Using 0.5-0.8mm nozzles with Mk3 E3D V6 - Cautions or tips?

I'd like to experiment with larger nozzle bores for printing brackets and cases for cameras and Raspberry Pis. From reading the recent Prusa blog, I'm understanding that a thicker nozzle can still be used to print similar coarse line-heights as the 0.40mm (0.20-0.32mm) on up to 80% of the nozzle size, but can do so with increased line widths (up to 120% of nozzle bore), thereby reducing the number of passes required to print shell walls of the same thickness.

The Prusa blog didn't make any mention of speeds or temperatures required to do so. I know there's a maximum amount of filament that can be shoved through the E3D Mk6 hotend. Increased heat can help to a point, but I'm trying to determine what speeds will be realistic with different nozzle bores (likely 0.50-0.80mm). I suppose I can simply start slow with something like 20-30mm/sec. and see how far I can push things, but I'm hoping someone has done similar testing and can provide some shortcuts. I suspect there's a point of diminishing returns with larger sizes (>0.8mm) with speeds limiting any gains.

I'm also curious as to whether slower speeds matter much with smaller parts. Are acceleration settings going to impact print speeds more than lower print speed maximums? So long as I don't exceed the output of the E3D hotend, am I OK with the default Prusa acceleration settings?

Also, if anyone has experienced limitations with slicer software when going with larger bores, I'd appreciate any warnings. I'm comfortable with PrusaControl, Slic3r, Cura and Simplify3D, so can use whichever is best suited for the job. Any tips appreciated.

Re: Using 0.5-0.8mm nozzles with Mk3 E3D V6 - Cautions or tips?

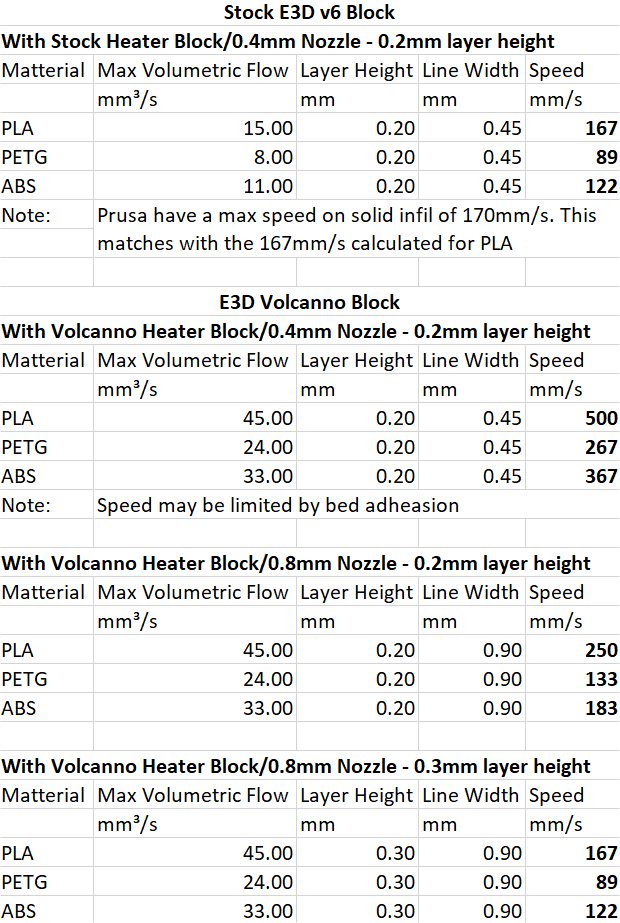

The maximum speed you can print at will vary by material. In Silc3er in 'Filament Settings/Advanced' there is a max volumetric speed. This is the limit at which the heater block/nozzle combination can transfer heat energy to the filament. The only way to increase the speed is to change the heater block from the stock 'E3D v6' to an 'E3D Volcano'. The Volcano can transfer 3 times as much heat energy to the filament.

The values for common materials are:-

So just changing the nozzle will not get you any more speed. However a volcano block can handle a 0.4mm nozzle as well as the larger ones so it would be suitable for your requirements providing you are comfortable in recompiling the firmware yourself to allow for the 8.5mm reduction in build height.

Regards,

Martin

Martin Wolfe

Re: Using 0.5-0.8mm nozzles with Mk3 E3D V6 - Cautions or tips?

Many thanks Martin! This gives me a good understanding of the maximum speeds achievable with a stock configuration.

If I read the recent Prusa blog entry on nozzles correctly, the advantage gained with a larger bore size for a given layer height isn't "speed", but the ability to lay down more material using wider lines at any given speed. So say a larger nozzle might be able to lay down a line twice as thick with fewer outline movements, thus finishing more quickly while moving slower. However, based on other reading and -- I think -- your data, the maximum extrusion rate measured in mm3/s is fixed, so a line twice as wide can only be printed half as fast. Is that correct?

I still wonder if there's an advantage to a larger bore if printing at less than maximum rate. Looking at the recent Slic3r settings, outer perimeters speeds for PLA in the range of 35mm/s are common, or roughly 20% of the extruder's maximum speed per your data. Might a single wider perimeter printed at 35mm/s still print faster than a thinner 35mm/s outer perimeter line + 1 or more inner perimeter lines at 45mm/s? For example, a 0.80mm nozzle printing at 0.96mm line width at 35mm/s would completed a 100mm wall in 1 pass (2.86 sec.) versus a 0.40mm nozzle printing a 0.48mm outer perimeter at 35mm/s and an inner perimeter at 45mm/s in 2 passes (2.86 sec. @ 35mm/s + 2.22 sec. @ 45mm/s = 5.08 sec.) My thinking is that, so long as the maximum extrusion rate is not exceeded, there is still a benefit to using a larger nozzle bore. While not moving faster, this will help when printing below maximum speeds (e.g. for outer perimeters).

The trick, I think, will be calculating reasonable speeds for non-perimeter lines so as not to exceed the maximum extrusion rate. Depending on the line mix, there may not be any net benefit, at least in terms of print times. I'm also not sure I understand how infill is impacted by thicker lines. I assume 20% infill lines will be fewer but thicker, so will require less time printing per-line, though at slower maximum speeds. This is where I get lost on the real-world benefits. I was surprised the Prusa blog didn't make any mention of maximum extrusion rates and the impact on speeds.

I'm sure I can calculate all this myself, but I don't have confidence in my understanding of all of the factors yet. I appreciate the effort you put into the table. Thanks again. Your data is answering other questions I had about overall speed limitations.

Re: Using 0.5-0.8mm nozzles with Mk3 E3D V6 - Cautions or tips?

so a line twice as wide can only be printed half as fast. Is that correct?

Correct.

The advantage to a larger bore comes when you want to lay down thicker perimeters or faster top/bottom layers as there the speed limitation is linear rather than volumetric to give a good surface finish. So with a 0.4mm nozzle a 1.8mm thick wall would take four passes of the nozzle but a 0.8mm would only take two. However an object that uses a lot of infill would not be any faster as that is where the volumetric limit comes into play.

Regards,

Martin

Martin Wolfe

RE: Using 0.5-0.8mm nozzles with Mk3 E3D V6 - Cautions or tips?

so a line twice as wide can only be printed half as fast. Is that correct?

Correct.The advantage to a larger bore comes when you want to lay down thicker perimeters or faster top/bottom layers as there the speed limitation is linear rather than volumetric to give a good surface finish. So with a 0.4mm nozzle a 1.8mm thick wall would take four passes of the nozzle but a 0.8mm would only take two. However an object that uses a lot of infill would not be any faster as that is where the volumetric limit comes into play.

Regards,

Martin

I am usually disappointed by forums, but you two just made my day. This was probably the best forum Q&A exchange I have seen in a long time. Concise, informative, non-condescending. Just great.

Cheers

RE: Using 0.5-0.8mm nozzles with Mk3 E3D V6 - Cautions or tips?

I am usually disappointed by forums, but you two just made my day. This was probably the best forum Q&A exchange I have seen in a long time. Concise, informative, non-condescending. Just great.

I'm glad you found this thread. That was the lightbulb moment for me with 3D printing and led me to a much deeper understanding of the 3D FFF process. There have been several generations of great posters and moderators here and we've all benefitted tremendously. Glad you're finding good info!

RE: Using 0.5-0.8mm nozzles with Mk3 E3D V6 - Cautions or tips?

Well the best I could squeeze out of my mk3s with a bondtech extruder running 0.8 nozzle at layer height 0.64 width 0.8 petg 1.75 filament prusament temps at 250 was 18 on MVS going up another 10c on temp did not do much gains just a glossier finish to the print.

Prusa i3 MK2s MK2.5s Mk3 Mk3s BearPrusa Zaribo 320 - Kit Build - Rc Driver - Tweak freak...

“I know nothing about surpassing others. I only know how to outdo myself.†-Bushido-

RE: Using 0.5-0.8mm nozzles with Mk3 E3D V6 - Cautions or tips?

Something else I have noticed (Using PETG), I seem to get less stringing with a larger nozzle size compared to 0.4mm, bridging seems to be more reliable and most importantly, interlayer adhesion is better, some of this is due to the extra surface area, but most will be the heat remaining in the filament after extruding due to the increased volume of material extruded by the larger nozzle, this will in effect allow it to melt into the previous layer for longer before cooling down.

Nozzle size on left in mm, area in middle, area increase of 0.4mm nozzle relative to 0.25mm nozzle, then the rest relative to the 0.4mm nozzle.

So for the 0.4 to 0.8mm nozzle, you may have twice the diameter, but you have 4 times the area.

| 0.25 | 0.049087 | |||

| 0.4 | 0.125664 | 2.56 | ||

| 0.5 | 0.19635 | 1.5625 | ||

| 0.6 | 0.282743 | 2.25 | ||

| 0.8 | 0.502655 | 4 | ||

| 1 | 0.785398 | 6.25 |

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.