Increased volumetric flow rate not decreasing print time?

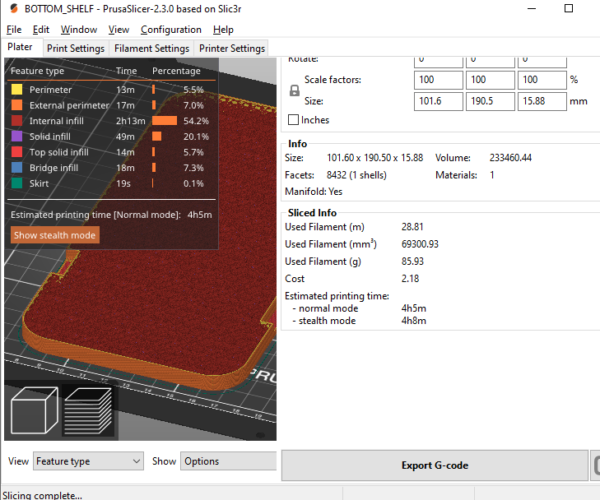

When printing with high speed settings, I've noticed that volumetric flow rate often becomes the limiting factor, especially for internal infill. In this model for example (where I've artificially cranked up the infill % to illustrate the point), internal infill represents 54% of the time.

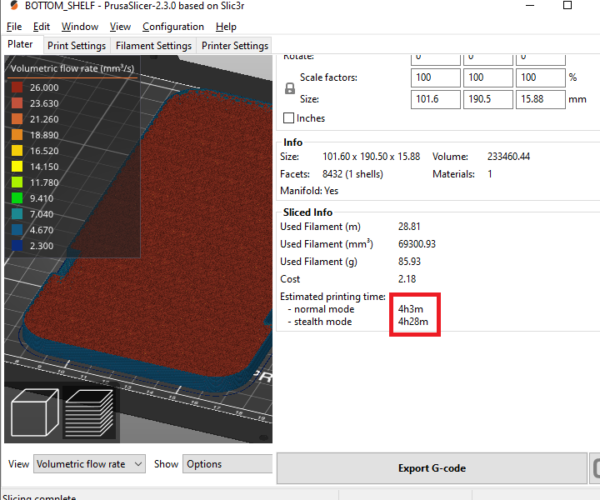

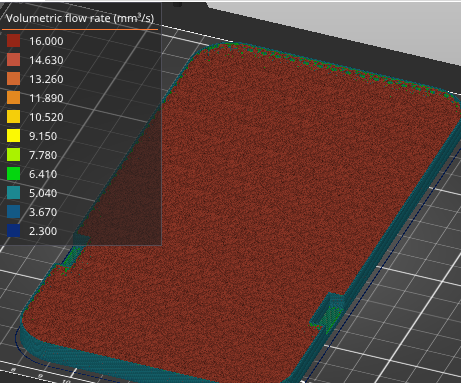

The volumetric flow rate view confirms we are capped on flow rate (which is set to 15 mm3/s - the default for PLA):

So I was wondering whether it would be worth it to do a hot-end upgrade (such as a bimetal heat break) to increase the max flow. I could of course change to a bigger nozzle, but I wanted to see how much speed I could squeeze out of a .4mm nozzle if I could only increase the max flow rate a bit.

So I did an experiment and cranked up the max flow rate in the slicer to 25 mm3/s. The flow rate view confirms we are now extruding plastic faster for the infill (and the print speed is higher). But to my surprise, the estimated print time hardly changed at all! From 4:05 to 4:03. Given that we are now extruding 54% of the model 26/16 mm3/s = 62% faster, I expected a much bigger change.

Can somebody help me understand what's going on here? I have attached the 3MF projected saved from the slicer for easier experimentation.

BOTTOM_SHELF (zipped 3MF)