RE: Slicer generates support that hangs in the air

No it sometimes does that. Its why support related issues are a major focus of the upcoming 2.4 release. It may be that something in the project can be tweaked to avoid it in this case, however as there is no project attached we cant tell.

You must zip up a project file for the forum to accept it as a 3mf file is not allowed. Zip files are though.

RE: Slicer generates support that hangs in the air

Sorry, I've forgotten to attach the project. I have tested with PrusaSlicer v2.3.3 and the issue is there.

Similar issue is here.

Firstly that model is not very well designed for ffm printing. There are bits of layers sticking out all over the place. Secondly you have detect thin walls enabled. This setting is buggy and problematic at best. Turn it off unless you absolutely HAVE to use it. With that out of the way.....

As this has a mechanical fastening method we cant really use an xy compensation (like in your chest burster project) otherwise the connecting holes will also shrink. Mind you we could if we drilled them out a bit afterwards or used thinner connecting pins.

The majority of the model will print without support. There are a few overhang bridges shown in dark blue but even those at the size they are will print pretty well. The top ones on the base of the wand are more problematic but even there I think they will print with only some minor drooping. You could always trim that part off the top and test print just that section to see without wasting too much time or filament.

Also one of the sections is better printed the other way up. If you split to objects you can flip just that one over with place to face. It gives more surface area.

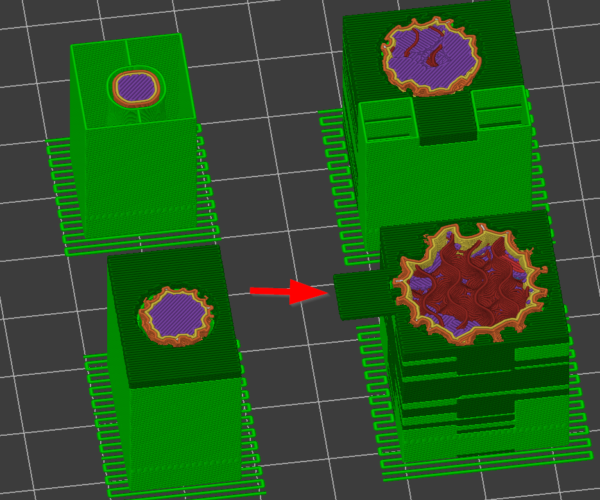

The only areas that really need support are the sigils. Like your other chestburster project you have your pattern spacing set to a very large value of 7mm. That's why the supports grow out so much. Bringing that down and using paint on supports gives a better result.

Also on the subject of the bridging perimeters. As they print with the extrusion width as thickness they will look a little droopy. Theres a great option in PS2.4 (not yet released) that makes the flow the same as normal called thin bridges. Unfortunately in 23.3 the only way to do this is to turn detect bridging to OFF. I sometimes do this once I've placed my supports if I think the thinner flow will work better than not having the bridging cooling values. If I was printing this out of pla then I would turn detect bridging off but in petg I'd have to test first. I'd be tempted with turning it off but keeping around 20-30% fan speed on all the time. Once again a good use for trimming the top off and printing it as a test piece.

If I had to print this using PS2.3 I would use the x/y compensation of 0.2 to thicken up some of those areas and then use connecting pins 0.4 smaller in diameter than the instructions call for. There's an area on part 2 anyway where the hole goes awfully close to the surface which the x/y comp will help with anyway. I would also turn the bridge detection off. This will still result in a couple of very time floating bits but the cleanup should be minimal and a lot less than will be caused by a bunch of support that doesn't really do much of anything anyway.

I've attached a 3mf with how I would try it first with the test piece enabled and the other parts turned off until I know that section will print.

Ps, this printed in the 2.4 beta is soooo much easier due to snug supports

Slicer generates support that hangs in the air

Neophyl, thanks for your answer!

Secondly you have detect thin walls enabled. This setting is buggy and problematic at best.

Probably you have already tried that, but if "Detect thin walls" is OFF the bug is still reproducible. It has to do with "Patterns spacing", as once I decrease it from 7 to 6, the issue disappears.

As this has a mechanical fastening method we cant really use an xy compensation (like in your chest burster project) otherwise the connecting holes will also shrink.

Drilling holes is not a problem, as usually have to do it anyways: I find it too hard to adjust extrusion multiplier and/or extrusion steps for all types of plastic hence resulting geometry is not absolutely the same.

The only areas that really need support are the sigils. Like your other chestburster project you have your pattern spacing set to a very large value of 7mm. That's why the supports grow out so much. Bringing that down and using paint on supports gives a better result.

I agree, 7 mm is too much. I used it for taller/larger models to save plastic. However I find your value 1.5 too small, probably range from 3 to 5 will be optimal. Supports also take time to print them...

This will still result in a couple of very time floating bits but the cleanup should be minimal and a lot less than will be caused by a bunch of support that doesn't really do much of anything anyway.

I agree with that. Initially I was trying to print with no supports but with brim. Unfortunately when printing was closer to the end (80% of the height), the nozzle was scratching a bit the top surface causing the towers (I'll call split parts like that) to bend and finally they were detached from the table. Widening the brim was not helping much. Probably I was seeing the top of the problem iceberg as it could be that my printing speed was too high which caused the towers to bend a bit due to table acceleration, which caused the top layer to be not equally distributed, which caused scratching... Or maybe I should raise the nozzle temperature so that it can "iron" such places. Anyway I failed few prints before I realized that maybe printing with supports (at least at some distance from the table) will help to make towers more stable. And then I've noticed that bug with a hanging support.