PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

So I recently made the switch from mainline Slic3r to PrusaSlicer, and I'm loving it. I particularily like the improvements made to PrusaSlicer in its handling of mesh modifiers.

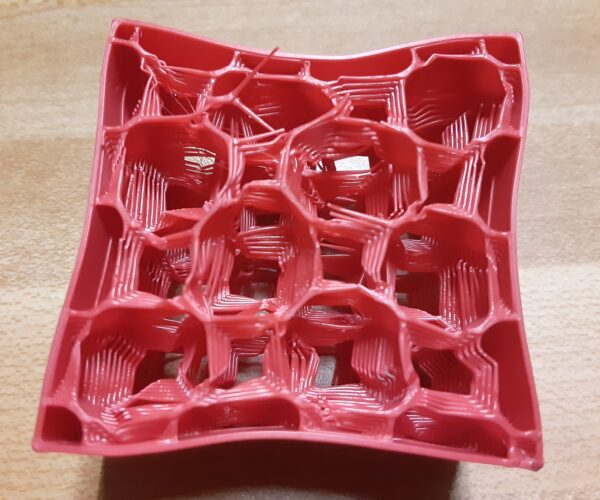

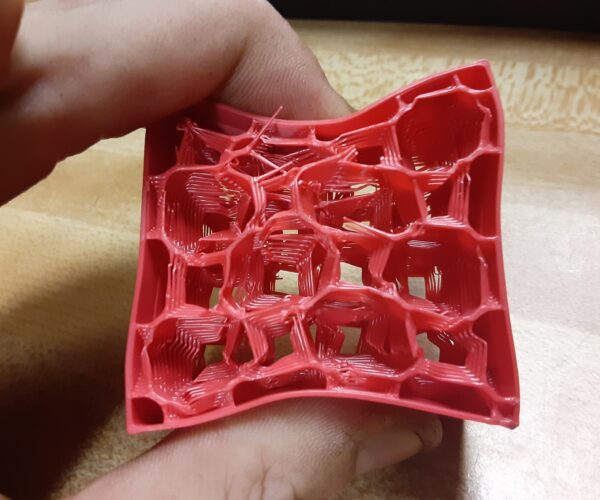

However, I have a major gripe with PrusaSlicer's implementation of "3D Honeycomb" infill. If you're not familiar with this pattern, Slic3r's implementation of it produces sparse-fill parts that have awesome compression strength in all directions. Parts built with this pattern also have far greater tensile strength in the Z-axis when compared to patterns like rectilinear, since there's much more contact area between layers and very few bridges. The main issue I see with PrusaSlicer's implementation is that the print direction alternates between each layer, instead of only alternating at the centerline of each new set of "cells." Alternating between every layer may seem like a good idea at a glance, since it eliminates the large voids surrounding each cell. However, the huge downside is that almost every toolpath is now a bridge. Not only does this significantly cut down on inter-layer adhesion and tensile strength in the Z-axis, but it also has a huge impact on compression strength in the X- and Y-axes.

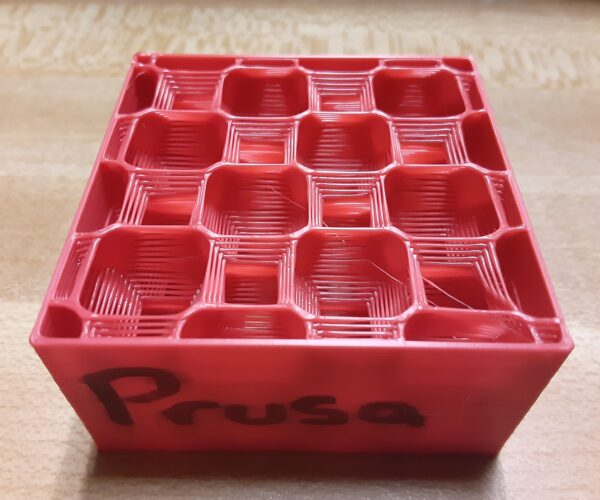

The test parts shown in the photos were both printed with identical parameters and a fill density of 5% and a 0.6mm extrusion width. The actual material consumption wasn't identical, but very close. As you can see, the bridges in the PrusaSlicer part form a sort of "teardrop" shape, with a thick blob on one end, and a thin strand on the other end. Most of the material used on these bridges is essentially wasted, since these toolpaths are only as strong as their thinnest section. This also means that there's virtually no inter-layer adhesion, since there's only one point of contact between layers at each intersection. I don't have the equipment to accurately measure compression strength, but I was able to easily crush the PrusaSlicer part in my hand. The Slic3r part was FAR stiffer in the X- and Y- directions, as well as corner-to-corner. Ultimately, I was unable to crush it by hand. I was also able to easily peel apart the layers of the PusaSlicer part, while this was much more difficult with the Slic3r part.

In conclusion, I think Slic3r's version of 3D Honeycomb is far superior to PrusaSlicer's. PrusaSlicer's version may be usable on parts with a higher density, but is far less efficient on large, sparse-filled parts with sub-10% fill density.

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

Good morning,

May I suggest that you raise this as an issue on the Prusa Slicer Github Page, where the developers look regularly.

They are unlikely to see this comment on the forum!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

It certainly seems that the two implementations have grown apart and are now very different from a mechanical point of view. Slic3r's implementation provides better strength in the z direction.

Should I print something in flex material I would prefer PS implementation as it will give a more uniform soft interior that is similar in all directions.

As @joantabb suggests, you should leave a new issue/feature request on GitHub for the developers.

Have a look at my models on Printables.com 😉

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

Stefan over on the CNC Kitchen Youtube channel did an infill shootout. IIRC, gyroid was best overall, but all failed to provide any advantage over simply adding perimeters for strength.

WRT PrusaSlicer, it may be a question of aesthetics versus strength. Gyroid is the new(er) hotness. Can't hurt to ask on GitHub though.

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

@bobstro

Of course you can can compensate for sub-optimal infill by adding extra perimeters and solid layers, but that's a band-aid solution. I'm mainly printing large foundry patterns, so eliminating a single perimeter without sacrificing too much compression strength can save hours of build time, and multiple kilograms of material. When it comes to large parts with huge volumes of infill, the efficiency of the fill pattern is extremely important. There's definitely a massive difference in the compression strength of parts printed with the two patterns.

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

[...] with huge volumes of infill, the efficiency of the fill pattern is extremely important. There's definitely a massive difference in the compression strength of parts printed with the two patterns.

And likely with gyroid as well. In the tests I've seen, none of the "3D" infills have surpassed gyroid in actual testing.

Again, can't hurt to raise the issue in GitHub, but I'd expect it to be treated as more of a feature request given that viable alternatives are already provided. If you disagree, just make a good case when you post there.

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

Given how recently Prusaslicer forked from Slic3r and the wildly different output is it possible that it's a difference in terminology? How is 3d honeycomb different.

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

Gyroid has become my go to fill pattern, unless there's a scenario in which it doesn't produce good infill, which I've seen with long and narrow parts that need to be arranged in certain angles on the print bed. Mind you, most of what I do doesn't require great infill strength but I find it easy to believe the test results that show gyroid being the most effective 3d infill.

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

Oops, I see you were referring to 3d honeycomb not plain old honeycomb.

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

Does setting Combine Infill Every to an absurdly large number? (you can't set it to 0)

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

Does setting Combine Infill Every to an absurdly large number? (you can't set it to 0)

You are still limited by nozzle size. Ideally, you want the layer height below 80% of the nozzle size for good inter-layer adhesion. While this might be pushed for infill, it still means your normal layer heights will be a fraction of infill layer heights, so print times increase.

It would be interesting to see results with a larger nozzle and "normal" perimeter layer heights. Print infill every 3 layers at 0.6mm, but external perimeters at 0.2mm using a 0.8mm nozzle for example.

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

PrusaSlicer Cubic infill looks like a possible substitution for Slic3r 3D Honeycomb as it has better z-direction bonding. The cons is that Cubic is a closed cell structure compared to PS Gyroid and Slic3r 3D Honeycomb.

Many applications have support for add-ins - it would be awesome if PS supported plug-ins for infill, surface, support etc. Maybe this will happen sometime in the far future...

Have a look at my models on Printables.com 😉

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

@bobstro

In my experience, gyroid fill starts to become really ineffective at extremely low fill densities (2-5%), and/or fast print speeds (+100mm/s). The great thing about Slic3r's 3D honeycomb is that it allows you to build extremely sparse parts at high speeds, due to the reduced number of bridges.

It's also worth noting that the "infill density" parameter isn't always consistent with the total volume of filament needed to create that pattern. For example, 3D honeycomb at 5% density generally uses significantly less material than rectilinear at 5%.

RE: PrusaSlicer's "3D Honeycomb" Infill is Sub-optimal

I feel like I need to clear up some misconceptions here...

It certainly seems that the two implementations have grown apart and are now very different from a mechanical point of view.

Both bits of code were written by me; the code implemented in current PrusaSlicer is from an earlier fork of Slic3r that didn't include the layer change adjustment. In other words, they haven't "grown apart"; PrusaSlicer's code is just older.

Stefan over on the CNC Kitchen Youtube channel did an infill shootout. IIRC, gyroid was best overall, but all failed to provide any advantage over simply adding perimeters for strength.

A better link for Stefan's infill shootout would be this one, where he tests gyroid vs the older alternating-layer 3D honeycomb (i.e. the one currently implemented in PrusaSlicer). I did comment on that video shortly after posting, asking about testing out the new pattern, but there was no response.

Does setting Combine Infill Every to an absurdly large number?

The PrusaSlicer version uses "bridge mode" for the infill, which I think ignores a few things relating to flow rate. I doubt combining infill every N layers will work at all. The newer code doesn't need bridge mode, because it's almost always printing over the top of something at an angle of approximately 60°. The only true bridging happens at the direction changes, and it's across the smallest gap in the pattern.

PrusaSlicer Cubic infill looks like a possible substitution for Slic3r 3D Honeycomb as it has better z-direction bonding

Yes, it's a similar structure (cubic vs bitruncated cubic). The main difference is in the stress points. The cubic infill is a rotated version of the rectilinear infill with full layers at regular intervals, so has similar strengths and weaknesses. The 3D honeycomb has air in all directions except for things that I call "vertical diamond spines", which are centred on the four diagonals of the squares. This should mean that stresses are better distributed to more of the structure, hence why it's harder to crush from all directions.

It's also worth noting that the "infill density" parameter isn't always consistent with the total volume of filament needed to create that pattern.

Yeah, sorry about that. The code was a quick fix [that got stuck for years], and I didn't see much point in trying to get the density right because it was easy enough to fiddle around with the density value. I've just submitted a pull request to PrusaSlicer to try to get the new code implemented, with additional tweaks to make it pretty close to the ideal density for cube structures (similar to rectilinear, better than gyroid). Hopefully it'll mean more people can try this out and see for themselves whether it's better or worse.