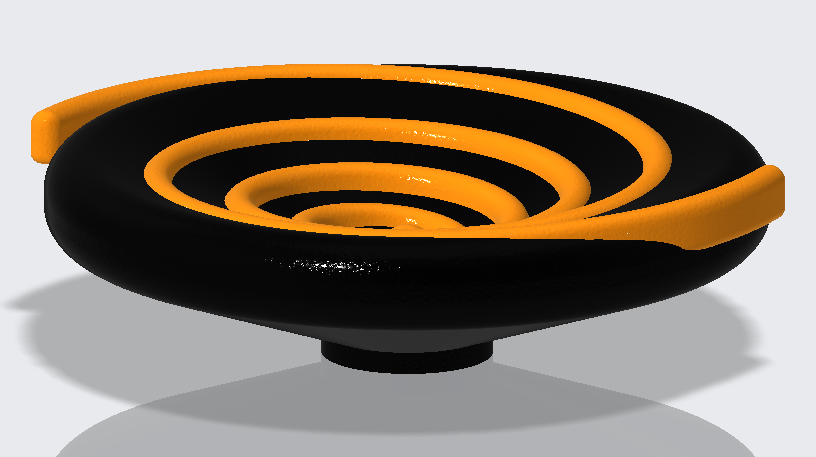

Extrusion Indicator feasibility

This is my 4th version already, so it may be version 15 by the time my kit arrives (another 2 or 3 weeks allegedly). At this point, I'm still a printing virgin. What's a good-easy technique/software platform to use for splitting this small, simple part into two colors as shown in the picture? The part is small (36.2mm OD).

RE: Extrusion Indicator feasibility

this model will have problems printing, because of the back shape.

it will need supports... for a first print I would make the back flat,

and use a thick Magnet

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Extrusion Indicator feasibility

@joantabb

I'm hesitant to flatten the back as that will add weight. Couldn't hurt to try it though. I suppose that's the beauty when you can just print a new one. I wouldn't care if there are support blemishes though, it's a non-cosmetic surface.

I'd like to print the orange in a shiny or shimmery finish and the black in a matte finish. Would/could/should I use a mix of material? Of course I'll start with what I've got. I've already ordered or received the jet black petg (prusa), black pla 2.5 kg (ic3d-amazon), black abs (flashforge-walmart). Plus, the Prusament PETG Orange and more but that's the only orange I've ordered. I'm open to suggestions.