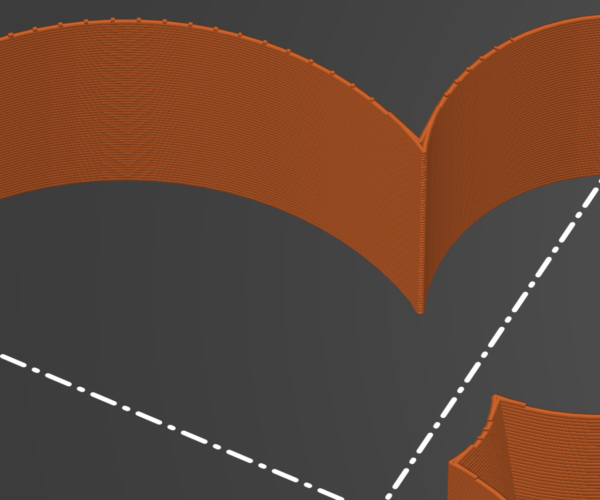

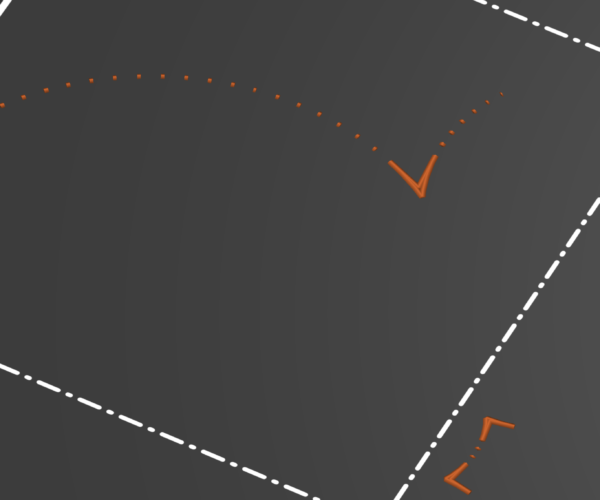

Discontinuous (dotted, dashed) perimeter path on a thin wall

Hello, how to prevent Slicer from creating discontinuous perimeter layer on thin edge?

The last layer separately

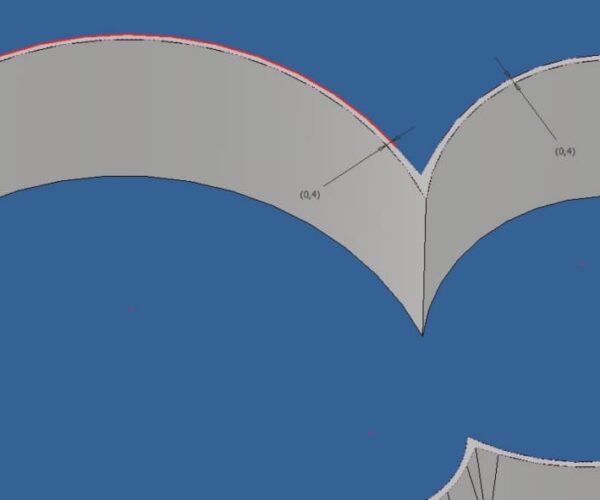

In the original model, there is minimal thickness of this wall same as my nozzle diameter (0,4 mm).

I think it could be caused by STL export when curved shapes with minimal distance same as the nozzle diameter are converted into polylines and when their segments are not parallel, thickness could be lower than the nozzle diameter, so it is rounded to zero by Slicer.

Is possible to force the slicer to print this wall even when it's thinner than a nozzle diameter?

Thank you.

Best Answer by JoanTabb:

Your walls are probably too thin.

try a smaller nozzle,

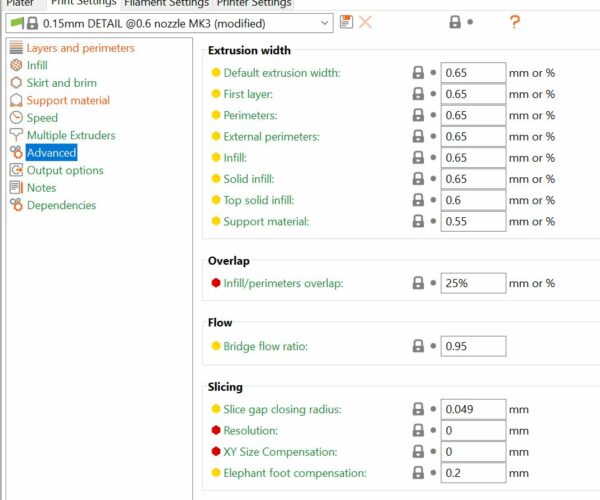

or try adjusting the XY Size Compensation

or remodel the original to have walls thicker than 0.45mm thick

regards Joan

MINI+ owner since 10/2021

RE: Discontinuous (dotted, dashed) perimeter path on a thin wall

Your walls are probably too thin.

try a smaller nozzle,

or try adjusting the XY Size Compensation

or remodel the original to have walls thicker than 0.45mm thick

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Discontinuous (dotted, dashed) perimeter path on a thin wall

I think it could be caused by STL export when curved shapes with minimal distance same as the nozzle diameter are converted into polylines and when their segments are not parallel, thickness could be lower than the nozzle diameter, so it is rounded to zero by Slicer.

This, plus nozzle diameter may not be the same as extrusion width based on your settings.

You can try to turn Detect thin walls on.

RE:

Thanks to all. I didn't realize that a layer thickness is bigger than a nozzle diameter.

With my settings it seems that 0,45mm wall thickness is OK for getting a layer without any discontinuities

(In fact the polylines seems to be perfectly parallel in my exported STL.)

MINI+ owner since 10/2021