layer heights

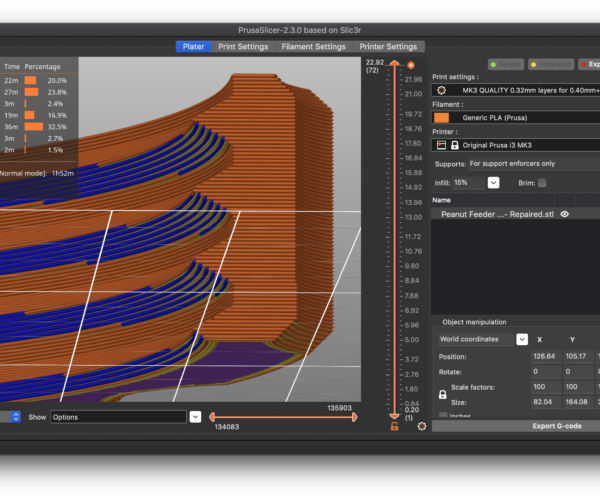

Just to add to @neophyl's comments: What you are seeing are those "strings" created when the tension of the nozzle moving around the opening is sufficient to pull the extrusion away from the wall. Your inter-layer adhesion is poor. This is usually due to excessively high layer heights.

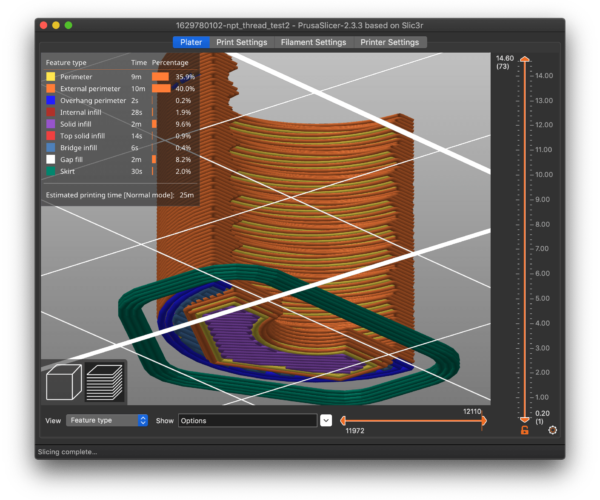

Slice your part, then spend some time examining it in preview mode before you try printing. Look for any blue overhang indicators. These either need to be eliminated, or you need to add support. Here's an example:

The problem is that those are overhangs and print with no lower layer to squish against. The extrusions come out round with poor inter-layer adhesion:

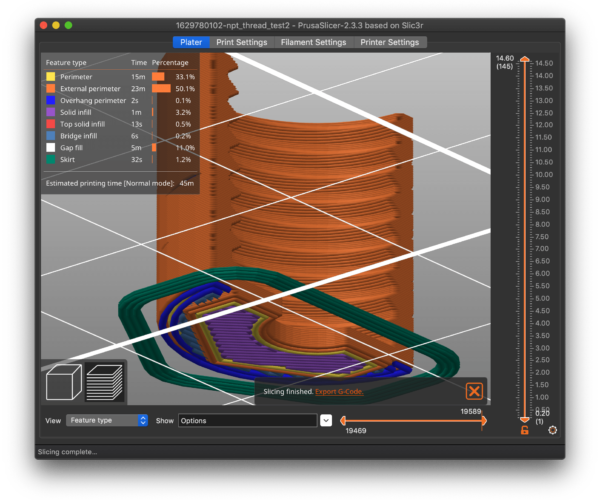

If you lower the layer height, you increase the ratio of support. A greater percentage of the new extrusion is supported by the layer below. You get more of the "squish" required to provide good surface contact for good inter-layer adhesion:

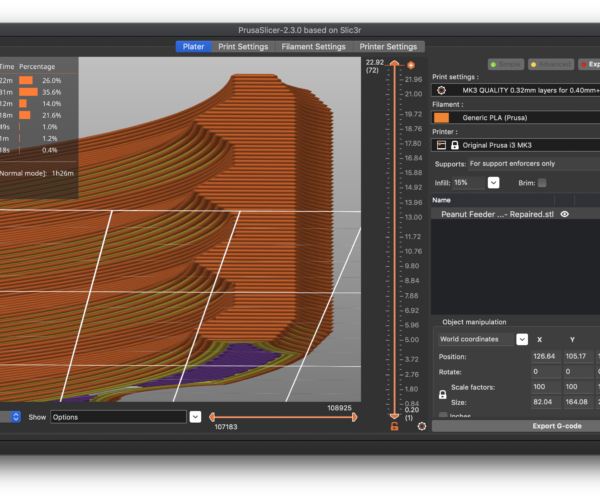

You can verify the improvement in your slicer preview:

Other things that can improve inter-layer adhesion are (in recommended order):

- Wider perimeter extrusion widths. You can use up to ~200% of your nozzle size if using quality nozzles.

- Reduce cooling slightly.

- Increase temperature slightly (though this may introduce stringing).

Visible results with lower layer height

I just cut your piece to show the internal details more clearly.

With your settings, the thread undersides are visibly rough. The yellow shows internal layers showing through.

Lower layer heights and increased perimeter extrusion widths show a visibly more consistent result:

I always find it useful to examine the slicer preview mode for tricky prints like this. It can often highlight problems before wasting time and filament with an actual print.

3mf

Can you post the 3MF and I will try to Print it?

--------------------

Chuck H

3D Printer Review Blog

RE: Support get stuck to the internal threads.

Thanks for the suggestion @cwbullet I tried your suggestion with PLA but the threads just get stuck to the threads and when pulled off it sticks to the threads and messes them up. I don't even want to think what would happen using PETG

I've included the 3mf file with my settings (I just added the zip extension file at the end so it would upload)

So if you want to look at the file all you need to do is download it and rename it to npt_thread_support_test.3mf

success

I do not have this issue. I have 100% success. Upload the file and I will try to print it.

--------------------

Chuck H

3D Printer Review Blog

Success

Sorry. I missed the file. I till try to dounload it and print ti tonight.

I do not have this issue. I have 100% success. Upload the file and I will try to print it.

--------------------

Chuck H

3D Printer Review Blog

Just remove .zip extension from filename

Sorry. I missed the file. I till try to dounload it and print ti tonight.

Remove the .zip extension. It's a 3MF just renamed.

I do not have this issue. I have 100% success. Upload the file and I will try to print it.

Try reducing the depth of the threads. If this must mate with a pre-existing thread try removing the peaks by cutting out a concentric cylinder just wider than the inner diameter.

Cheerio,