print setting speed does not affect speed chart on the plater

hi,

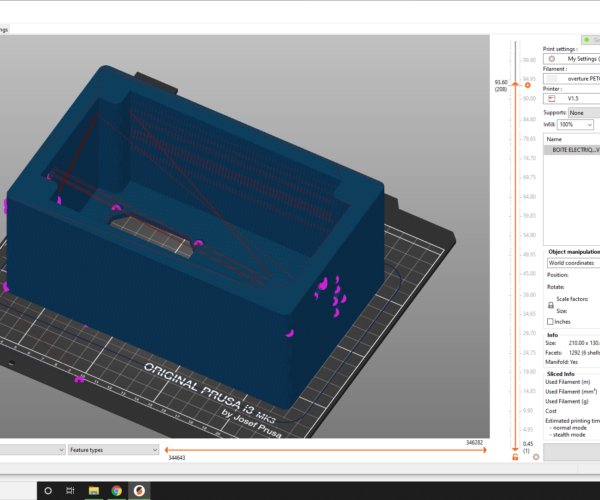

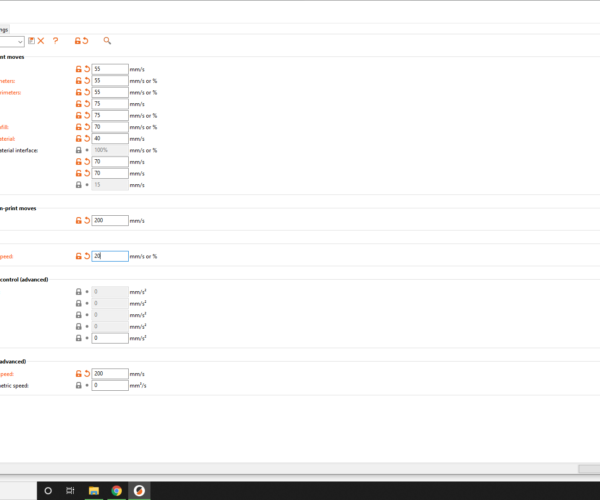

im having trouble changing the speed of my parameter. i am changing it in my print setting but it does not affect my part when i look it from my plater speed chart (see reference picture).

i am printing at a layer height of 0.65mm with a 0.8mm nozzle.

if someone could help me it would be great thank you.

RE: print setting speed does not affect speed chart on the plater

Please save your project then take the 3mf file produced and zip it up. Then attach the zip file here. It must be zipped or the forum won’t accept the file.

There are so many interacting settings that the 3mf is the single best way to debug these things. As with it we can slice with exactly the same settings and model/placement etc that you are using.

RE: print setting speed does not affect speed chart on the plater

@neophyl

hi,

here you go, if you could look at it and see if there is something wrong with it it would be great.

thank you.

BOITE ELECTRIQUE MOTEUR VORAN V1.6

RE: print setting speed does not affect speed chart on the plater

@rob29

Very simple one this. Try changing the preview from speed to Volumetric Flow rate. You will see that is also a solid colour too (except for the first layer).

The hotend on the printer can only deliver plastic so fast. Now it varies from plastic to plastic (even within a type) and it also varies on temperature, printer hotter and it can print more throughput, however your quality degrades etc. There's a few things that effect it, all working together. You have hit the MVS settings as defined under the filament > advanced tab at 8mm/3 a second.

Now the mvs setting in there is a 'safe' value worked out by Prusa for that filament. Depending on what quality you want and on your actual filament you can push that up. Bob would be the one to discuss that with as he did a lot of work testing options when printing ppe at the start of the covid outbreak.

The trouble is working out if you can push those settings with that model is going to be expensive in time and filament.

Also I hope you have your filament perfectly dialled in and you don't have even a slight overextrusion as printing it solid will magnify those issues. Expect raised bits and 'crashes' in the x/y axis as the extruder hits those bumps caused by filament variance.

There's also a very significant chance of it warping, especially with petg. although I think even pla would with a box that size and shape. You are probably aware of that but just thought I'd mention it 🙂

There are also several other settings you are using that strike me as unusual.

First layer extrusion width of 0.7 ? Why as your nozzle is 0.8. You cant realistically print with a width less than your nozzle diameter. Thats likely to lead to more plastic on the first layer. If thats your intention then ok but if you werent getting a solid first layer the normal fix is to squish it more using live z adjustment rather than changing your widths.

In fact ALL your extrusion widths look to be set up for a 0.6 nozzle and not a 0.8 one.

I don't think I have ever deliberately printed anything solid though. Upping perimeters to 6 with infill at 20% even with a 0.4 nozzle makes for very tough parts. 6 perimeters with a 0.8mm nozzle and I think that box could take my weight if I stood on it, and I'm not a small chap lol.

Anyway if you want to print faster for stuff like this then a high flow hotend might be a worthy modification to the printer. Normally for a high capacity you would use something like a volcano but thats a lot of work to mod a prusa like that and requires customised firmware. You might want to have a read of the dragon hotend thread in the general forum https://forum.prusa3d.com/forum/english-forum-general-discussion-announcements-and-releases/review-dragon-hotend/ its rather long but it looks like one of the dragon variants would be a drop in replacement that is capable of pushing through more plastic. Worth a read anyway.

Phil

RE: print setting speed does not affect speed chart on the plater

@neophyl

Hi Phil,

thank you so much for your help and your advices.

almost all my prints are 100% density because i print parts for industrial purpose and a lot of time we drill holes and put screw into the parts so if the density is not 100 the screws wont have nothing to hold on to. And also it assure me that the part is pretty strong so someone will not break it easily, even tho i know that i can have pretty strong parts with 20-25% infill like you said.

i will look into the dragon hot end it may be a good match for me like you said.

Again thank you for your help and have a great day.