RE: Huge gaps/low density in support first layer

You cant with Prusa Slicer. That is the base of all supports. If they are coming loose though then that means your bed adhesions and/or your layer one z height are not properly done. A clean bed and correct live z and those little zig zags dont come up.

RE: Huge gaps/low density in support first layer

you could rotate the angle to about 45 so the interface layers have something holding them up.

Shane (AKA FromPrusa)

RE: Huge gaps/low density in support first layer

Shane the original poster is talking about the zig zag back and forth pattern that is placed below all supports peeling up. As such it makes no difference what angle the supports or part is placed at.

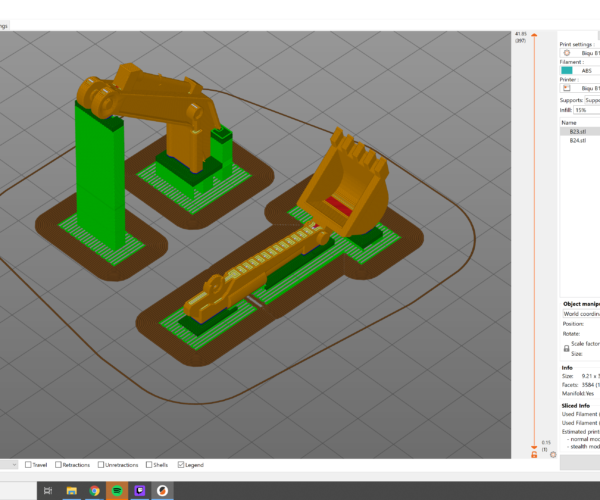

Many Slicers allow you to set that first layer below supports to a solid sheet. This does give better bed adhesion. On a prusa that's correctly tuned though thats not needed as the filament sticks. On a non prusa with a bed surface that's not as good though it means it needs to be scrupulously clean and really well dialled in.

Or you could just install Super Slicer which allows you to configure a solid bottom layer.