Infill modifier creates breaking point

Hi,

i tried to reinforce a part with a 100% infill modifier only on the relevant areas of the print, but the infill generation creates a very weak interface between the area with normal infill and the 100% infill area, which is exactly the opposite of the wanted effect. any ideas?

RE: Infill modifier creates breaking point

Infill doesn't add much to structural strength unless the entire part has a high density - and even then, it's often just resistance to crushing.

You get better mechanical strength with more shells - try increasing the number of perimeters and top/bottom solid layers.

RE: Infill modifier creates breaking point

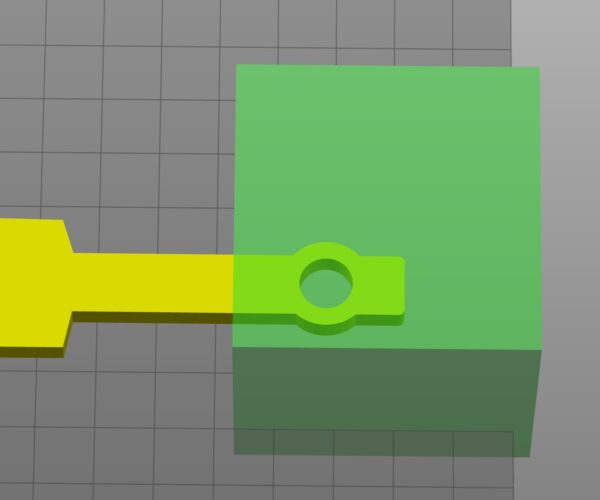

I‘m not sure you understand what i’m trying to say. The part with 15% infill is much stronger than the part with the 100% modifier. The modified part breaks easily at exactly the point where the modifier ends. You can see that in the layer visualisation, that there is a seam which breaks easily

RE: Infill modifier creates breaking point

I‘m not sure you understand what i’m trying to say. The part with 15% infill is much stronger than the part with the 100% modifier. The modified part breaks easily at exactly the point where the modifier ends. You can see that in the layer visualisation, that there is a seam which breaks easily

Try using more external perimeters and wider perimeter extrusion widths. Thicker top & bottom layers will help with the part printed oriented as shown in your top pic. As @vintagepc notes, that will do much more to add strength than varying infill. To compare, print the part with a consistent 15% infill with 2 and 3 perimeters and thicker top/bottom layers and compare the strength of those parts. Don't get hung up on infill adding strength. It isn't really good for that.

As to why it breaks at that point, you can see the seam created where infill changes. Denser infill might help with crushing and some loading, but for overall part strength, perimeters (walls) make the biggest difference.

If you'd care to zip & upload a 3MF project file with your part & settings, more suggestions may be forthcoming.

RE: Infill modifier creates breaking point

@marc-aurel-k

Can you save this sample as 3MF to have a look. I once had a similar problem and found out that it was an issue of the slicer (don't know which version). Using the next releases version and problem was solved. So you can try what happens, when using the Slicer Version 2.2.0 BETA.

Best regards, Clemens

(still waiting for my already shipped MINI)

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)