MK3S with Sunlu new PLA+ filament

I used SunLu filaments for a while with very good results. When the boxes changed from black and white to brown I got big problems in getting first layer stick to the bed (both powder coated and pei sheet).

The strange thing is that old filaments are working fine (and bed leveling is correct) and it seems that something has to be changed in filament config (that simply does not stick).

Did someone succeded already in getting new SunLu PLA+ to be printed on prusa? Which config did you set?

now I am going to try with hairspray and even test a mixture of honey and water to get a better stickness.

Do you have anything to suggest?

RE: MK3S with Sunlu new PLA+ filament

Bump up the nozzle temp to 230C. Reduce the speed for the first layer to 10-20mm/s. Consider using glue stick.

I've no idea what they have put into the filament but it feels like oil infused.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: MK3S with Sunlu new PLA+ filament

I'm currently actually using some I recently bought and it's sticking just fine after a bed wash (because I was lazy and didn't put on gloves and got fingerprints on it)

RE: MK3S with Sunlu new PLA+ filament

Hi,

Although I am still awaiting the arrival of my first Mk3 I am researching documentation so as not to be blind-sided once I get started.

I have used the Sunlu + on another printer with great results, it is quite strong and prints perfectly. I was using a bed temp of 68 on the first layer and dropped to 63 from there on. The extruder temps were 217 or 218 first layer and one degree colder for the rest.

If you develop a successful profile I would appreciate it, my printer should be here sometime in January,

Phil Weber

Stay safe and healthy, Phil

RE: MK3S with Sunlu new PLA+ filament

@pcweber

For SunLu PLA+ filaments I am using these settings with MMU2S to have good tips:

- Brown box (nozzle range 190° to 230°): nozzle 210° first layer 203° others, Bed 60° (use hair spray for a good first layer, use pei sheet)

- Black box (nozzle range 200° to 230°): nozzle 215° first layer 207° others, Bed 60°

In case you are not using MMU2S you can go with 215° + 207° and 60° bed for both types of filaments.

Bests

RE: MK3S with Sunlu new PLA+ filament

@michele-b3

Thanks,

Once I get my new machine, after building it, I'll be doing my first prints with sunlu pla+.

Best Regards,

Phil

Stay safe and healthy, Phil

RE: MK3S with Sunlu new PLA+ filament

It's my first time printed Sunlu PLA+ (brown box: 190-230C) with Prusa MK3S (no MMU2S). It failed at the beginning with PLA profile. On each corner or end of a line, there's extra material (lump) leftover and later collided with nozzle. I tried change the nozzle and bed temperature, nothing helped. After I experiement with PETG material, I found Sunlu PLA+ felt very like soft PETG material. So I did the following:

- Create a PLA+ profile based on PLA, and in "Filament Overrides" enable "Lift" with 0.2mm (Same as PETG profile), no other changes;

- Put blue tape on my PEI sheet (this is equivalent to lower Z by a very small amount)

And succeeded with very good print quality. Sunlu PLA+ showed very good adherence on blue tape, same (or stronger) than PETG (I also print it on blue-taped PEI sheet).

RE: MK3S with Sunlu new PLA+ filament

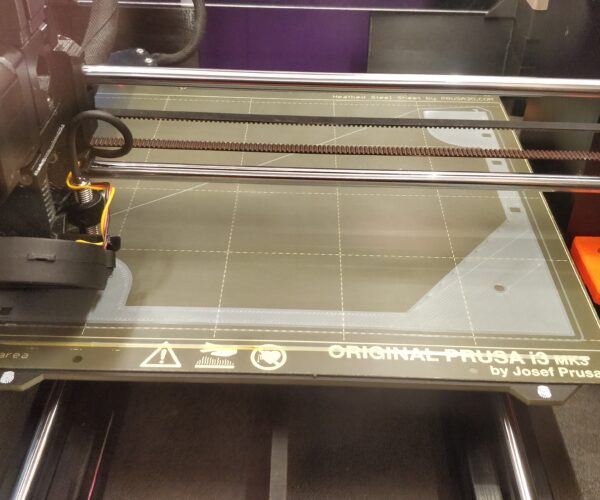

As one can see in the image the first layer is practically perfect. The holes, either square or round, along with the perimeter get printed first. Therefore, no corners lift off the bed. Just a clean bed with a z-axis perfectly aligned and a clean nozzle are required.

The printer got here as a kit, I built it and the had issues with the filament. I've discovered that this filament may start sticking to the bed prior to being perfectly dialed in on the z-axis and thus not sticking to the corners. Then again, any residue from previous builds on the bed causes similar results. Finally, a dirty nozzle plays a big part in adhesion.

Dialing in the temperature as well as the flow of this filament eliminates any blobs. I run at 213° C with the flow at. 96. Since I use the MMU2S the temperature needs to be at least 5 degrees cooler, after the first layer, to maintain good quality filament ends. This makes for consistent tool changes without intervention. The bed temperature also has a role in achieving good adhesion, I run at 68°.

The bed, I keep it very clean using kitchen detergents and light scouring pads, blue made for Teflon. Following PETG prints IPA keeping residue to a minimum.

Printed the 3X3 test pattern fine tuning the bed adjusting the bed level correction. I've only got a - 2 on the left side though. Rather than running the 9 point bed leveling prior to printing I run the 49 point test instead.

I've never used the blue tape before; however, if the tape brings the nozzle closer to the print surface, then perhaps a little more negative live-z calibration would give you the same results.

I get great, as well as, consistent results from Sunlu PLA+. It matters not that I change nozzles for a faster and stronger print if detail isn't required. Cleanliness and perhaps perfect height play a crucial role in consistent performance of this printer with this filament.

Phil

Stay safe and healthy, Phil

RE: MK3S with Sunlu new PLA+ filament

Well done Phil.

I solved first layer adhesion with some hairspray (it works perfectly and you can clean it very easily).

For mmu2s I can strongly suggest PrusaSlicer Dribbling. It is a fork of the original prusa version managed by Antimix.

In the dribbling edition you can set many different temps so than filament switch can be made very easily even with different materials (e.g. pva for soluble interfaces or supports).

i will test your settings for sure even if the temps you are using seem a bit too high for my previous tests.

Bests,

RE: MK3S with Sunlu new PLA+ filament

@michele-b3

I continue to get consistent results from the white pla+, but I'm having great difficulties with their pla wood. I am considering a return to Amazon since it is clogging terribly. It prints well for around 25 layers and then starts clicking at the hot-end. I believe that fiber is blocking the nozzle and then gets freed up but is at that point doing air printing. I just lowered the temperature setting in hopes that this will solve the issue, if not a return will be called for. This fiber releases a lot of powder leaving residue in the mmu, which is annoying, to say the least. That's where I have come to the conclusion that there is something wrong with this stuff.

If you have used this filament could you please give me somewhere to go.

Phil

Stay safe and healthy, Phil

RE: MK3S with Sunlu new PLA+ filament

Wood filaments are generally very clone to nozzle clogs. Haven't used the sunlu version but I've used a couple of other brands and I don't print with them unless I have a 0.6mm nozzle now as there is too great a risk with the 0.4mm. I find that even bumping the temps up doesnt really help as the wood particles just eventually clump together and at that point its clog time, unload and print a few more layers, just for it to happen again, and again.

So far I've not had the issue with the bigger nozzle.

RE: MK3S with Sunlu new PLA+ filament

@neophyl

I did indeed return the filament to Amazon, later I tried ColorFabb, and got worse results, then I measured the width of the filament, it ran anywhere between 1.82 and 1.93, that's been returned as well. Got another delivery due in on Monday it is SainSmart with a tolerance of +- 0.02mm the price is really good so I hope that the material is as good as the price. Their PETG filament has given me excellent results to date. I was surprised at the results of the Colorfabb reel, but then sometimes if the storage has gone through extreme temperature changes the filament may just get bad.

Phil

Stay safe and healthy, Phil

RE: MK3S with Sunlu new PLA+ filament

I've been printing some small pieces with the Sunli PLA+ Black filament. I had a lot of problems until I used a glue stick on the print surface and just used the generic PETG setting (yeah, weird, eh?) in the slicer. Hope that helps someone in the future.

RE: MK3S with Sunlu new PLA+ filament

@skinny,

I can't argue the Petg settings for initial bed adhesion, but the use of a glue stick with this filament troubles me. In the past five months since I built my mk3s kit with the mmu2s modification I've printed 30 reels of sunlu+ without ever using a glue stick.

The major caveat with this filament is that it will only print if three conditions are met:

- The bed must be perfectly clean I use dish washing soap without any additives, in between prints just plain old IPA

- First layer calibration smooth, the bead of filament won't stick unless the nozzle is close enough to the hot bed surface. The bead must print flat and the final patch without any holes or space between the lines. When you remove the filament from the bed the lines of the patch do not come apart.

- First layer temperature at 217°C the following around 210°, the lowered temperature after the first layer keep filament ends nice and perfect.

I don't print Sunlu filament on the textured sheet because it, and most pla, won't adhere well to it.

Good luck

Phil

Stay safe and healthy, Phil

RE: MK3S with Sunlu new PLA+ filament

Ah, sunlu PLA+.

Wasn't the first time we saw this, won't be the last.

TL;DR they coat it with something or it has an additive that doesn't play nice with PEI.

I have a piece of buildtak-type surface (the free stuff you get with Overture) on a separate steel sheet that I use for the remaining PLA+ I have. I won't be buying more from them. First roll went fine, no end of issues about halfway through the second roll.

RE: MK3S with Sunlu new PLA+ filament

@vintagepc

Interesting observation although I have to discrept with it. Simply keeping the bed clean has been a consistent winner for me. I do admit though that what I outlined above is how I get consistent prints from this filament. I've used others for my purposes always with problems, just dialing in all issues makes this work for me.

Best Regards,

Phil

Stay safe and healthy, Phil

RE: MK3S with Sunlu new PLA+ filament

@pcweber

I've never seen a smoke coming out for a PLA filament at 210C ... until I got Sunlu PLA+ filament. They definitely adding something to avoid friction and clogs. It's either coating or part of the filament. Anyway, this is a no-go for me because I don't know what's inside and for sure don't want to inhale this stuff.

Of course you can bump up the temp, wash the bed, squish the first layer like on your pic above. This is how I got my rolled used instead of trashing it. But there are many other brands out there which producing better PLA. That's why I avoid SUNLU filament.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram