Re: Testing Print Surfaces

My wife is understanding but she puts her foot down on them coming on vacation with us. There are somethings I cannot talker into.

Besides, can you imagine that discussion with TSA? It’s a 3D printer. Sure sir, put you hands up and spread em. Your are gettin a cavity search. I might be the highlight of the trip.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

I understand It is a SWMBO conflict... you are not alone 😀

Re: Testing Print Surfaces

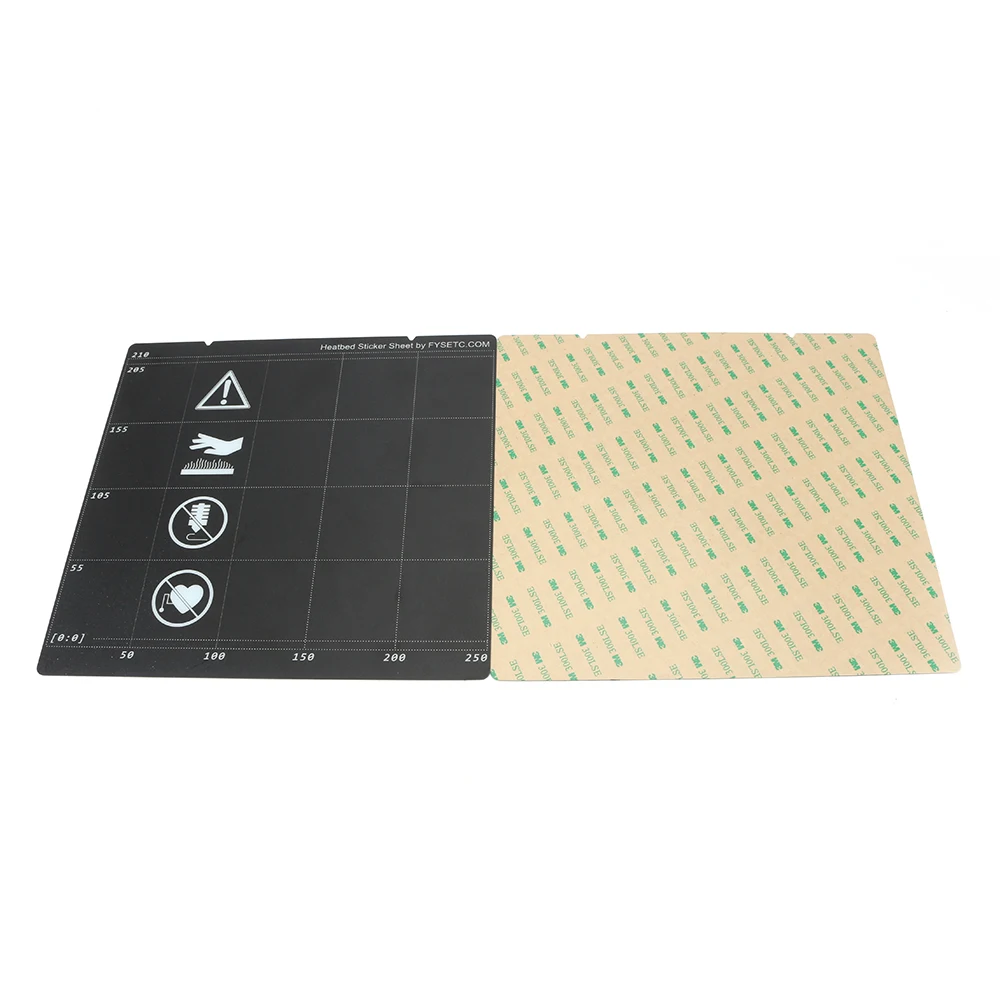

Just been using one of these build sheets from FYSETC. Things really stick to it even without cleaning the surface.

Here is my review of that surface.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

[...] Here is my review of that surface.

Link?

Re: Testing Print Surfaces

I tried to post the link. Here is another attempt - https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f61/review-cheap-mk52-print-surface-t26801.html#p122116

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

5/5 stars for my 3rd party, Thekkiinngg textured PEI plate for printing PETG. It's been giving me more reliable adhesion and easier parts removal than the stock Prusa flat PEI plate. However, if you try it straight out of the package, you'll wonder why you bought it because nothing sticks.

You must initially condition the surface to bring out its good adhesion behavior. Wash with Dawn then do three cycles of Windex and IPA cleaning with your bed at printing temp to condition the surface. Finish with IPA, you do NOT need Windex residue to ease parts removal. Once conditioning is completed, adjust your live-Z. It will probably be 0.100 to 0.200 lower than for the smooth PRUSA sheet.

Textured finish looks great, but is slightly more sparse than the (impossible to get) Prusa textured sheet.

This has become the sheet I use for 95%+ of my prints. Nearly all my prints are in PETG. PLA also works on the sheet, but adhesion is not quite as firm as with PETG.

I only wipe the sheet down with IPA after 3/4 print jobs. Most of the time, I can remove the parts and not wipe down the plate if I only touched the plate with my fingernails (less oil transfer).

PETG behavior is reliable and consistent. I simply don't have to worry about my PETG 1st layers sticking correctly nor tall, thin objects toppling over. Parts come off so easily I can have ask wife to clear the plate when I'm away.

Thekkiinngg Prusa i3 MK3 Mk2.5 Double-Sided Pei Textured Powder-Coated Spring Steel Sheet V3 Version 3

Currently its about $64 with shipping from Amazon.

Re: Testing Print Surfaces

5/5 stars for my 3rd party, Thekkiinngg textured PEI plate for printing PETG. It's been giving me more reliable adhesion and easier parts removal than the stock Prusa flat PEI plate. However, if you try it straight out of the package, you'll wonder why you bought it because nothing sticks.

You must initially condition the surface to bring out its good adhesion behavior. Wash with Dawn then do three cycles of Windex and IPA cleaning with your bed at printing temp to condition the surface. Finish with IPA, you do NOT need Windex residue to ease parts removal. Once conditioning is completed, adjust your live-Z. It will probably be 0.100 to 0.200 lower than for the smooth PRUSA sheet.

Textured finish looks great, but is slightly more sparse than the (impossible to get) Prusa textured sheet.

This has become the sheet I use for 95%+ of my prints. Nearly all my prints are in PETG. PLA also works on the sheet, but adhesion is not quite as firm as with PETG.

I only wipe the sheet down with IPA after 3/4 print jobs. Most of the time, I can remove the parts and not wipe down the plate if I only touched the plate with my fingernails (less oil transfer).

PETG behavior is reliable and consistent. I simply don't have to worry about my PETG 1st layers sticking correctly nor tall, thin objects toppling over. Parts come off so easily I can have ask wife to clear the plate when I'm away.

Thekkiinngg Prusa i3 MK3 Mk2.5 Double-Sided Pei Textured Powder-Coated Spring Steel Sheet V3 Version 3

Currently its about $64 with shipping from Amazon.

thekkiinngg textured plate.jpg

Found it cheaper on eBay

--------------------

Chuck H

3D Printer Review Blog

RE: Testing Print Surfaces

Why Dawn specifically? Does it matter?

I have this sheet (V4) and it made a few good prints, but now is refusing to hold anything. Got through two of the Save Pangolins with no trouble. Tried printing the LFS elephant like 10 times now and always loses a piece along the way. Freaking maddening.

RE: Testing Print Surfaces

think dawn is good because it doesn't have the fancy stuff...safe enough for the wildlife...safe enough for my sheet.

I have a Prusa,therefore I research.

RE: Testing Print Surfaces

Why Dawn specifically? Does it matter?

I have this sheet (V4) and it made a few good prints, but now is refusing to hold anything. Got through two of the Save Pangolins with no trouble. Tried printing the LFS elephant like 10 times now and always loses a piece along the way. Freaking maddening.

Lost pieces of the print or the Print bed surface?

I have found that PETG can stick too much especially if you let bed cool too much.

--------------------

Chuck H

3D Printer Review Blog

RE: Testing Print Surfaces

Using PLA. Some of the pieces curling off the sheet and then causing a collision with the nozzle.

RE: Testing Print Surfaces

Soap and plenty of water to rinse is all you need. I do use IPA also.

--------------------

Chuck H

3D Printer Review Blog

RE: Testing Print Surfaces

Why Dawn specifically? Does it matter?

I have this sheet (V4) and it made a few good prints, but now is refusing to hold anything. Got through two of the Save Pangolins with no trouble. Tried printing the LFS elephant like 10 times now and always loses a piece along the way. Freaking maddening.

The magic is original formula Dawn without vinegar, hand softeners or other fancy additives. Other brands will work, of course, and Dawn itself is sold by other names (e.g. Fairy in UK), but Dawn is something that can be recommended and is widely available. If your can't find it, try something similar (no additives, etc.) that you can.

-

A dirty PEI print surface. Even if you don't think this is the cause, it's always a good idea to make sure your PEI surface is clean before trying any other fixes. Take it to the kitchen sink and give it a good dunk with Dawn (original formula, no vinegar or hand softener variants) dishwashing soap or your local equivalent (e.g. Fairy in UK). Use a clean paper towel to clean it off, and another to dry it. Avoid using any sponge or cloth that has been in contact with grease. Above all else, avoid touching the PEI print surface. Once it's good and clean, you should be able to use 91%+ isopropyl alcohol between prints, 100% acetone when that fails, and another dunk when acetone fails. Worst-case, use a 3M 7445 ScotchBrite pad or equivalent to give it a very light buff, but only infrequently.

-

If you have not already done so, try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the on-board routine. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When it's right, you should be able to gently rub it without it coming loose. Then start lowering (more negative) the level until there are no gaps between layers. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines without dislodging them.

RE: Testing Print Surfaces

Thanks. Washed the plate quite thoroughly with dish soap. I don't have dawn, but our soap is an ammonia free, no additive option as well.

Followed with a strong dose of IPA.

Printed the 75x75 square which adhered and looked decent (to my rookie eye).

Then printed the LFS elephant and it finished with no issues.

RE: Testing Print Surfaces

This thread has great information! Thanks for sharing!

My experience is that the Prusa PEI sheet is too adhesive for PETG printing (I do mostly PETG) and the surface is damaged over time

The Prusa powder coat is never in stock so I have given up trying to buy one

The ebay powder coat (same as the OP) works perfectly for me with PETG. Parts are much easier to remove than the Prusa PEI sheet and I have done loads of prints and the surface is is good condition, better than expected for a Chinese ebay purchase

RE: Testing Print Surfaces

[...] The Prusa powder coat is never in stock so I have given up trying to buy one

They were available for several hours today, and at least briefly for each of the last few days. You just have to check a few times daily.

RE: Testing Print Surfaces

I ordered last week. Still waitlisted.

--------------------

Chuck H

3D Printer Review Blog

RE: Testing Print Surfaces

I ordered last week. Still waitlisted.

There's a waitlist, or are you still waiting one from a 2018 order? I think it's just hit-or-miss for e-store stock.

RE: Testing Print Surfaces

I ordered last week. Still waitlisted.

There's a waitlist, or are you still waiting one from a 2018 order? I think it's just hit-or-miss for e-store stock.

I should clarify. My order for bed sheet from last week is waitlisted.

--------------------

Chuck H

3D Printer Review Blog