MMU/TPU settings?

Hey everyone! I more or less can print in my harder TPU's (~95a shore).... But I get a lot of strings, so I have to rescue the print once a millimeter or so.

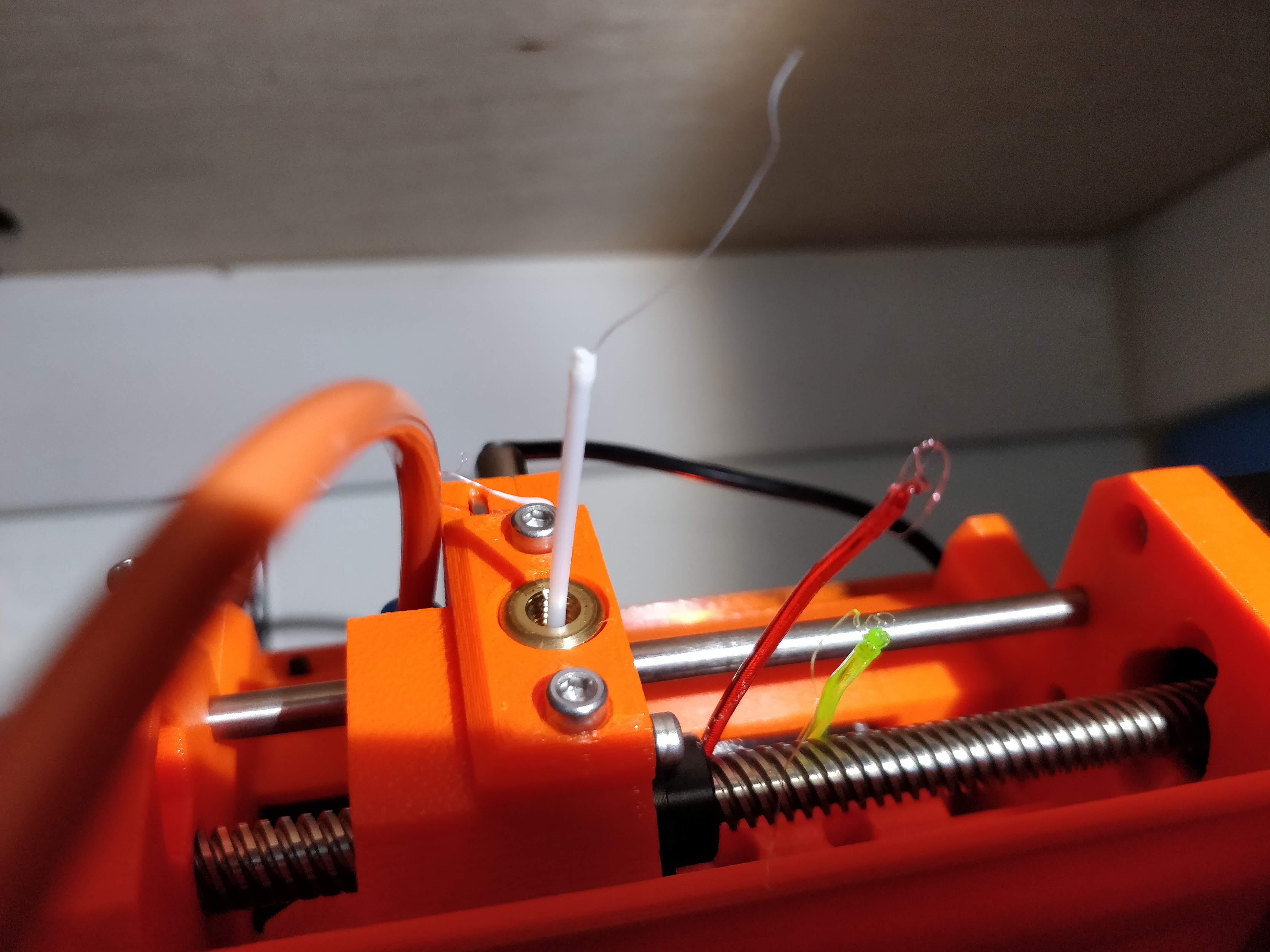

I'm getting fine long strings

which seem close to being right, but clearly aren't.

The white stuff is a bit harder than the other two, but I'm using 75/85/100 "unloading speed at the start", otherwise all settings are the same:

I'm very open on suggestions here. I have another print with the unloading speeds swapped, but I want to get a feeling for how much this fails. I suspect I shouldn't be counting failures but merely judging based on the shapes of the tips.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: MMU/TPU settings?

There are other issues with TPU:

Related to this topic, I'm having issues with kinky TPU's sometimes winding about the MMY hobbed gear instead of feeding back into the PTFE inlet tubes for the MMU. Lightening the tension (already screwheads showing) may have helped a bit, but I wonder if the accelerations and speed should/could be turned down for TPU.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: MMU/TPU settings?

Another issue: Calibrating the tube length depends on what you're feeding. I can get PLA or PETg to feed and always end up within 1-2 mm on the hobbed gear, but feeding TPU will fall well short (not visible, about 1.5cm short).

I feel that when the printer is printing with a TPU, and knows it, it compensates? I certainly was BARELY getting anything out of the printer, the entire purge was extruding air, then it would pick up as I got to the object.

What I'm wondering is if I need to recalibrate all 5 channels every time I change filament material.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: MMU/TPU settings?

The problems you are describing seems to be due to a design flaw of the whole mmu 2 unit.

Because you can not set the tension of the gears for every filament but instead you have to set it for all filaments. Which is obviously a big problem if you want to print with flexible filaments.

The new firmware with per gear calibration should help though but I still don't like it because I was planing to print a lot with flexibles with the mmu 2 🙁

Re: MMU/TPU settings?

The problems you are describing seems to be due to a design flaw of the whole mmu 2 unit.

Because you can not set the tension of the gears for every filament but instead you have to set it for all filaments. Which is obviously a big problem if you want to print with flexible filaments.

The new firmware with per gear calibration should help though but I still don't like it because I was planing to print a lot with flexibles with the mmu 2 🙁

You can currently already calibrate per gear/filament on the current firmware using the 'secret menu' options.

The first thing you mentioned would not be a firmware thing, but rather a hardware redesign....

Re: MMU/TPU settings?

I believe he is referring to the spring tension - all of the channels share a common shaft.

You could run smaller gears on the TPU channels for lower tension. In reality, the slicer already sends information about which type of filament is loaded into the machine - I do not know if that is taken into account when loading and unloading.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: MMU/TPU settings?

For the people not using the included filament holders - have you tried shortening the feeding Bowden tubes?

I have found that some of my issues with unloading filament and having it bunch up around the gears could be in part to the high force it can take to shove flexibles (especially kinky ones) back up the tube. My filament box is as good as ejecting into free space, but shoving that much filament down the tube can be problematic.

I will try running all of these at as short a distance as practical, maybe a few inches.

I would like to know if anyone else has experience here.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: MMU/TPU settings?

I have tried with TPC flex from formfutura with success. Here below you can get some tips that might help you to print with MMU 2.0 and maybe not only with flex filaments.

1) I have drilled all filament spool holders with 2.5 mm drill. ( all the holes where passes a filament, please look at the movies below). It works much smoother with minimal friction. I did not cut the browden tubes.

2) Align all your filaments with the gears on MMU 2.0 as well as the extruder gear, cut correctly filaments.

3) Set correctly the F.I.N.D.A sensor. I mean the height. It cannot be too close. I think it is shows in the movies below.

4) In order to even more minimalize the friction caused by spool holders I printed, in addition, wheels that are fixed on the rod of the spool holder. It is the wheel with 8 mm diameter of the hole to pass the rod (if I am not mistaken) and external 25 mm diameter. For one spool holder I printed 4. So far it works. If somebody is interested in I can post it somewhere.

5) I download the newest firmware 1.01 for MMU 2.0 and I set/calibrated correctly all gears.

6) I set correctly the screws tension of the extruder gear. I did it in this way. I preheated the nozzle for the filament I wanted to use. I unscrewed completely the screws from the gear box. Then I started the load filament procedure and I started to screw the screws from the extruder gear as long as long it started to take the filament. I screwed half or one turn more and I tested it. For me it works perfectly.

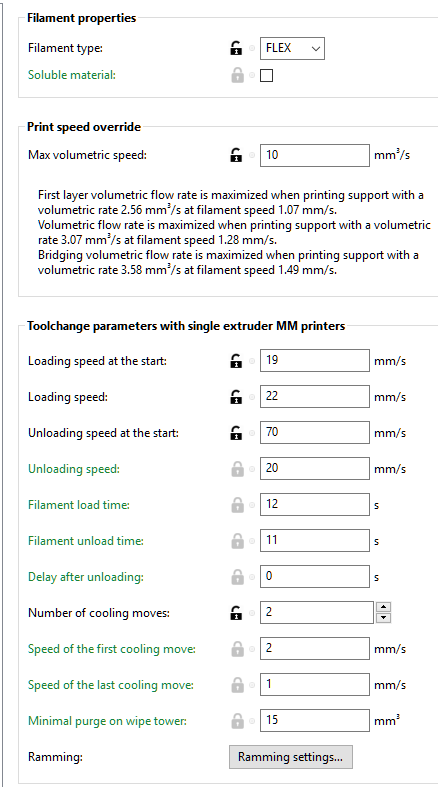

7) To set the ramming and slic3r I recommend to have a look at this videos:

You should find interesting tips. So far it is working. I will try now with Atlas support PVA. I hope it will work as well...I hope it helps somebody a bit.

Re: MMU/TPU settings?

Agreed. Most of my issues came from the filament feeds, once I got those figured out it's been MUCH better. I scrapped the entire Prusa set up and have never looked back.

I'm reconsidering the single-bowden tube - the smaller diameter of the interstitial piece I think is there to form the tip, so you want a smaller neck before the looser bowden tube.

I already have the firmware, and I'm a little unsure how much more to back off the screws. With nothing in the MMU, do your screwheads show? I keep them even with the top in that state (0.6mm for my washer I have in there)

OMG that is an hour long! I am interested in improving my tips.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.