Wham Bam

The Wham Bam Flexible Build System sounded so good I ordered one, even though there wasn't one for the Prusa SL1

The SL1 print bed is 130mm x 72mm. I ordered one just a little bigger; The 130mm x 80mm for the Epax X1

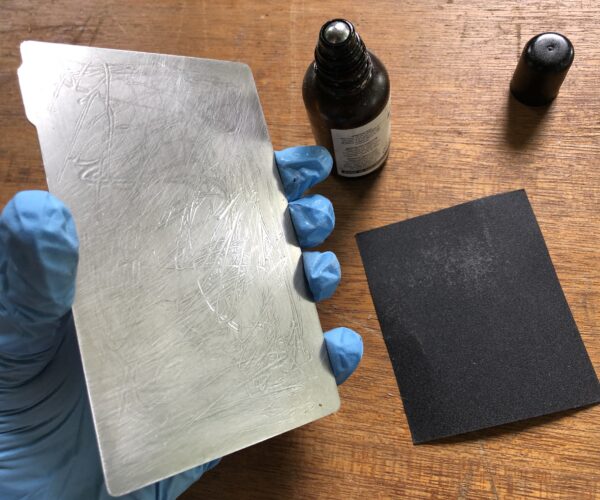

In the middle is the magnet which sticks to the build plate. Removable stainless steel plates are displayed on either side

Before sticking the magnet to the print bed, I trim off the excess. Certainly is going to look better than my print bed which has been scratched again and again

Peel back the protective tape a little so can begin pressing down one end of the sticky side of the 'fridge magnet' on the print bed. Check the instructions which say "It is best practice to allow the 3M bond to cure for 72 hours for maximum adhesion, but 24 hours gets you about 90% of ultimate adhesion." oops. I need to print straight away.. Can't back out now, because if I pull off the end of the 'fridge magnet' which is stuck down, it may never stick properly again.

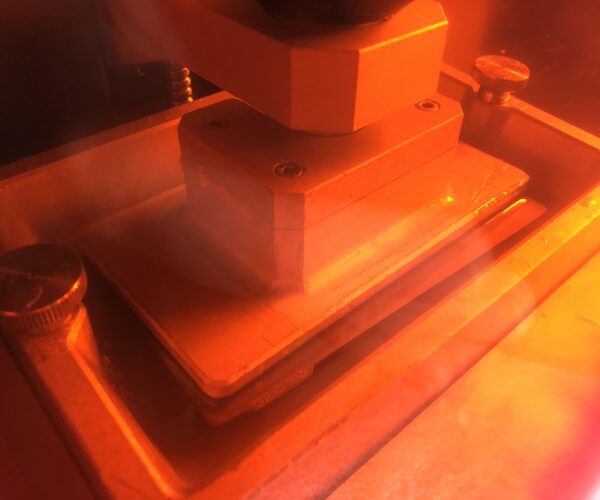

'Fridge magnet' looks good

For my first test, I wipe the surface of a steel plate with a paper towel, but it doesn't remove any (oily?) marks. Oh well...

Calibrated the SL1. Take note that the tab of the steel plate is near the front of the SL1. I verify the steel plate has space between it and the walls of the resin tank. I kick off a print, even though I only stuck the 'fridge magnet' down several minutes earlier. I hope the 'fridge magnet' will stay stuck to the print bed, but I'm not confident. Nor am I confident that the steel plate will remain stuck to the 'fridge magnet', nor even that the print will stick to the steel plate, rather than the FEP. No, I didn't cross my fingers.

The steel plate has slid sideways, probably due to sideways forces applied to it by the resin tank tilting away?

I'm pleased to see the 'fridge magnet' is still stuck to the print bed. I'm also pleased to see that the steel plate is stuck to the 'fridge magnet'. This is such a relief that I'm not too concerned that no print is stuck to the steel plate. I just need to make the steel plate 'stickier'. I fish around in the resin tank and remove the failed print, which is thicker on one side than the other. This means that enough of the print stuck to the steel plate, that it peeled off from the FEP, the part of the print that stuck to the FEP. Later on, it stuck to the FEP better than the steel plate, so it pulled off the steel plate.

After sanding the steel plate with the 400 grit sandpaper that came in the kit, I also applied platebond to make the print stick even better.

Agh. Another failed print. This time the steel plate detached from the 'fridge magnet'. I suspect the reason is that it caught the side of resin tank and became jammed. My apologies for the bad photo. It shows the steel plate still affixed to the print, which is affixed to the FEP.

I decided to turn the steel plate around so the tab is now towards the back of the printer and has less overhang at the front. Recalibrated the printer again.

Well, this is no good. The steel sheet rotated towards the front again, and the print quality was so bad I aborted the print

I'd forgotten to apply Platebond, so this proved that sanding the steel plate with 400 grit sandpaper is sufficient for the print to stick to the steel plate. In order to stop the steel plate from moving during printing I decided to fold one site at right angles. Its fortunate I'd purchased a steel plate that was 8mm too wide.

Bending the steel plate in my press.

Unfortunately, the bend is so close to the edge of the steel plate, and this steel plate is so thin, the best is can do is a 45 degree bend. This should be enough.

Another couple of hours of printing time to find out the result. This time I'm crossing my fingers. Both hands!

RE: Wham Bam

Wam Bam makes good products. I hope you have great success. I would guess you lose Z height with this mod.

--------------------

Chuck H

3D Printer Review Blog

RE: Wham Bam

Lost 2.6mm in Z height, but this was easily accommodated with by re-calibration.

That last print failed, with several mm of print before the steel plate popped off the print bed. I took the steel plate off to the vice and attempted to bend it to 90 degrees. It was so springy that I ended resorting to hammer it like a blacksmith. Now with the bend closer to 70 degrees I tried again.

Much better print quality this time, and the steel plate isn't rotating, however after 20mm of printing the steel plate popped off the print bed again.

The end nearest my bend is narrower. Does this mean the steel plate is slowly pulling away from the print bed? Perhaps a 90 degree bend would make all the difference. On the other hand, the fridge magnet isn't strong enough to stop the steel plate popping off. It looks like the additional weight of my print is too much? Also, the sides aren't vertical, which suggests the steel plate slowly shifts sideways for the first part of the print.

I don't know, but I've run out of time. I've removed the 'fridge magnet' which peeled off rather easily with the help of a putty knife, and have gone back to the normal print bed. I must say, the very last print popped off easily by bending the flexible steel plate, so I am disappointed it doesn't work as expected. I'll ask Wham Bam Systems to comment.

RE: Wham Bam

The flexible build plates for resin printers are not recommended for printers with a tilting vat. The tilting peeling action. which makes peeling prints off of the FEP easier, works at making the steel spring steel plate easier to peel off the magnet.

RE: Wham Bam

@michael-19

Since the platform is used to complete the circuit for testing the resin level, did having the plate and magnet installed have any impact on that feature?

RE: Wham Bam

@wargaming-terrain-factory

Do you have a link to that recommendation?

--------------------

Chuck H

3D Printer Review Blog

RE: Wham Bam

@wargaming-terrain-factory

I wonder if you could FDM print platform with stronger magnets embedded that would better hold the plate. You could even adjust the overall height to account for the steel sheet so that no Z height was lost.

Of course per my question to Michael, a plastic platform would definitely kill the resin level sensor functionality.

RE: Wham Bam

@wargaming-terrain-factory

Do you have a link to that recommendation?

https://whambamsystems.com/fbs-for-resin

It's in the "Don't See Your Printer Listed?" section:

Some of our current sizes may fit other printers not listed, to verify please measure your build plate (do not rely on build volume) before ordering. Not recommended for printers with tilting vats. Wham Bam will not be responsible for mistaken sizes ordered.