Printer enclosure challenges and how i tackled them

I built my mk3s+ kit on my livingroom coffee table. After assembly I did the first test prints there and it was silent and sweet. Needless to say, the coffee able is made of heavy marble.

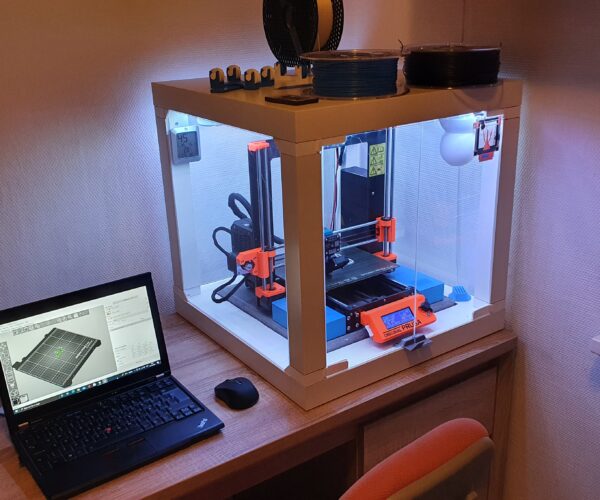

I got me an IKEA Lack enclosure and all of a sudden I was getting all kinds of resonance noise from the boards which I learnt are hollowed.

Secondly if I did nnotleave the doors open during long prints, my enclosure temperature started rising. Leaving the door open kind of defeated the idea with a noise damping enclosure and the risk of more dust getting in.

After much Internet searching and experimenting with different solutions, I finally came to my current setup which I would like to share incase someone someday is in the same boat.

I tried printing different noise damping standoff but none could compare with my coffee table.

I was not very excited to use the suggested 50x50cm concete paving slab as I felt it was too big and its rough surface stuck out like a sore thumb. I finally gave in to the temptation After I realised that the slab did not have to be that big, so I bought a 40x40x5cm one which just matches the mk3s footprint with minimal unsightly side shelving.

I went further to hide it a bit better by countersinking it into the base and if not for the foam insulation under it, it would have completely disappeared into the base. Anyway it is much better that placing the rough slab on top.

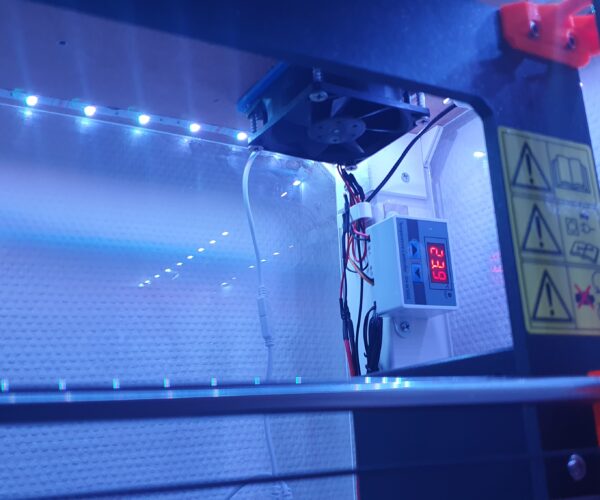

As regards the heating, I printed a fan duct and cowl, I mounted a 80mmx 80mm old PC fan and a temperature controller which starts the exhaust fan . I have set it so the temps in the enclosure does not exceed 30 degrees centigrade and it does a good job keeping it below that. When I have just one of the doors open, the fan never needs to turn on as the temp never climbs above that.

For good measure I mounted a an extra thermometer and hygrometer with memory so it always saves the highest and lowest recorded values if I am not there.

I mounted a stand alone wifi cam that runs on my house network for remote monitoring.

Not to forget a RGB led and a wifi mains switch so I can cut out the power remotely if a print I finished.

Here are a few pics.

That's one way

I don't use an enclosure to dampen noise - so our applications are different. As you and I both discovered, the enclosure makes it noisier not quieter. I also don't try to print PLA nor PETG in an enclosure - these are not high temp filaments and the enclosure adds cooling challenges. I use an enclosure to print high temp filaments so I can vent the toxic elements outside through a ventilation system. Blowing the fan right into the room would defeat the purpose of the enclosure - containing environment for high temp filaments that need a hot chamber to be printed without warping. But very creative - I would have just recommended squash balls under the enclosure and under the printer - by bye resonance. I leave my enclosure door open for low temp prints, and run my vent system low to just create a negative pressure to pull in cool air and vent aerosols from PLA and PETG that the nozzle creates. (see the fine dust that accumulates on your enclosure windows? That's the bad stuff. I'd recommend not blowing from the enclosure out into your house - you will poison your family.