Poor layers (only some)

Hi,

I have troubles with some of my layers using Prusaslicer 2.2.0.

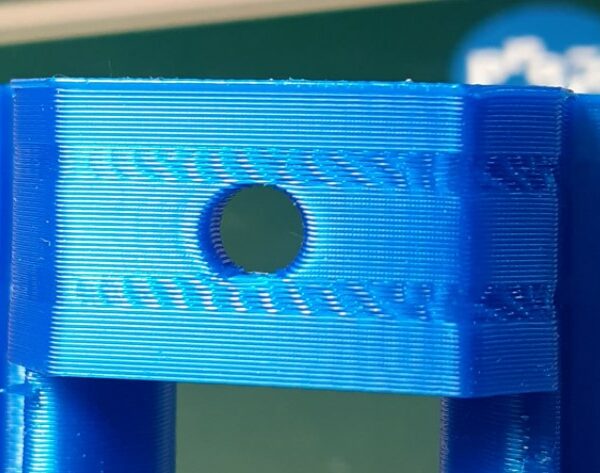

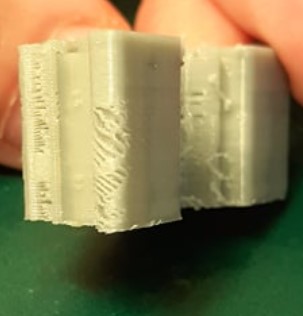

As seen on the pictures, some layers are pretty ok, but when there is hole in the model walls are becoming thin, with pinholes in and even with some weird helical shape on the right side

I moved to Prusaslicer from Symplify3D when on the same model, it did have similiar problems under and above the said hole, as seen on this photo

Any ideas what may cause the problem?

Best Answer by Neophyl:

There are many settings in that project that are sub-optimal for printing in PET. Most of the filament setting for example are from a PLA profile, pet generally only needs 30-50% cooling, running it at 100% is going to make for very weak parts. Also the volumetric limit is too high, again a value normally set for PLA.

Also the support is set to be far far too close, it will be VERY difficult to remove with those settings. One thing I noticed is that you had the solid infill threshold set to 70mm/2 which is causing it to be used around those problem holes. Thats the setting you were looking for, it should be set to 0 to turn it off which is what Ive done. Its sometimes useful for very small cross sections but I wouldnt set it above 5mm/s personally. Now I don't know for sure if that's what your issue is as the pic you showed would lead me to suspect that you have other extrusion issues. Alot of it may be done to the over use of the cooling fan though.

I have attached a modified project file with changes made to how *I* would try printing it (with your choices of infill etc), but I made all the changes to supports and the filament profile I would expect for a petg print. Also I have added a support enforcer and changed the support type for enforcer only. This stops the support being added for the small holes which shouldnt need it.

If you wanted to see if just that top section with support will print you could always cut off the bottom 3/4 to say about 5mm below that large overhang. That would allow you to test settings without using too much filament or time.

RE: Poor layers (only some)

Not from just pictures no.

The single best way to debug issues is for you to save your project from Slicer (File>Save As). This will save a .3mf file. The 3mf file contains the model(s), any modifiers you are using and all 3 profiles used to slice it. This allows us to look for problems, slice, check the preview , tweak, reslice etc. We can also export the model and check if it has any issues that may be contributing if needed.

The forum doesn't accept many file types though so you will need to zip up into an archive the 3mf file before you can attach it.

RE: Poor layers (only some)

Thanks for the useful infos, didn´t know that.

There should be attached zip file by now. I suppose my problems do have something to do with layers with full infill, but I cant´t figure which settings are the correct ones

RE: Poor layers (only some)

There are many settings in that project that are sub-optimal for printing in PET. Most of the filament setting for example are from a PLA profile, pet generally only needs 30-50% cooling, running it at 100% is going to make for very weak parts. Also the volumetric limit is too high, again a value normally set for PLA.

Also the support is set to be far far too close, it will be VERY difficult to remove with those settings. One thing I noticed is that you had the solid infill threshold set to 70mm/2 which is causing it to be used around those problem holes. Thats the setting you were looking for, it should be set to 0 to turn it off which is what Ive done. Its sometimes useful for very small cross sections but I wouldnt set it above 5mm/s personally. Now I don't know for sure if that's what your issue is as the pic you showed would lead me to suspect that you have other extrusion issues. Alot of it may be done to the over use of the cooling fan though.

I have attached a modified project file with changes made to how *I* would try printing it (with your choices of infill etc), but I made all the changes to supports and the filament profile I would expect for a petg print. Also I have added a support enforcer and changed the support type for enforcer only. This stops the support being added for the small holes which shouldnt need it.

If you wanted to see if just that top section with support will print you could always cut off the bottom 3/4 to say about 5mm below that large overhang. That would allow you to test settings without using too much filament or time.

RE: Poor layers (only some)

Thanks a lot for your effort, it improved the print a lot.

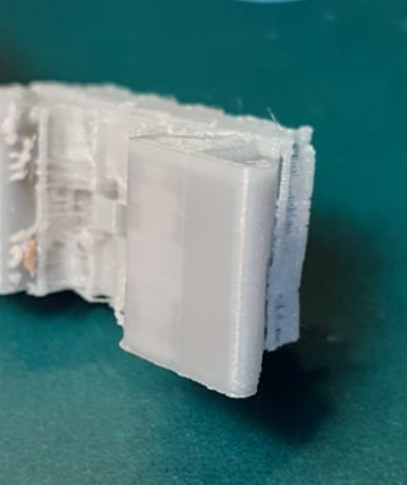

However, i still do have problem with weird shapes. This time they moved "inside", next to the hex hole in the layers with hole, and on the other side of the part the helical shape goes up directly from the wirst layer. The other side seems to be OK

RE: Poor layers (only some)

Its those artefacts that made me say I think you have other printer problems happening, possibly hardware ones or some settings related to your extruder settings as theres nothing in the output from the slicer that would explain them.

I could print that part on my MK3 and it wouldn't have those. I take it your profile is correct for your printer and that you have checked all the usual basic problems like a partial clog on the nozzle, cleaned out the extruder feed gears etc ?