Quieting the R3 blower design

I'm needing to run the part cooling blower at around 25% (maybe even less) to get a good print now. As a consequence, I guess beause of the PWM approach to fan speed (?), the blower motor makes a ton more noise than previously when it was running closer to 100% speed.

Is there a good way to muffle this new undesirable sound? Would maybe using a suitable size capacitor across the motor leads solve the issue? Or is there a better way?

Re: Quieting the R3 blower design

Here it is with the blower attached (and making a lot of noise):

and here it is with a 2200uF capacitor across the blower's power leads (resulting in ~95% less audible noise):

That last 5% of audible noise is still somewhat annoying, though I suppose I could live with it. It is certainly much better now than before the mod.

Re: Quieting the R3 blower design

Final thoughts: The PWM is operating at 500Hz. It is audible because human hearing is in the 20hz to 20Khz frequency range. So, if (?) the firmware can support a higher frequency PWM--something higher than the human hearing range--then that would solve the issue at the source.

Re: Quieting the R3 blower design

Thanks for the analysis. I will also try a 2200uF capacitor to reduce the noise.

Re: Quieting the R3 blower design

Be carefull with adding such a big Elko ! Now your fan is running with more then 25%.

Thomas

Re: Quieting the R3 blower design

Is there any reason not to do the PWM at a higher frequency? Will higher frequency PWM work just as well? Any downsides?

A brute force hack would be to decouple the blower from the Einsy, read the duty cycle emitted by the Einsy using a separate Arduino and then drive the blower with the same duty cycle, but using a higher frequency PWM. Overkill, but relatively easy to do. The only question I have is whether the higher frequency PWM would still drive the blower without it stalling out.

Anyone know?

Re: Quieting the R3 blower design

The output of the blower's tachometer isn't a nice clean signal like what I was hoping for:

I suspect that each group of four pulses above 1v represents one revolution of the blower motor.

Re: Quieting the R3 blower design

I did some experiments and found that if I drive the PWM at frequencies greater than 7kHz, then the blower is completely quiet. The default for the Prusa Einsy is just 490Hz. Moreover, at 7kHz PWM I can still drive the blower over its full range of ~200RPM to ~3000RPM.

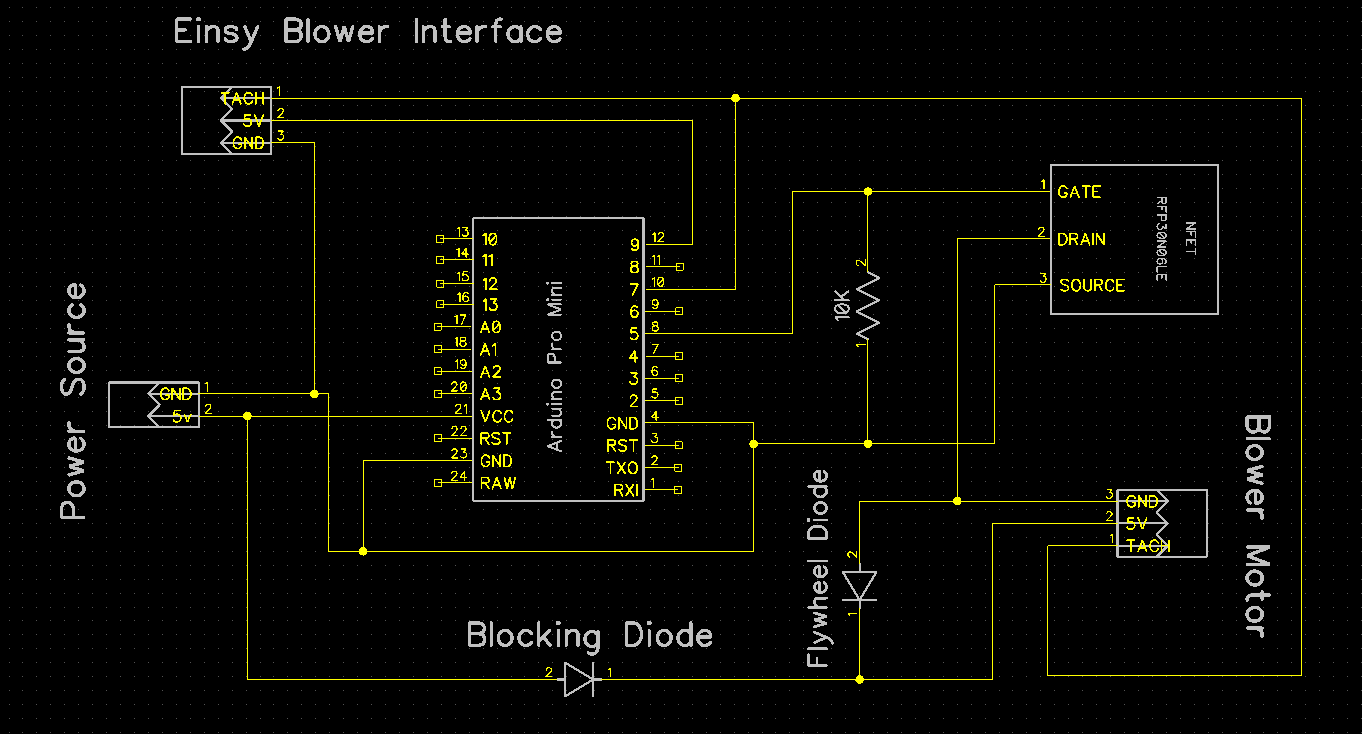

Therefore, I'll be doing exactly that, using an Arduino Pro Mini to measure the duty cycle output by the Einsy board and then converting that at an equivalent duty cycle at 7kHz frequency to the blower motor. This will work standalone without needing to change the Einsy board or the Einsy firmware. As you can see in the schematic below, the material cost is quite low. By changing the prescaler on the Pro Mini, a 7kHz frequency PWM is created.

Meanwhile, entirely separate from the above, the blower motor's tachometer output is truly strange:

I can't make much sense out of it. Can anyone reading this interpret it?

Re: Quieting the R3 blower design

Meanwhile, entirely separate from the above, the blower motor's tachometer output is truly strange:

Indeed.

The problem is that you're PWM regulating on the GND connection to the fan. The tacho signal is referenced to GND, so you are seeing a mix of the tacho and your PWM duty cycle. You should PWM regulate the 5V supply to the fan instead.

EDIT:

Maybe I am wrong about the above. Reading the Einsy schematic, it seems to be PWM regulating on fan GND too.

But then I don't get how you can read the duty cycle output from the Einsy by taking the positive fan output and connect it to a port on your microprocessor (and connecting the PWM regulated GND to your common GND).

Re: Quieting the R3 blower design

Final thoughts: The PWM is operating at 500Hz. It is audible because human hearing is in the 20hz to 20Khz frequency range. So, if (?) the firmware can support a higher frequency PWM--something higher than the human hearing range--then that would solve the issue at the source.

It does look like there is support for a higher frequency. In Configuration.h there is a define "FAST_PWM_FAN" that isn't enabled. It looks like enabling it will increase the frequency to 7.8 kHz, but also increase the temperature of the fan driving FET (Q2).

Re: Quieting the R3 blower design

Final thoughts: The PWM is operating at 500Hz. It is audible because human hearing is in the 20hz to 20Khz frequency range. So, if (?) the firmware can support a higher frequency PWM--something higher than the human hearing range--then that would solve the issue at the source.

It does look like there is support for a higher frequency. In Configuration.h there is a define "FAST_PWM_FAN" that isn't enabled. It looks like enabling it will increase the frequency to 7.8 kHz, but also increase the temperature of the fan driving FET (Q2).

It works! This is great. I had thought about changing the prescaler in firmware, but I was concerned about unintended consequences. This does it though, so I guess it must be OK.

The main consequence seems to be that of setting fan speeds. For instance, "M106 S100" now produces only 480RPM on the blower, and "M106 S120" produces maximum RPM. "M106 S101" produces 800RPM. So, as you can infer, the specifying range is both different and a lot narrower.

However, it is quiet! That's the important thing. It's a relatively small sacrifice to change my cooling settings in the slicer to get that benefit. 😀 😀 😀

Re: Quieting the R3 blower design

Final thoughts: The PWM is operating at 500Hz. It is audible because human hearing is in the 20hz to 20Khz frequency range. So, if (?) the firmware can support a higher frequency PWM--something higher than the human hearing range--then that would solve the issue at the source.

It does look like there is support for a higher frequency. In Configuration.h there is a define "FAST_PWM_FAN" that isn't enabled. It looks like enabling it will increase the frequency to 7.8 kHz, but also increase the temperature of the fan driving FET (Q2).

Well, I take it back. 😮 Maybe the temperature on the Q2 FET is a problelm after all. I just tried running it at different levels for a while, and the RPM's are meandering and not reproducing from one time to the next. 🙁 So, I'm afraid the firmware fix won't work, and my hardware solution (above) is now the only known solution that will work reliably and predictably for producing a quiet blower at 7kHz+ PWM.

The FET I'm using is quite robust and should handle the load no problem: https://www.sparkfun.com/datasheets/Components/General/RFP30N06LE.pdf

Something worth exploring would be to use the Q2 FET to drive my FET, which would be a little bit simpler than using a separate Adruino Pro Mini to manage the whole issue issue. That wouldn't place much load on the Q2 FET, so maybe it would work.

Re: Quieting the R3 blower design

Meanwhile, entirely separate from the above, the blower motor's tachometer output is truly strange:

Indeed.

The problem is that you're PWM regulating on the GND connection to the fan. The tacho signal is referenced to GND, so you are seeing a mix of the tacho and your PWM duty cycle. You should PWM regulate the 5V supply to the fan instead.

EDIT:

Maybe I am wrong about the above. Reading the Einsy schematic, it seems to be PWM regulating on fan GND too.

But then I don't get how you can read the duty cycle output from the Einsy by taking the positive fan output and connect it to a port on your microprocessor (and connecting the PWM regulated GND to your common GND).

I notice that the Einsy reads RPM's that are under 2000RPM as zero RPM, so maybe this is a factor in its inaccuracy.

I suppose, in general, high side switching is the approach which is least likely to result in unintended consequences? I'd need to procure another couple parts, but I could try setting it up that way instead.

Re: Quieting the R3 blower design

I suppose the right way to go would be to find out if the tacho is referenced to the high or low side, and then regulate on the other one. Time to dig for the datasheet on the fan.

Re: Quieting the R3 blower design

I suppose the right way to go would be to find out if the tacho is referenced to the high or low side, and then regulate on the other one. Time to dig for the datasheet on the fan.

If there is a datasheet for this fan, I'd love to see it.

Meanwhile, as an experiment, to eliminate PWM interface, I powered the fan using just plain 5v DC. I then measured the RPM's using a noncontact infrared tachometer as something around 4150RPM. However, the output of the fan tacho is:

which suggests about 4 pulses per revolution.

Now, if I were to power the fan at 7kHz at a 99% duty cycle, the measured RPM is 3760RPM, and the output of the tachometer, is:

Likewise, if I use high side switching to power the fan using PWM at 7kHz and a 50% duty cycle, then the RPM measures as 1380RPM, and the tachometer output looks like:

So, it would appear that even though the PWM frequency signal is mixed into it, it may still be possible to measure RPM's by looking at the larger structure.

Re: Quieting the R3 blower design

Looks like there is a need to filter out the PWM frequency from the tachometer to get the core RPM value read reliably. Could be that at some speeds of the fan the RPM value is being read when the tachometer voltage is 0 even if the RMS value is a lot higher.

Regards,

Martin

Martin Wolfe

Re: Quieting the R3 blower design

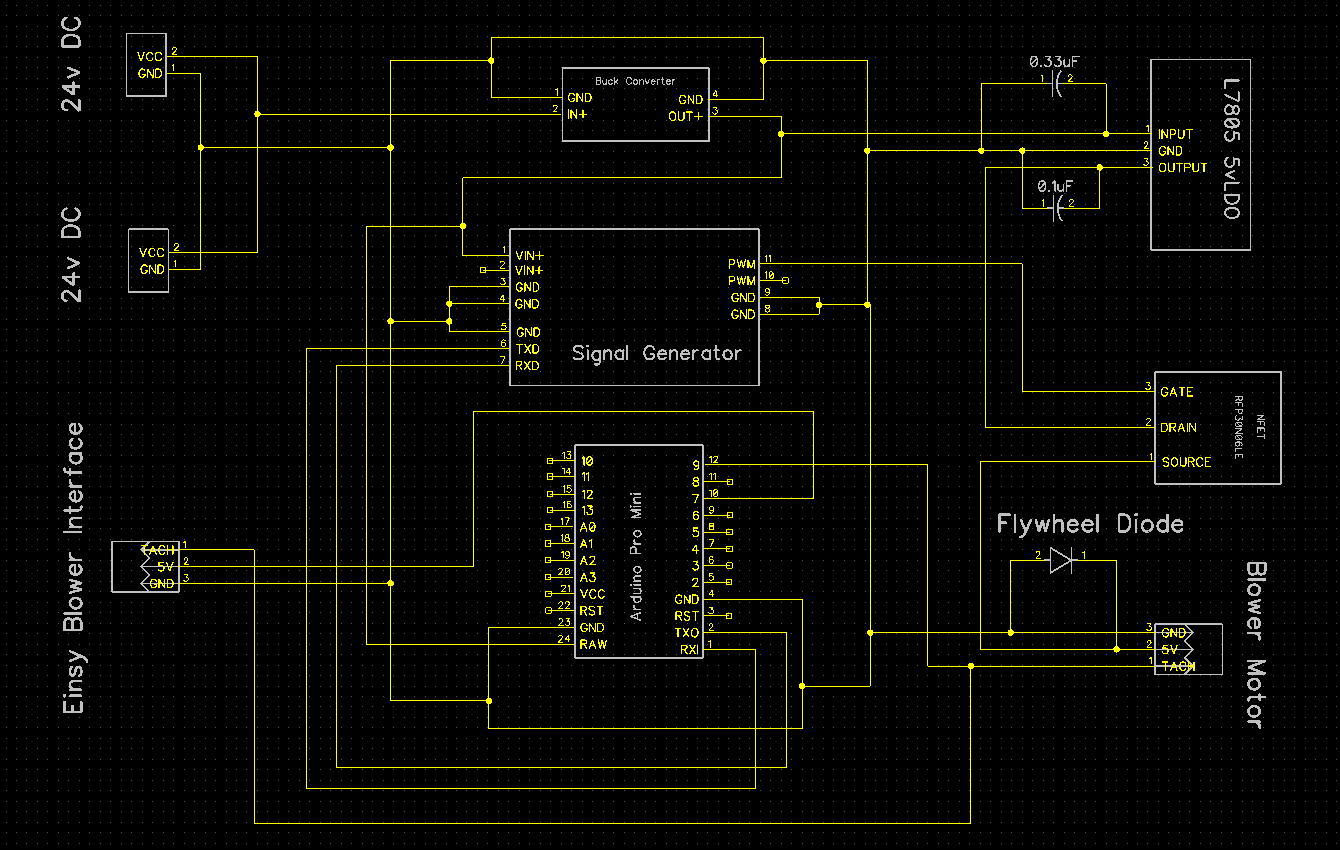

I wasn't getting a very clean waveform using just an atmega328p to provide the PWM frequency, so I decided to add a $3 signal generator. Here's the new schematic, which also does its switching on the high-side rather than, as before, on the low side:

Hopefully I will receive the remaining parts later today, and then I will build it.

Re: Quieting the R3 blower design

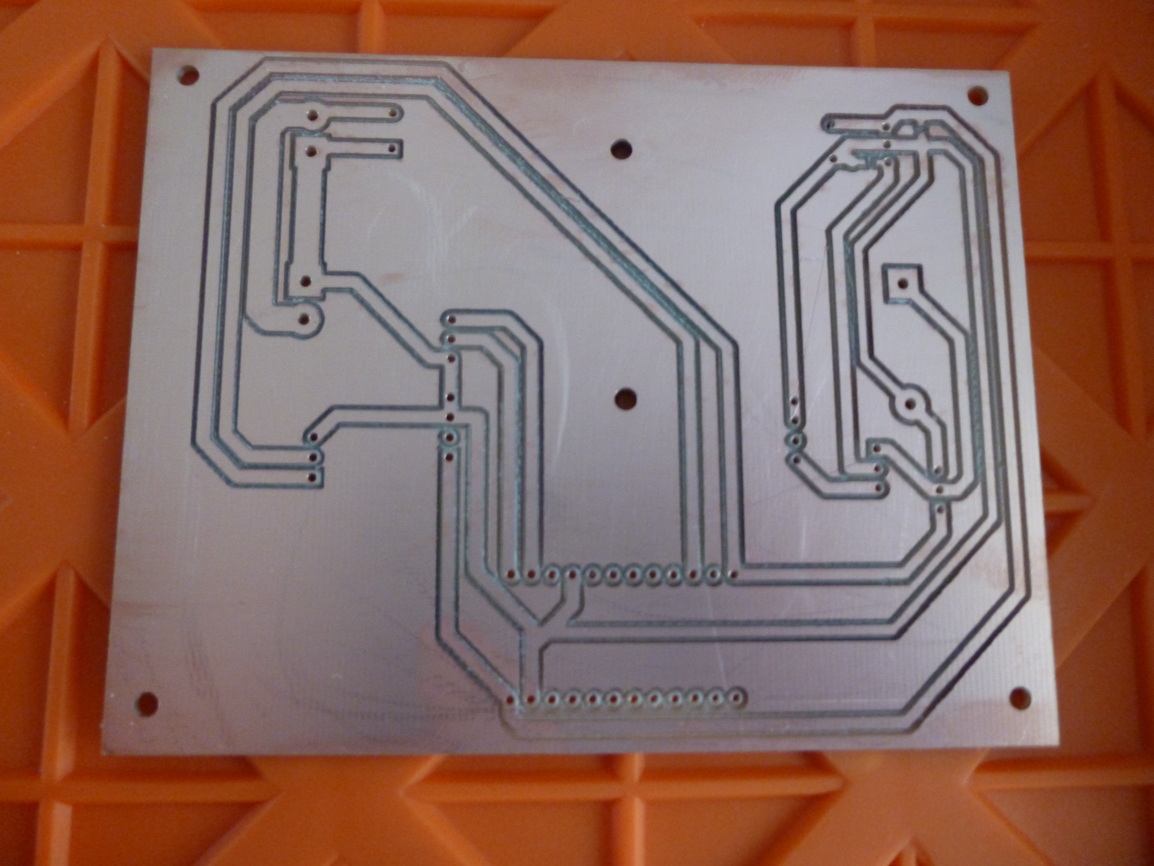

While waiting for the parts to arrive, I converted the schematic into a PCB using a 2418 CNC:

I included mounting holes so I can screw it into a suitable project box that I'll be 3D printing on the MK3. I hope to mount it onto the MK3 much like the way the Einsy is.

It has two 24v connectors: the power supply will feed this board directly and then pass-through to the Prusa I3 MK3.

The signal generator can be controlled over serial from the Arduino Pro Mini, which will also be reading the tachometer output of the Prusa part cooling blower. It will also read the duty cycle on the Prusa PWM so that it knows how to set a proper duty cycle on the signal generator when printing. This way I can dial-in RPM's, not just duty cycles, and that's better than what the Prusa I3 MK3 can presently do. 😀

Re: Quieting the R3 blower design

Sounds good. A proper feed back loop and set point to control it. Much more meaning full with 20% meaning 20% of max fan speed rather than 20% of max input power.

Regards,

Martin

Martin Wolfe