Odd slicing behavior ...

I'm wondering if someone can enlighten me on why I am seeing this odd slicing behavior. Using PrusaSli3r 2.2.0 with a Taz 6.

I'm trying to set the extrusion widths under print settings to 100%, instead of a static extrusion width, however, I'm encounter very different slicing behaviors resulting in less than "nice" print for the 100% setting. The stl model, printer profile, filament setting, and other parameters were identical other than the parameters in the extrusion width. The nozzle diameter under the printer profile was set to 0.5 mm in both cases.

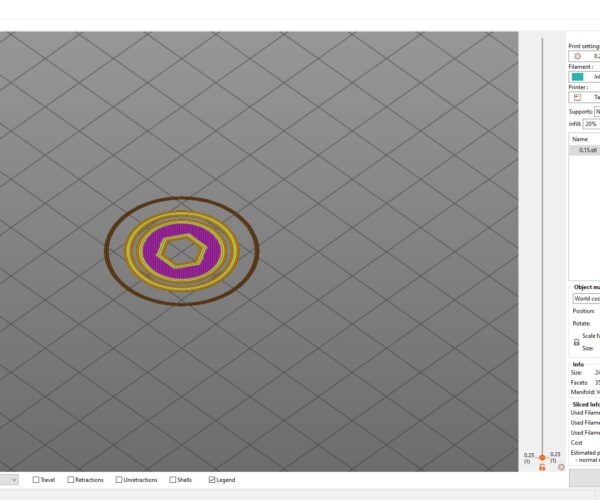

Extrusion width set to 0.5 mm:

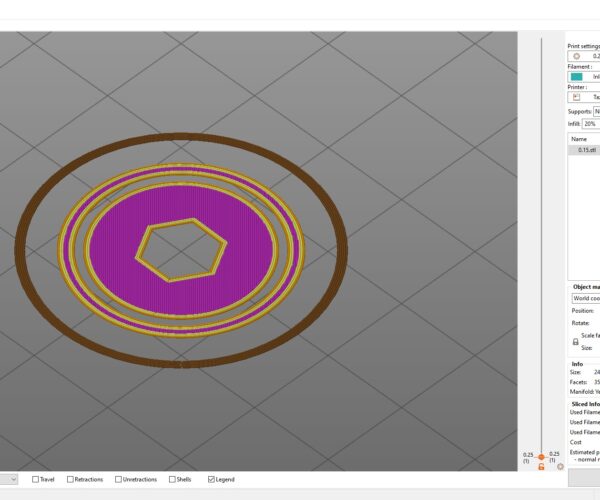

Extrusion width set to 100%:

RE: Odd slicing behavior ...

[...] I'm trying to set the extrusion widths under print settings to 100%, instead of a static extrusion width, however, I'm encounter very different slicing behaviors resulting in less than "nice" print for the 100% setting.

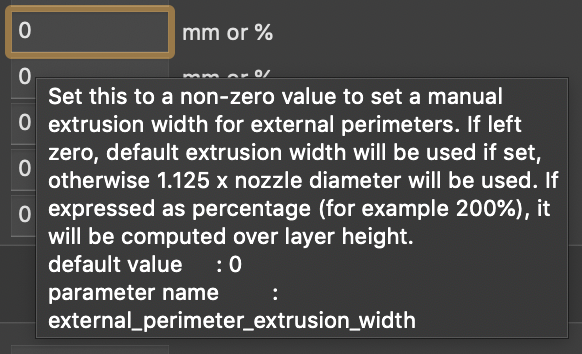

Be aware that PrusaSlicer is based on a fork of the original Slic3r. There were some "interesting" design choices made early on. If you set an extrusion width to a percentage, this is a percentage of the layer height, not nozzle size. If you hover your mouse over the setting box, you can try to read the poorly written help information.

Unfortunately, there's not a lot more documentation out there. To use the same print profile with multiple nozzles, I set extrusion widths to 0 to have PrusaSlicer calculate them at slice time.

Some forks of PrusaSlicer have changes these settings to use percentages of nozzle size, which seems much more intuitive.

I'm sure there were good reasons for doing it the way it was originally implemented in Slic3r, but it's very confusing.

but note that

The stl model, printer profile, filament setting, and other parameters were identical other than the parameters in the extrusion width. The nozzle diameter under the printer profile was set to 0.5 mm in both cases.

Extrusion width set to 0.5 mm:

Extrusion width set to 100%:

RE: Odd slicing behavior ...

Thanks for the quick reply. It is definitely confusing, as it seems intuitively extrusion width would be use the nozzle diameter parameter instead of the layer height parameter.

RE: Odd slicing behavior ...

Thanks for the quick reply. It is definitely confusing, as it seems intuitively extrusion width would be use the nozzle diameter parameter instead of the layer height parameter.

Somewhere out there, there's a Slic3r page describing the approach. I think it made sense at the time where getting good first layer adhesion was a major challenge (pre heated bed days I think). Modern printers have different challenges though, and I agree that being able to link extrusion widths to the current nozzle size is preferable!