Absolute waste of money

After meticulously completing the assembly of the MMU2, I've spent the past day and a half trying unsuccessfully to get a first layer calibration and spending huge amounts of time attending to the MMU which requires my attention constantly.

RE: Absolute waste of money

I had the MMU1 which was a pain, and then I've got the MMU2 at a discount price because MMU1 was so unreliable. I have it since April 2019 now and maybe I've been able to had one successful print. Did not use it for almost a year, I have been only using Single mode and even there it was a pain. Now I had to print a lot of COVID face shield and I had so many failed load or spool join that I decided to have a look at it and the main thing that you have to adjust correctly is the IR sensor.

I cannot say that I was successful in adjusting it so far, because when it is working, it can stop working again after a day, probably the way it is attached to the extruder is poorly designed and after a while, with the tension from the PTFE tube from the MMU, it get moved a bit but if you manage to adjust this IR sensor properly, I'm quite sure you will be happy with this.

RE: Absolute waste of money

It took me three solid days before I could get the MMU to print a z calibration reliably.

Yesterday, I printed two from each of the 5 filaments.

Today, I can't get it load and unload filament.

I've cleared problems in the MMU and still get error messages on the LCD panel.

The unit is completely inconsistent and unreliable.

RE: Absolute waste of money

I found the need to look at the LCD sensor menu to see the filament sensor status a pain in the rump...

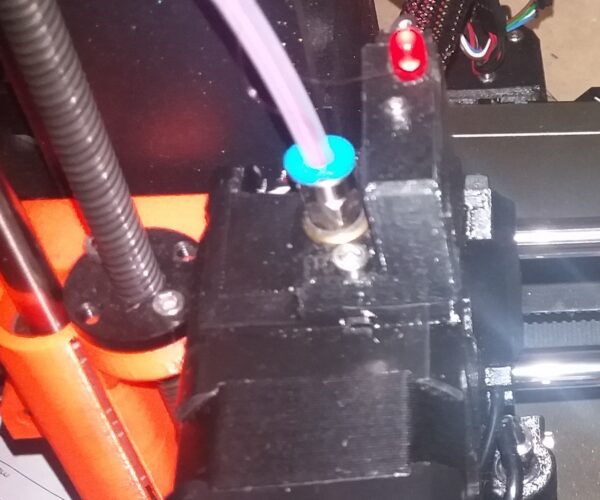

so I fitted a 5volt LED to give immediate confirmation of status.

now you can see the effects of your adjustments immediately!

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Absolute waste of money

The unit is, in my not so humble opinion, a piece of shit.

Every solution that I've read about that has worked, has involved a user modification.

That's not what I spent the $300 on.

Modifications should improve the performance of the unit not be required to make it functional.

RE: Absolute waste of money

@bobhouse1

If you need some help from the community, feel free to describe your issues in detail. The current MMU2 is discussed and described in so many threads. It's well known to be not easy to setup and operate. But in many cases it's doable without any modifications.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Absolute waste of money

As I already posted, yesterday I was able to get MK3 and MMU2 to print z calibrations.

Twice with each filament. No problems.

Today, I tried running the gcode for the sheep. A 2 color print. 2 hours and 40 minutes.

8 minutes in, it had an unload error. I cleared it manually and but LCD insisted that there was still a problem.

It has since gotten to a point where I can't even load filament as the idlers won't engage the pulley gears. That holds true for the "Load All" command as well as trying to load them one at a time.

And I appreciate the offer of help, but as I await replies, I continue to tinker with the printer solving one problem and another comes up.

RE: Absolute waste of money

Hi,

I had similar problems, the cause, how unlikely it sounds, a wobbly idler barrel assembly. I print, change filaments, load / unload since then and have only sporadic problems. The wobble was barely perceptible but changed the electronics where the MMU establishes its home position. The bearings line up with the gears when they're supposed to now.

The tensioners are loose, with exact alignment the tensioners aren't as tight. Without changing anything I loaded TPU filament yesterday and did a pair of masks loaded and unloaded without any problem whatsoever. No change at all on the tension screws.

I did have to add another tie-wrap to the FINDA cable reducing the movement, printed the updated selector, and I keep it clean. Before I located the error I tried improving the alimentation traction by the five festo entry.

I'm convinced that the errors that many are having relate more to a defective part in the alimentation to the selector and not software. With perfectly aligned flow the unit has little problems.

Good luck and be safe,

Phil

Stay safe and healthy, Phil

RE: Absolute waste of money

Hi,

I read about the problems with the MMU when I ordered it. That didn't dissuade me since I also viewed other posts where the unit ran for days with thousands of tool changes. So I took the challenge and have improved my unit to be much more reliable. The price one pays for a Prusa product comes with a support team unmatched IMHO.

Having a Prusa printer is having a dependable printer. My previous experience with a 3d printer was terrible, support took up to a week to get back with me, they always made any failure to be my fault. There are too many good points with Prusa's products making them leaders.

Calibration of this machine helps me to print precise parts. Filament flow rate is crucial to getting accurate parts. Keep one's firmware and software current as each iteration makes for better accuracy and dependability.

Finally, an important point is that with FDM's process it allows for parts which could never be made by injection to be produced.

Stay safe and healthy, Phil

RE: Absolute waste of money

I will agree with everyone that the MMU2s is not a consumer level product and for the price it takes too much tinkering to get working for the average consumer. I also think that it is kind of dissapointing that not more development is put into the firmware and slicer side of things. I think that the product, even as it is works. But it requires a lot of thought and consideration, testing etc in the build, especially for things such as friction.

It also has a learning curve that is rather steep and some less considerate implementations.

My tip to everyone that can't get this thing to work is to firstly, DONT OVERTIGHTEN STUFF!. Don't excessively tighten PTFE tube holders, just enough to hold the thing in place while printing. Don't over tighten idlers in the MMU or the extruder. Having too tight idlers WILL cause jams, I suggest going for what the build manual suggests.

Finally: If you are at a place where you haven't got a single print working yet and you print with something other than high quality, smooth surfaced PLA. I suggest you keep to PLA till you got it working and have build up experience with the printer.

I kind of think that Prusa as a company owes the unsatishfied part of their userbase a new revision of the machine. Even just a revision of the printed parts with some of the community upgrades (like actual PTFE plugs everywhere) would help immensely. But I also really think that the software (slicer) and firmware needs a revision. As it is now you should really try to avoid using the LCD and MMU button interface for filament changes, as anything other than the ideal filament qualities will cause jams (ie. if you try to use the printer interface for filament unload with PETG or other stringy material).

But to everyone who think it doesn't work, it does. It works exactly as advertised, I have been running it all week with only minor problems and rookie mistakes. And that was on a brand new kit build of an MK3 that had never been tested prior to running with the MMU2s.

RE: Absolute waste of money

@ejth

I will agree that it does work after some mods. But I think think the big thing for me was that the printer without the MMU worked so well. And you sort of come into the MMU2S with the same expectation. There are some definitely design flaws. I wouldn't even think about trying TPU in this thing. I've finally got PLA, PETG, PVA+ and BVOH working in this thing, but based on having watched this thing for many many hours now, I can't imagine trying to throw something like TPU into the mix.

I REALLY hope that prusa is taking some of the feedback to heart and trying to improve the thing. Out of the box it's really a nightmare. it's only after I added 3 or 4 mods did it kind of work. I don't have the confidence in it I do as the stand-alone single filament MK3S+. I have two MK3S+ units. I only upgraded one to MMU2S. I don't plan on upgrading the other. I'm keeping my eye on the Palette V3 Pro. If I do decide to go multi-material for the other printer I might take a chance on that.

Again, the MK3S+ is awesome. And I still recommend to any of my friends getting a 3d printer to get a prusa. I'm pretty sure, at this point, I couldn't put the same strong recommendation behind the MMU2S. It's just to finicky at this point.

RE: Absolute waste of money

I've been printing with the mmu2s TPU without any problems. That said I've not done more than single material. TPU's only profile is for single mode.

Stay safe and healthy, Phil

RE: Absolute waste of money

@pcweber

yeah well, I could see single mode working. That's one load to the extruder and one unload at the end. But the constant yanking of the filament from the extruder.... and having to dork with the idler tension etc, I'm not sure I'm ready for that inevitable frustration. That and the likely blobby tips which might work on being pulled from the extruder but I could see being a problem the next time a tool change asks for that filament and it has to push tpu down the bowden tube with a blobby tip.

Let's not even mention switching between materials like TPU->Soluble(PVA/BVOH/etc)-> and back again.

TPU isn't even officially supported according to the manual, they are working on it...

I'm patient, but I'm not sure I'm that patient... I'm just happy that I can have a print with PLA or PETG run overnight and not have some sort of MMU issue waiting for me in the morning. I have the second non-mmu MK3S+ for doing tpu stuff.