Problem with PETG

I'm trying to print a part in PETG. It print just fine in PLA but fails when i try to print in PETG. I'we tried to print other models in PETG (same brand)before with great results. The problem is that the corners is building up faster the the sides. Does enyone have a clue what the problem might be?

RE: Problem with PETG

Maybe your bed temp is too low? Try increasing your bed temp to at least 80C.

I was about to post about a related question, and I think I have an answer for your problem.

What I learned yesterday is that with PETG sides or corners pulling up is because the bed temp is too low. Yesterday I was trying to print what was is basically a flat bar (about 7in x 2in and maybe 0.5in tall). Twice, the left side pulled up enough to ruin the print because when the print head was moving over that edge, it was springing up and down a little, so the top layers were getting laid down on a moving base.

I had some MakerGeeks PETG, and the label on the spool said 60C bed temp, so in PrusaSlic3r, I setup a filament for that based on Prusament PETG, but changed the temp to 60C for both first and future layers. When I read about bed temp, I looked at two PET profiles built into PrusaSlic3r and saw they were both 85C/90C. I tried 80C/85C (80 on first layer, 85 on the rest) and the part came out ok. It's a little warped, but I may have done that by taking it of the build plate too soon.

So looking around, I see many spools of PETG from various companies that recommend a 60C, but clearly Prusament PETG recommends 85/90C and I got better results with two different PETG spools at at least 80C. Why the difference? I'm on an MK3. Is it the magnetic spring steel build plate?

RE: Problem with PETG

I haven't had any problems printing PETG as long as these few condition are true, this is on a smooth PEI sheet.

1. Spring steal sheet is clean

2. First layer height is good

3. Heat bed is flat across the whole surface when at printing temperature. I had to fix all three of my mk3/s heat beds when they were up to temperature because they would warp so the whole surface or the bed wasn't flat. That would cause small parts in lower areas of the bed to not stick well and corners would warp. With big parts if a corner was in a lower area it would warp as well.

4. For PETG bed temperature I run at 85c first layer and 90c for the rest of the part. For small parts like what's in your picture I would really slow down the speed.

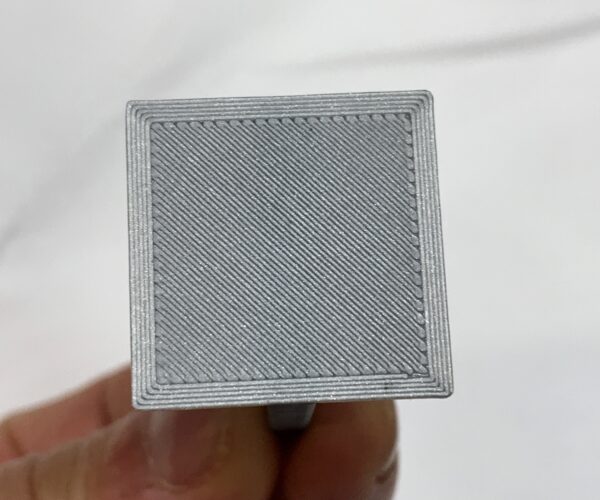

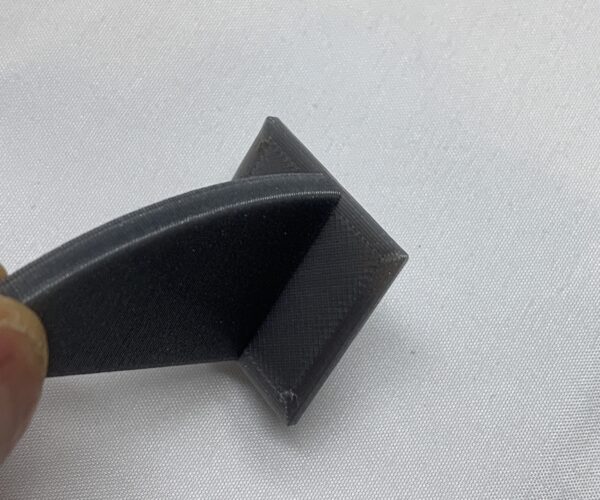

Here a few pictures of PETG parts that the base size looks close to yours.

RE: Problem with PETG

had the same problem and it helped to fix it. Thanx for this..

RE: Problem with PETG

@gkmakeit - I just have to add - that is a really pretty part!

Bottom, sides - the whole thing...

What nozzle, increment, infill and filament is that?

RE: Problem with PETG

@robert-rmm200

Thank you!

I'm using the standard 0.4mm brass nozzle that the mk3 comes with.

0.3mm layer height.

100% infill.

Unless they don't have the color I strictly use Atomic Filament for PETG. Made in the America with free two day fedex shipping within the US and most filaments have the +- 0.02 tolerance.

I don't know how much of a difference the "mods" I've done make, but I'd like to think it helps some. I replaced all the Y and Z brackets with billet aluminum ones. I also had my nozzle ceramic coated on the outside. Ceramic coating it hydrophobic (supper slipper so less sticking) and it helps with regulating temperature.

RE: Problem with PETG

I have been using .2 mm layer height for surface smoothness - because it is half the nozzle diameter.

But after seeing your surface finish at .3 mm - I may have to try that...

RE: Problem with PETG

I have been using .2 mm layer height for surface smoothness - because it is half the nozzle diameter.

But after seeing your surface finish at .3 mm - I may have to try that...

The look of thicker 0.3 layers has grown on me over time for large parts. I did most of my LACK parts at that height, except where I had to dynamically drop the size to avoid supports on overhangs.

RE: Problem with PETG

3. Heat bed is flat across the whole surface when at printing temperature. I had to fix all three of my mk3/s heat beds when they were up to temperature because they would warp so the whole surface or the bed wasn't flat. That would cause small parts in lower areas of the bed to not stick well and corners would warp. With big parts if a corner was in a lower area it would warp as well.

Could I ask how you achieve this? The heat bed is bolted down and as far as I can see there is no means to level the bed as I thought the mesh bed levelling coped with this. I am having a repeated problem in the bottom right corner of my Mk3s

RE: Problem with PETG

Some people also do one I think is call nylon nut leveling, something like that. I never tried it so I can't talk much on it. The way I did it gives the heat bed room to deal with the thermal expansion / contraction.

Here's a link to how I did mine. It's pretty easy after you get the gist of what I'm doing.

RE: Problem with PETG

@gkmakeit

Thank you for this. I'll get on with this later today.

regards

Aiden