Has anyone tried the Bondtech CHT Nozzle shown on CNC Kitchen on a Mk3?

Seems they have now released a 0.4mm version which has piqued my interest. I saw the review of them on CNC kitchen and they looked good. Quite a lot for a nozzle though!

RE: Has anyone tried the Bondtech CHT Nozzle shown on CNC Kitchen on a Mk3?

I did not know they had an 0.4 version. I am using the 0.6 version with a print speed of twenty for PETG and it makes a nice print. Will try higher speeds later but for ten prints so far, I am happy.

It is installed on my MK2.5s with a Bondtech BMG extruder.

RE: Has anyone tried the Bondtech CHT Nozzle shown on CNC Kitchen on a Mk3?

Hey mate, do you mean max volumetric speed of 20?

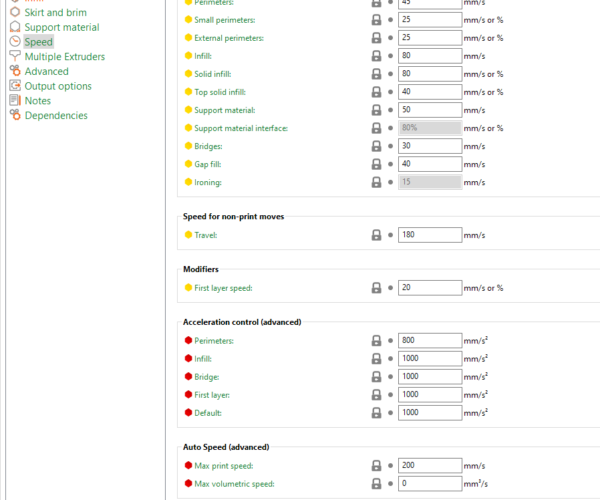

I'm interested, if you don't mind sharing, your "Speed" page for print moves on Prusa Slicer (see below)

I did not know they had an 0.4 version. I am using the 0.6 version with a print speed of twenty for PETG and it makes a nice print. Will try higher speeds later but for ten prints so far, I am happy.

It is installed on my MK2.5s with a Bondtech BMG extruder.

RE:

My setting is under 'filament settings/advanced/print speed override/max volumetric speed:20' the former setting was 9.

My 'filament settings/speed' sheet looks like yours, but the support material interface is 100% and my 'first layer speed' is 15

my MK2 has always been a noisy machine but with this new setting the sound is about 30% louder - the stepper motors are really working!

Yes $20.00 for a nozzle is expensive but there is nothing that you can add to your printer for $20 that will make a significant improvement. I printed a Bency and compared it with the old 0.4 nozzle and could not detect a difference except for the lettering on the stern.

As for CNC Kitchen, I find his show exceptionally reliable.

RE: Has anyone tried the Bondtech CHT Nozzle shown on CNC Kitchen on a Mk3?

I guess my question is, if you're just changing the maximum volume to 20 but not changing any of the speeds, how does that speed things up?

In my slicing tests it didn't make any difference unless I upped the speeds as well as the MVS.

MVS is most apparent with larger prints or when using larger nozzle sizes

I guess my question is, if you're just changing the maximum volume to 20 but not changing any of the speeds, how does that speed things up?

It's going to depend on the size of your print and other settings. The maximum volumetric speed setting (MVS - under print or filament settings) acts as an upper end throttle. So long as your layer heights, extrusion widths, and speeds are slow enough to stay under MVS, those settings will be used. If your print settings result in a flow rate higher than MVS, the more restrictive MVS setting will be used to cap speeds. You can view these results in preview mode. I've got some notes on this topic here that you might find useful.

In my slicing tests it didn't make any difference unless I upped the speeds as well as the MVS.

You're most likely not exceeding it. It becomes a big factor when you're printing with larger nozzles or large prints. You won't see any effect on a Benchy-sized model unless you crank MVS way back.

MVS can be set in 2 locations

My setting is under 'filament settings/advanced/print speed override/max volumetric speed:20' the former setting was 9.

My 'filament settings/speed' sheet looks like yours, but the support material interface is 100% and my 'first layer speed' is 15

You'll find the Maximum volumetric speed (MVS) setting in 2 locations:

- Under Print Settings->Speed->Auto Speed->Max volumetric speed (usually 0 in Prusa presets).

- Under Filament Settings->Advanced->Print speed override->Max volumetric speed (varies by filament)

If set to 0, the setting is ignored. If one or both of these are set to a non-zero value, the more restrictive (lower) setting is used to calculate maximum speeds based on your extrusion width and layer height settings. More notes on speed in general here, and determining MVS limits here.

Definitely increase volumetric throughput but with some caveats

Seems they have now released a 0.4mm version which has piqued my interest. I saw the review of them on CNC kitchen and they looked good. Quite a lot for a nozzle though!

According to the Bondtech site, they are based on the 3D Solex Matchless nozzles. I'm not certain exactly what their relationship is, but I've done a lot of experimenting with the 3D Solex versions, and they're quite impressive. I used mine extensively during the COVID PPE 3D printing push in early 2020 and they performed well.

They are somewhat expensive, but they essentially increase your hotend throughput with zero hardware or firmware changes. They're an ideal option when you want a bit more throughput but don't want to tear apart your Mk3.

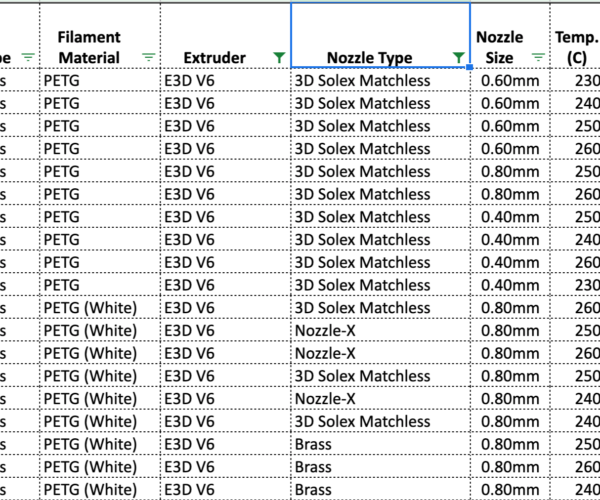

As far as performance gains, you see much more with sizes above 0.4mm. Here's a sample of my test data:

You can see all of the data here. Going from an E3D 0.4mm nozzle to a 3D Solex 0.4mm yields small gains, but things really take off with the 0.6mm nozzle. A 0.6mm 3D Solex Matchless can move filament faster than the Mk3 extruder can feed it (shown as the 70.55 rate). The nozzles are great, but a few caveats:

- They require more maintenance to keep clear due to the small melt zones paths. Cold pulls are tricky.

- The small bores are likely to clog up quickly if you try filled (e.g., wood) filaments.

- They are (AFAIK) only available as nickel-coated brass and not in hardened steel, so not good for abrasive filament.

Otherwise, they're a lot of fun. Until I got a higher capacity printer I kept a 0.6mm 3D Solex nozzle mounted.

RE: Has anyone tried the Bondtech CHT Nozzle shown on CNC Kitchen on a Mk3?

I think that might be the most comprehenisve reply I've had on a forum, ever. Thank you for taking the time to write that out and HOLY SHIT that website you've made is quite something.

People like you make the world go round.

One more question, because I am greedy, do you know if the default speeds on Prusa Slicer are just safe speeds, or can they be upped somewhat to take advantage of the higher MVS on bigger prints?

Thanks again

Seems they have now released a 0.4mm version which has piqued my interest. I saw the review of them on CNC kitchen and they looked good. Quite a lot for a nozzle though!

According to the Bondtech site, they are based on the 3D Solex Matchless nozzles. I'm not certain exactly what their relationship is, but I've done a lot of experimenting with the 3D Solex versions, and they're quite impressive. I used mine extensively during the COVID PPE 3D printing push in early 2020 and they performed well.

They are somewhat expensive, but they essentially increase your hotend throughput with zero hardware or firmware changes. They're an ideal option when you want a bit more throughput but don't want to tear apart your Mk3.

As far as performance gains, you see much more with sizes above 0.4mm. Here's a sample of my test data:

You can see all of the data here. Going from an E3D 0.4mm nozzle to a 3D Solex 0.4mm yields small gains, but things really take off with the 0.6mm nozzle. A 0.6mm 3D Solex Matchless can move filament faster than the Mk3 extruder can feed it (shown as the 70.55 rate). The nozzles are great, but a few caveats:

- They require more maintenance to keep clear due to the small melt zones paths. Cold pulls are tricky.

- The small bores are likely to clog up quickly if you try filled (e.g., wood) filaments.

- They are (AFAIK) only available as nickel-coated brass and not in hardened steel, so not good for abrasive filament.

Otherwise, they're a lot of fun. Until I got a higher capacity printer I kept a 0.6mm 3D Solex nozzle mounted.

RE: Has anyone tried the Bondtech CHT Nozzle shown on CNC Kitchen on a Mk3?

P.S I will get you data on Prusament PETG and maybe Prusament PLA if I have some when the CHT nozzles arrive

Default presets

I think that might be the most comprehenisve reply I've had on a forum, ever. Thank you for taking the time to write that out and HOLY SHIT that website you've made is quite something.

Glad it's useful. Let me know if you spot any errors.

[...] One more question, because I am greedy, do you know if the default speeds on Prusa Slicer are just safe speeds, or can they be upped somewhat to take advantage of the higher MVS on bigger prints?

I can only guess about how Prusa derives their presets, but I read a great article by the owner of Mad Maker (MM) filament (closed for now, unfortunately) in which he explained things from a filament manufacturer's perspective. In my mind, I'd always assume manufacturers did extensive testing (possible white lab coats) to develop "ideal" settings. The reality, MM explained, is that the manufacturer suggests settings that will work with most users with most slicers on most printers. That means they're trying to keep everyone, from the dedicated Mk3 owner to $200 clone hobbyist, from bothering them with complaints and returns. As a result, they tend to suggest higher temperatures (increased flow reduces adhesion and extruder problems) and slower speeds (better adhesion) that are likely to be needed. That's what got me started on my filament calibration kick. Now Prusa is a bit more like the Apple of 3D printing. If you use their filament on their printer, they have more control and their settings for Prusa branded filament seem very good. Others may just be user-contributed. I always view somebody else's presets as a starting point. I also finally figured out that buying every brand on sale leads to frustration, so have settled on a handful of filament brands and developing good settings for those.

You can definitely adjust those presets. I find that I can open things up a bit when using larger nozzles on larger prints (apropos the subject of this thread). For PETG in particular, higher temps with larger nozzles definitely allow printing at much higher MVS settings than the Prusa presets. (To their credit, Prusa is focusing on print quality not volume.) I was able to use 40mm^3^/s with PETG through a 0.6mm nozzle at 250C for mass production, for example. I've got some notes on optimizing printer output here.

P.S I will get you data on Prusament PETG and maybe Prusament PLA if I have some when the CHT nozzles arrive

I would very much appreciate any additional data you can add. @dimprov provided some much-needed info on the Creality Mk8 hotend and I'd love to have more. Keep in mind, my approach (the free air extrusions) is focused on identifying the "red line" maximum for your setup, not print quality. I usually end up cutting that maximum in half for production.

RE: Has anyone tried the Bondtech CHT Nozzle shown on CNC Kitchen on a Mk3?

Hello Bobstro.

After weeks battling with my MMU, I shut my system down for over a year. Now I'm back at it, and one of the things I've experimented with are the new CHT nozzles (after also seeing CNC Kitchens video). Honestly, I'm but a intellectual peasant compared to you, and I don't know what I'm doing. I have been very grateful over the years to follow your efforts of documentation and expirementation on your website. So a big thank you as always. I put the .40 CHT in and bumped every setting up 20ish. This Prusa is ripping now. Easily a 40% reduction in print time on 4 prints so far, and the quality, while not perfect, is pretty damn nice with Prusament PETG. I've attached my settings for your research.

Be safe.

Pete

RE: Has anyone tried the Bondtech CHT Nozzle shown on CNC Kitchen on a Mk3?

can you reuploud picture of your settings ? for me it is not opening 🙁

RE: Has anyone tried the Bondtech CHT Nozzle shown on CNC Kitchen on a Mk3?

Bondtech doesn't have an E3D V6 nozzle, can I use the M6 or will it be too long?

RE: Has anyone tried the Bondtech CHT Nozzle shown on CNC Kitchen on a Mk3?

Sorry. I'm not sure if I'm interpreting this correctly. The .6 nozzles solex/ccht nozzle seems like it can be set faster than .8 nozzle. Does this mean .6 is the optimum for this setup?

The value in Max volumetric override: MVS for generic PETG in prusa slicer is already set to 20 by default. Does this mean little speed gain from a .8 nozzle?