RE: Corner printing problem

It would be easiest if you'd save your part & settings in a 3MF project file, zip it up, and attach that file to a reply here. That way we can see the details of the part and the settings you're using. Short of that, I can only suggest:

- Slow down external perimeter speeds.

- Add an extra perimeter or 2.

- Calibrate your extrusion multiplier for that filament (if not done already).

- Calibrate your Linear Advance setting for that filament (if not done already).

RE: Corner printing problem

@bobstro

- slowing down external perimeter would make sense if it would be all over the print?

- this is supposed to print fast, adding 2 layers would make it to thick too

The point is that is only happens where there is only 2 walls nothing else. He is making a weird move in the corners, will upload the file here so you can check it out.

https://drive.google.com/file/d/1Nl4JAdW_9zoXA9OMKSTio-GDly3Cz5cm/view?usp=sharing

I have calibrated the e multiplier, again wouldn't that effect the whole print and not just the middle part?

I honestly don't know how to calibrate linear advance settings, have to read about it and check it.

RE: Corner printing problem

First, some observations:

- You seem to be using a Tronxy printer. I don't know what hotend you have installed, but most printers are shipping with a clone of either the E3D V6 or Volcano hotend. I don't see anything on the Tronxy pages advertising that they're using a high-capacity hotend, so it's a safe bet that it's an E3D V6 clone.

- Every hotend has a maximum rate at which it can melt and move a particular type of filament. This is referred to as the Maximum volumetric speed (MVS) in PrusaSlicer. MVS is calculated as Extrusion Width X Layer Height X Speed and measured in mm^3/s. An E3D V6 hotend with a 0.4mm nozzle can push a bit under 15mm^3/s (11.5mm^3/s is a safe value) of PLA filament through without encountering under extrusion and possible skips and jams. Most clone V6 hotends rate closer to 6.5mm^3/s.

- If you try to move too quickly, under-extrusion can cause inconsistent external surfaces as extrusions may be under-extruded for the long-fast moves on your prints, particularly vertical walls.

- You are trying to print with an extrusion width of 0.44mm, a layer height of 0.2mm, and perimeter speeds of 100mm/s. This equates to 8.8mm^3/s. To stay under 6.5mm^3/s using the same extrusion settings, you need to keep your speeds below ~73mm/s.

- Your machine limits settings are using acceleration rates of 9,000mm/s and jerk rates of 10mm/s. You have checked the option to insert these in your startup gcode, so they will override any settings on the printer. These are probably optimistic. If these are off, it can further throw off the perimeter calculations and affect print quality due to inconsistency with the positioning of successive layers.

- You can increase temperatures to a point (you are using 220C), but that only helps so much. You also seem to be using a carbon-fibre PLA which, if anything, requires printing at a lower MVS (speed).

What is happening is that you are simply printing at speeds that are too high for the filament you are using and your hotend's ability to process it. The deviations you're seeing on the wall are likely caused by:

- Slight but noticeable under-extrusion on the layers without the shelf feature. The solid layers, and the layers where that the bottom curve and top shelf begins print slower due to the extra material and infill. Slowing down allows the hotend to keep up with pushing filament. On layers consisting solely of straight perimeters, the nozzle will move faster. This can result in the bulging at the higher layers.

- Z-seam placement. You have it set to Nearest, which will tuck the seam in a corner but may use different corners for each layer.

You can see the z-seam placement which is roughly corresponding to your defects:

I'd suggest (again):

- Slowing down -- I'd try 40mm/s -- will probably be the quickest thing you can try to confirm this. If slowing down (like WAY down) improves your print, you have your answers.

- Try setting your Z-seam placement (Print Settings->Layers and perimeters->Advanced->Seam position) to Aligned to put all seam all in the same corner for consistency.

- Calibrate your extrusion multiplier. If it is off, your slicer settings won't match your actual printer and filament settings, so you can get variations in extrusion that are particularly visible in vertical walls. There are dozens of guides on this, but here's Prusa's. Measure and average your filament diameter and enter it in your filament profile (Filament settings->Filament->Filament-> Diameter) and calibrate your filament extrusion multiplier and enter that in your filament profile (Filament settings->Filament->Filament-> Extrusion multiplier).

I don't know if your firmware supports Linear Advance. If it does, or if you can upgrade to a version of firmware that does, LA can greatly improve external wall appearance as it compensates for variations in extrusion as nozzle movement speed increases or decreases.

Even with all this, most slicers still have issue getting vertical walls consistent if there are a lot of internal geometry changes. The recommendations for this are the same as I listed above. Cura is working on their new Arachne engine to deal with varying perimeter thickness, but that is still in early Alpha.

All of which is a long way of saying "try slowing it way down and see if quality improves"!

Going fast can only fix so much. Speed is an illusion. If you really want to go faster, try a larger nozzle. You usually have to choose between "fast" and "quality".

RE: Corner printing problem

If you're new here, click the pic to see the whole thing. It's annoying but it works.

Clarification: Slowing down allows the hotend to keep up with pushing filament. On layers consisting solely of straight perimeters, the nozzle will move faster. This can result in the bulging at the higher layers thinner extrusions on the layers without those features.

RE: Corner printing problem

@bobstro

Sorry, I did not mention all the modifications that have been made, since I was assuming its a slicer problem. Yes its a tronxy x5sa with a micro swiss dd hotend/extruder. I have tested the speed up to 120mm/s without extrusion problems. (as far as I can tell, no clicking or missing steps on extrusion) the walls are good its just the corners where there are only walls. The walls itself and the long fast extrusions seem to be really good in my opinion. Even a good bond to previous layer.

Here are some more pictures to show my point:

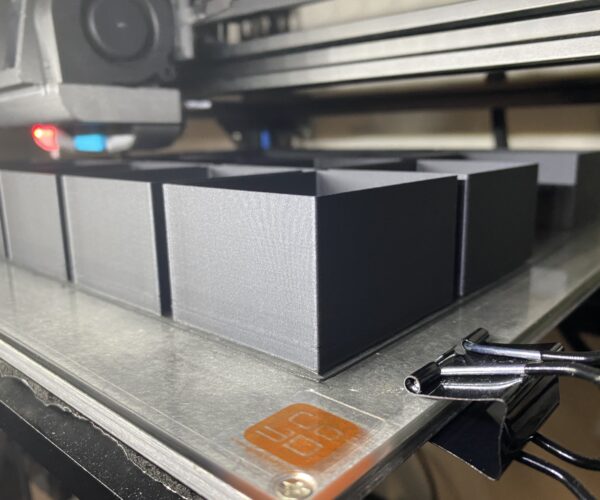

The printer is running now with a batch for another 6-8 hours. Frankly here is a mid print picture of multiple ones. I can not see the same issue?

I can definitely test with significant slower speed. BUT looking at the "speed" preview its all around the same speed. So again will that help? Also I will place the Z seam aligned. That looks to me like it could be the problem.

Yes its a PLA Carbon Fiber I just had laying around to use. 220C is on the first layer, 210C for the rest.

RE: Corner printing problem

As far as the extrusion multiplier goes, it supposed to be 0.88mm and averages at 0.86mm. I know this can be fixed but again is this the problem here? 0.02mm is acceptable for me.

RE: Corner printing problem

The speed preview is only as accurate as your settings. It's good for detecting when a limit is hit, but isn't guaranteed to reflect reality.

All I can suggest is trying the 2 things described above: slow down and move the z-seam.

Slice the parts and spend some time in preview mode examining where layers start and stop. See if changes correspond to defects.

Good luck with it.