MK3S HeatBed insulation

Hi!

Could it cause damage of heated bed if make insulation from the bottom of the bed?

Interested in insulation to speed up bed heating.

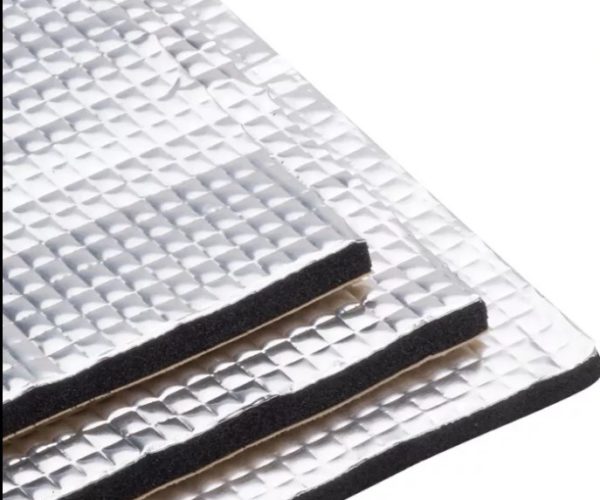

Want to use aluminium covered Heat Insulation Mat.

Of course, cork can be used for this purpose. But the forums say that this mat is better.

It is interesting to know if MK3S heatbed insulation could couse any damage of the printer.

RE: MK3S HeatBed insulation

I too would like to know if this would be a good idea.I suppose the objective would be to check if this will maintain an even temp across the bed.

RE: MK3S HeatBed insulation

It is interesting to know if MK3S heatbed insulation could couse any damage of the printer.

Why should this cause damage to your printer. Let's think what happens when you add this insulation.

The possibility for the heat at the bottom of the heating bed to simply radiate. is reduced. Thus, the required heating power is reduced because of reduced losses. The heating bed of the Prusa is temperature regulated - so it does not get hotter than usual. It is possible that the temperature distribution will be more even - this remains to be proven / measured.

For the y-axis, the mass increases slightly - but the stepper manages this. You will not be able to recognize any negative effects here.

So, from my point of view, you can install such an insulation without any worries - I haven't done it yet, but I will do it.

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: MK3S HeatBed insulation

@clemens-m

Thanks Clemens,Looking forward to your feedback after installation.

RE: MK3S HeatBed insulation

What I have forgotten:

It is important that the insulation material can handle the highest temperature the heatbed can receive !!!

(Which is something about 120 to 130 °C - if you have no bedboost or something like that)

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: MK3S HeatBed insulation

@clemens-m

PID-calibration! Is it needed after installation?

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.5.0+win64, Fusion 360, Windows 10

RE: MK3S HeatBed insulation

@ringarn67

Most Definitely I would say......

RE: MK3S HeatBed insulation

@capn-stretch

Completely right - because you change the characteristic of temperature flow through the structure it makes absolutely sense to do a PID-calibration!

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

follow up

Any update on the pros and cons of this mod?!

RE: Cork board might be a better approach

I've using these 12"x 12"x 0.25" cork boards for 2+ years on my 4 printers. No issues.

To install, you just need to pick away a few bits to clear the bolts for the Y- bearings which takes 15 minutes.

The drawback is more mass for the Y-motor to move so if you are already printing at the speed limit you may need to reduce speed a bit ti minimize ringing artifacts.

The benefit is lower long-term power consumption (5-10% in my unheated garage) and slightly faster warmup.