can you help me please

i had set my 3d files to print in ABS and some parts needs supports so through slic3r i activate supports but every time i run the print process it start perfect as all the parts first layers are 100% perfect but when the printer start to add the support first layer it add and for some reason its not sticking to the bed which destroy all the print 🙁

i tried to change the spacing from support setup to be smaller and nothing have changed.

can you help me here please as am still new to 3d print world 😛

Re: can you help me please

If you're new to 3d printing, i'd strongly recommend to start with PLA filament, it is a whole lot easier to print with.

Did you already try the usual methods to increase adhesion?

- thoroughly clean the bed with Isopropyl alcohol

- apply a thin film of the glue stick that came with the printer to the area where the print is going to end up on the bed

- maybe lower nozzle distance using Live-Z adjust some more

Re: can you help me please

And print slow... especially supports can be hard to get stuck to the bed.

And what Stephan said, put your ABS to the side, if you don't need ABS for some special reason (I cant think of anyone though, there are other better options)

Re: can you help me please

thank you all for your replay

will i have tried PLA many times before but i thought lets start with abs now as am printing thing that i need to be so strong and the ABS was the best for it 🙂

about the speed for the support any recommad speed for it

i dont think that the nozzle Z level or bed temp have any issue as with the main subject its work perfectly the only issue i have is with the support

Re: can you help me please

thank you all for your replay

will i have tried PLA many times before but i thought lets start with abs now as am printing thing that i need to be so strong and the ABS was the best for it 🙂

about the speed for the support any recommad speed for it

i dont think that the nozzle Z level or bed temp have any issue as with the main subject its work perfectly the only issue i have is with the support

Give PETG a try instead, it have similar characteristics

Re: can you help me please

guys i re cleaned the bed and slowed the nozzle for supports then for the first time i used hair spray instead of glue stick and it works like magic 😀

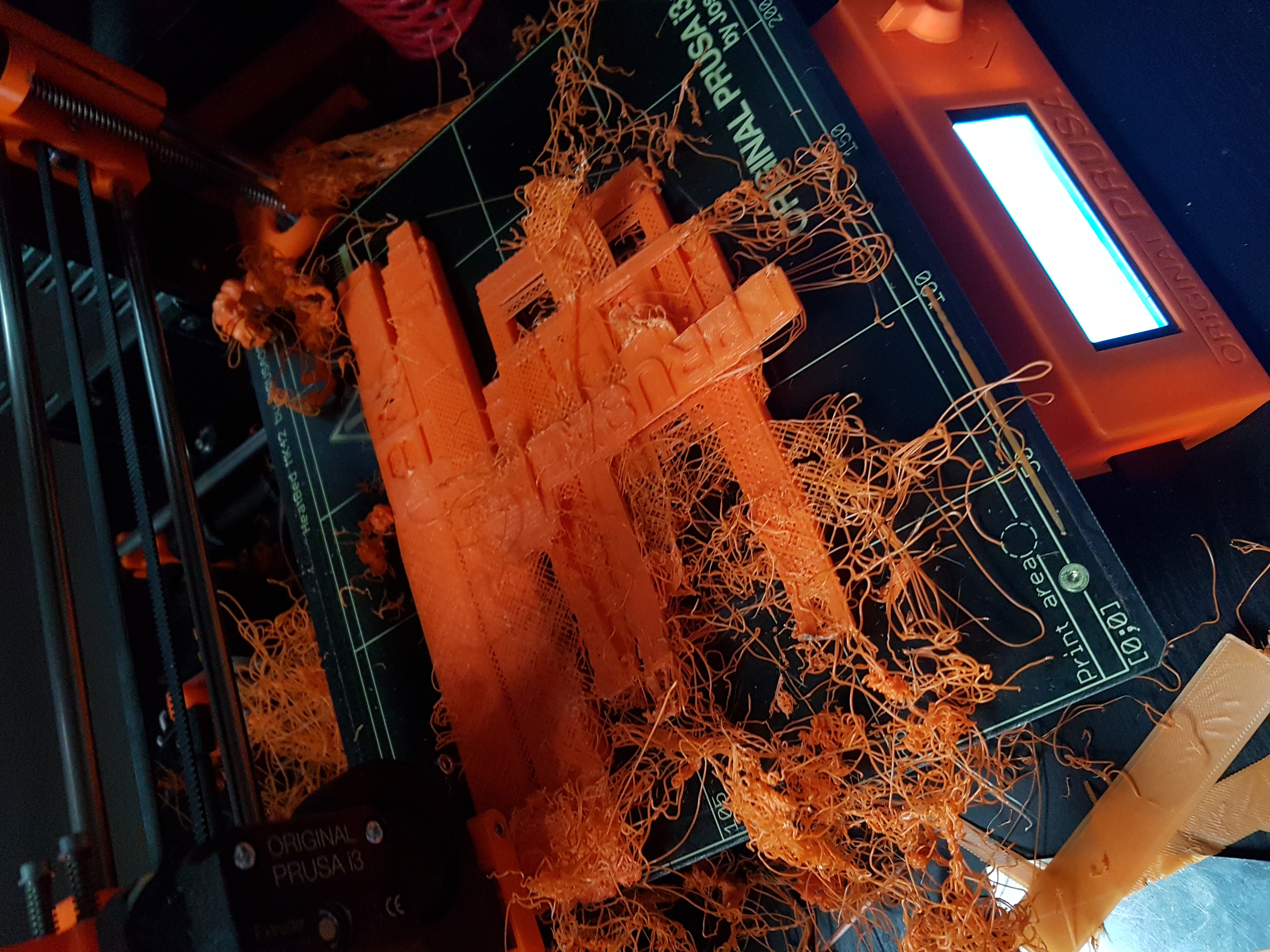

will this was for the beginning as after 5 hours when it finished 40% of the work and i checked it and it was working so perfect (never was that perfect before 🙂 ) then i went to my bed and when i wake up i was so shocked to see the plastic every where and the print was ruined and when i was cleaning the mess i found that the printer was shifting many time what cause all this mess so i re calibrated my printer and started again from zero but this time when it reached 20% it started to shift again 🙁

how can i solve this issue??!!

Re: can you help me please

Is it orange ABS from Prusa? It is quite tricky to print objects with large overhangs with this filament.

Reduce hotend temperature to 230-235°C (240 max), increase bed temperature as high as possible (110°C), increase Z-lift to 1mm, optionally print in high power mode. Do NOT use front cooling fan. Consider closed environment for printing ABS, in such case stay on 90°C on heatbed.

With this settings ABS should stick quite well (on really clean bed) and should not curl that much.

Alternatively use ABS-T (it is a bit nicer) or PETG.

Re: can you help me please

the mess i found that the printer was shifting many time what cause all this mess

What do you mean by shifting?

If the printed object got lose and ended up in a different location, then we still ne to work on adhesion

if the print "shifted", i.e. a straight wall suddenly became offset, then you might want to check belt tension, are all pulleys tightened, etc. for the axis the shift occured in.

Re: can you help me please

Is it orange ABS from Prusa? It is quite tricky to print objects with large overhangs with this filament.

Reduce hotend temperature to 230-235°C (240 max), increase bed temperature as high as possible (110°C), increase Z-lift to 1mm, optionally print in high power mode. Do NOT use front cooling fan. Consider closed environment for printing ABS, in such case stay on 90°C on heatbed.

With this settings ABS should stick quite well (on really clean bed) and should not curl that much.

Alternatively use ABS-T (it is a bit nicer) or PETG.

thank you david

no the ABS from Hatch BOX and am using hotend temperature 225°C and bed temperature 100°C i will try today to increase the bed temperature and see what will happen

Re: can you help me please

the mess i found that the printer was shifting many time what cause all this mess

What do you mean by shifting?

If the printed object got lose and ended up in a different location, then we still ne to work on adhesion

if the print "shifted", i.e. a straight wall suddenly became offset, then you might want to check belt tension, are all pulleys tightened, etc. for the axis the shift occured in.

i think you are right here as last night the moving of the nozzle head was little noisy and sharp so maybe the belt need to be checked