Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

@ButterworthDesign

Did u put as much attention to N4 as u did to N4A? I just printed N4 accourding the instructions and it took me quite some grinding to make the heatsink fit and the PFTE tube does not fit in by a long shot. What am I missing here?

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Can these be printed without supports ? I was thinking of doing the filament bearing mod that you have added into this anyway and i really like the look of it. Its just I havent really used petg as yet so am not sure what I can get away with 🙂

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

@ButterworthDesign

Did u put as much attention to N4 as u did to N4A? I just printed N4 accourding the instructions and it took me quite some grinding to make the heatsink fit and the PFTE tube does not fit in by a long shot. What am I missing here?

I'm not sure... I'll look at the .stl's later tonight.

This is an overlay of the R4 parts in Pink, and the N4 parts in Blue. There's no difference here except the filament path shift.

I did notice that the .STEP file has duplicate motor covers, but I'm not sure if that made it into the .STL (it shouldn't have).

Do you have any pictures?

Can these be printed without supports ?

Yep - no supports necessary.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

@ButterworthDesign:

Does N4A acknowledge the issues that some are reporting the wider throat for the extruder body and neck grip?

As reported here.... https://github.com/prusa3d/Original-Prusa-i3/issues/119

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Does N4A acknowledge the issues that some are reporting the wider throat for the extruder body and neck grip?

No change to the tolerance has been implemented for the heatsink mounting point - it is still 12.2 mm dia.

My (anecdotal) experience so far: I've printed and installed two separate versions of these parts with these tolerances, and both times I have been completely unable to move or rotate the heatsink once installed and tightened.

That being said, changing the nominal dimension to 12.1mm is a good idea in my opinion, and I may incorporate that change in these parts if I have the time. Meanwhile, I have uploaded the raw STEP cad files, and that should be an easy change to make with a tool like Fusion360.

Strong recommendation: do some part prep/post processing after printing by placing some fine grit sandpaper (>200 grit) on a flat surface, and rubbing the mating surfaces of these parts on the sandpaper to flatten and remove any small nubs or spikes from retractions or z-hops. The best mating is achieved with smooth surfaces, and I have had a loose heatsink in the past caused by some of these small surface bumps.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Hmm, I had to print using a sub optimal extruder setup, perhaps that was it.

Now all parts are on and the filament goes through the extruder, smoother than ever 🙂

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Awesome! Great to hear. Enjoy, and happy printing!

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

As promised: I used it as part of this: https://www.thingiverse.com/thing:3502557

and remodeled the N4 extruder cover as part of my "UpsideDown" Idea ( https://www.thingiverse.com/thing:3502573 )

Im keeping things measurably cooler now 🙂

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Very cool (pardon the pun...)! Nice work.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

@ButterworthDesign - I am so glad to see your extruder fix. As with your experience, my MK3S extruder is making odd noises during fast E-axis movement. Also, I was concerned during assembly about how tight against the Bondtech gear the filament path was. Since I'm waiting patiently in line for my MMU2S upgrade kit I will probably do the extruder rebuild with your parts then.

Q: Do I need a updated Bondtech idler holder to match your mod? The MK3S -to- MMU2S upgrade has a different Bondtech idler holder than the stock 3S. Your MMU2S parts do not have upgrade idler holder for the MMU2S - will this be a problem?.

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Q: Do I need a updated Bondtech idler holder to match your mod?

A: Nope - no change to the MMU2S compatible idler was made, so the one that comes with (or is printed from the stock part) should work fine.

The sensor holder/extruder cover part did need to be adjusted to align with the filament path shift, but thankfully that doesn’t affect the idler.

Good luck, and let me know if you have any more questions! Happy printing.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Do you have a version that supports this X-axis upgrade? Looks like there is a different x-carriage and back in the description to get belt alignment correct on the MK3S.

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Nope, and I have no plans to do so. However, i’ve published STEP files with this design, so it should be possible for someone else to quickly mod it.

IMO, Vekoj’s design is very nice looking. It’s more accurately called a “mod” though, and not necessarily an upgrade. Many people use it and love it, but the belt alignment “issue” really isn’t an issue in my experience. There’s just not enough measurable torque going to be produced by a 1-2 mm offset in the carriage, and as long as the belt is flat on both sides the belt length doesn’t change during side to side movement.

The biggest advantage and improvement offered by the mod is the additional stiffness around the bearing mounts on the Z axis rods (as long as the clamps aren’t overtightened.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Thanks for the reply

I personally like the belt tightness adjustment change, it’s a little bit beefier than the older version without the bearing tightness adjustment. Guess I will just stick with the older since I have it printed and running already.

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

It's really easy to overtension, but as long as you're aware of that it works really well when both screws are tightened evenly.

I've incorporated the principle into an X-axis parts mod that I've designed, but I haven't published it yet. Thinking of doing it soon - it would be compatible with both 20T and 16T idler pulleys, depending on what someone has on hand or how they feel about belt positioning.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

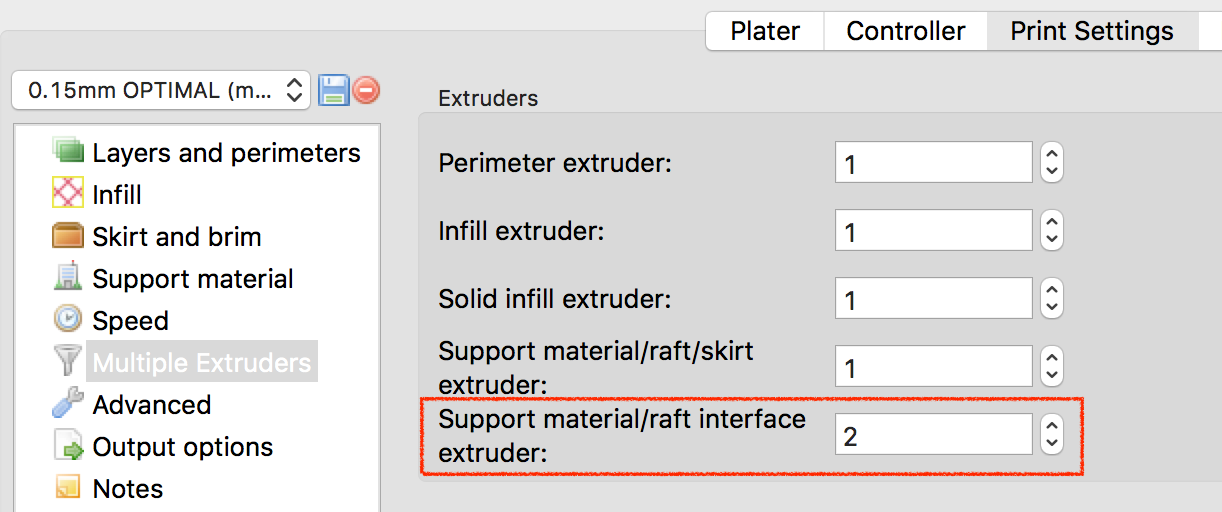

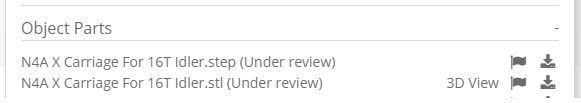

Update: I gave my previous statements above some thought and decided it should be easy enough to add an X-Carriage part with belt notch alignment for a 16T pulley (since it should just be a mirrored belt slot from the motor-side of the carriage).

Note: I don't have the ability to test this out myself, but if someone does, feedback is always welcome.

See the updated published files here: https://www.myminifactory.com/object/3d-print-86329

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Cool, I will try it out, it appears to line up exactly with the MK3S version not for the updated path.

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

it appears to line up exactly with the MK3S version not for the updated path.

I don't quite understand - can you post a picture?

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

In that thingiverse I posted, someone had posted a MK3S version for it in the comments I saw today that I was going to print. Here are both of yours almost superimposed on each other.

Printing yours currently, but probably won't get a chance to install til this weekend.

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Ah! I understand now. Yes, they should be exactly the same at the belt slots. The only difference is that my carriage would be a universal fit for both Mk3 and Mk3S sensor versions of my N4A parts.

Rock on, and happy printing!

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth