Problem with harderned nozzle

Hi,

Well it seems every time I try something new it kinda of fulls apart, in this case literally. I changed the brass nozzle for the hardened one as I wanted to print some kevlar and brass ABS's, but just after making the change,I needed to print some PLA so I re-setted the height etc, did first layer tests using the PLA and started the print. First layer good, second layer and or third layer complete disaster, it just stringed. I am at a loss what to do, do I replace the nozzle back to the brass one? If I do will I have the same problem with the ABS. I had been printing ABS (standard) for a few days now and had perfect results before the nozzle change. Is there something that needs to be changed to get the hardened one to work? Do I just use the brass ones and replace regularly?

Advise would be appreciated.

Jessica

RE: Problem with harderned nozzle

@jessica-kinchin, Being that your first layer was good to go but following layers were failing, I'd bump up the extrude temp a bit. Take a look at your slicer settings to see what temp your hotend is using for first layer and bump up to at least that. Most likely reason is the thermal properties of the newly installed nozzle.

RE: Problem with harderned nozzle

Whenever you switch from a higher-temp material (e.g. ABS, PETG) to a lower-temp material (e.g. PLA), you should clean out the nozzle and hotend completely. Otherwise, some filament can be left behind that won't melt out at the lower temp and create a partial blockage.

Read up on doing cold pulls. I also recommend cleaning filament as you can use it to flush the hotend at temps higher than the hot stuff (265C) but it will also melt out at lower temps (200C) in case some gets left over.

I re-do Live-Z whenever switching nozzles. I'll often take the opportunity to swap or wash off the print surface. It sounds like a hassle, but a good clean and Live-Z only takes a few minutes once you're used to the procedure, and those few minutes can save a long print from failure halfway through.

RE: Problem with harderned nozzle

Hi

Thanks for the tips I will certainly look at the cleaning between materials, however doing some more tests I noticed that the fan had a dramatic influence on the temp measured. I had not noticed this before so do not know if it is significant.

I usually print at 205C for a PLA that ranges to 210C and have had great success. This time I set the temp to 215 and also turned the fan off for the first two layers. As soon as the fan came on the temp dropped from 215 to 204 and it took a long time to recover. If I had been printing at my usual temp this would have pushed it down to 194, that I know is not good for the filament.

So my questions are this normal, should I reduce the fan speed? In cura I can get the fan to slowly increase over several layers is this possible in Prusa and if so how is it done?

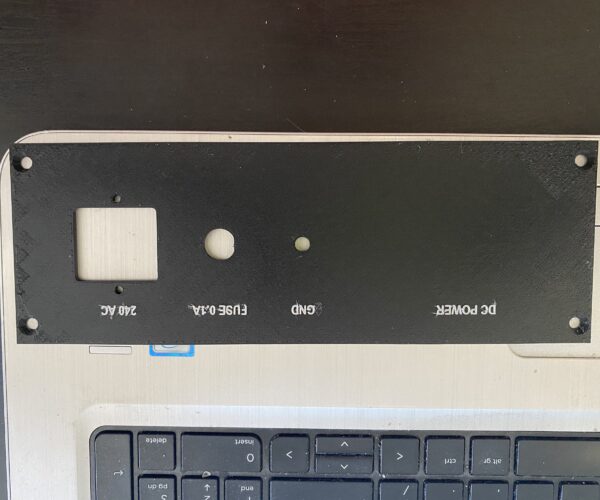

Using the 215 and waiting a layer before turning the fan on has allowed me to successfully print a 3mm block so I am going to try my panel with these setting and see if that prints too, the major difference is the cut out holes and total size of the panel.

Thank you all for your help

Jessica

RE: Problem with harderned nozzle

The best cure for the print fan kicking in is to fit a silicone sock. This has several benefits overall. One it stops the issue you are having, it means your extruder heater has to work less hard to maintain the temperature, it helps with clean up as it stops filament from sticking to your hot end if you do have a detached print/blob of doom.

Hardened nozzles are generally some form of steel, you need to bump your normal printing temps up 5-10 degrees when using them. This is entirely normal. My usual nozzle is an e3d Nozzle X. I print everything with that and I just made myself filament profiles adjusted for the changes I need and saved them. My default temp for pretty much all normal pla is 215. For silk pla its 230. For petg its 250. You just find what works for the materials you use in the setup you have.

Prusa Slicer doesnt have anything that lets you gradually ramp up the fan speed, however you can use the insert custom gcode at layer functionality to add fan control codes at whatever layer you want.

RE: Problem with harderned nozzle

I have a sock on the Ender, it came with it, I did not know the significance and it not being on the Prusa I did not think is was required I am using the e3d V6. I will search for one, the 215C is 5 C over the recommended temp of the PLA I use and generally it is a bit more stringy when at that temp, however it is seeming to print better with it so will continue with that, I guess if it cools quicker than the brass nozzle and the actual temp of the PLA is lower than the measured temp then it is probably behaving the same.

A slight side, is there any real differences in nozzles apart from diameter and screw, at some time I will need to get more and need a local UK low P&P cost solutions, there are hundreds on amazon for example?

Thanks for the advise

Jessica

RE: Problem with harderned nozzle

A sock is not 'needed' but I wouldn't run without one 🙂 Personally I think they should come as standard.

This is where being in the UK is a bit of an advantage, which is rare enough 🙂 . The hotend on the Prusa MK3 is actually sourced from a company called E3d. E3d is a British company. Its their 'V6' model (it has a slightly modified for Prusa heatbreak). Any V6 compatible nozzle will fit. The V6 style has been copied by lots of vendors. Actually most of the spare parts for V6 hotend will be drop in replacements. They also naturally sell the socks too and the e3d originals seem to last longer.

There is a massive difference in quality between an original and most of the copies out there. Being in the UK its easier to buy them direct from E3d. Although I have on one occasion bought an original E3d 3 nozzle pack from Amazon.

https://e3d-online.com/pages/spares#nav-target-v6

Materials temperatures on filaments are guidelines, not gospel. Its not known what printer setup the manufacturer used to come to the recommendations so its best to print some form of a temperature tower to see what is needed for your particular setup. Also remember that depending on what you are printing then the extra strength gained by printing hotter could be worth it for a bit of extra stringing. The fine strings you get are very easily removed with a blue flame from a small gas lighter torch.

Its all a balancing act. For pretty stuff, reduce the temp and minimise strings, for functional parts whack it up and post process afterwards.

RE: Problem with harderned nozzle

Finally have a print it still tried to come apart when the fan started up, but I reduced it to 160 in the tune setting and it continued to print OK. I have a lift in the corners that spoils the finish but it will have to do.

Finally have a print it still tried to come apart when the fan started up, but I reduced it to 160 in the tune setting and it continued to print OK. I have a lift in the corners that spoils the finish but it will have to do.

I have changed the filament setting to 50% so hopefully next time it will auto print at about the same level as used in the above tune

Not sure the best way to stop it raising at the edge I have previously tried all sorts of support and either they are not strong enough or too evasive and spoil the print I thought I had cured it as other prints before the nozzle change where not lifting

jessica x