Re: Large prints lift off bed

hmmmm... do prints that start from octoprint respect your live z adjustments?

Re: Large prints lift off bed

What material are you printing?

Large objects warping is a very common and difficult to solve problem. And the devil is in the detail, regarding temperatures, materials, shape of object, supports / brims / printed enclosures / location on print bed etc.

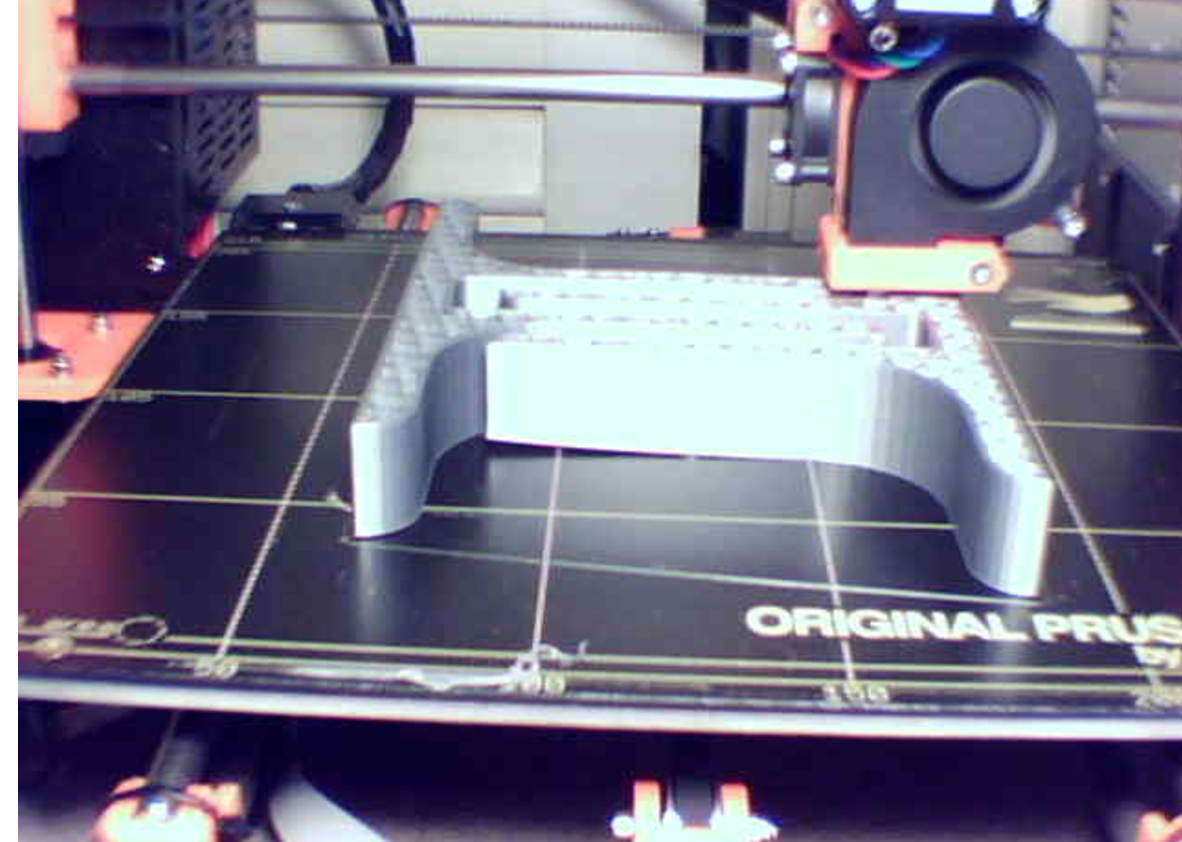

Looks like your object warped and lifted in the middle of the bed, not sure from the photo. Most of the time large objects seem to warp on the outer edges, that's if it is due to cooling more rapidly there. If it warps in the middle where is might be the warmest, then maybe your PEI surface is not as sticky there.

Re: Large prints lift off bed

Once you manage to print very large objects without lifting off the bed, you may notice that it lifts the PEI sheet off the bed, or even warps the entire bed. The warping forces are much stronger than you expect at first.

Re: Large prints lift off bed

Try to print one singe object, or at least don't put them that close. I would think that this could cause to uneven cooling and leads to warp. Also try a brim?

Also what are your slic3r (?) settings? Cooling?

How do you clean your printbed?

Carsten

My Prints: https://www.prusaprinters.org/social/15695-carsten/prints

My Employer: https://make-magazin.de

Re: Large prints lift off bed

Try to print one singe object, or at least don't put them that close. I would think that this could cause to uneven cooling and leads to warp. Also try a brim?

Also what are your slic3r (?) settings? Cooling?

How do you clean your printbed?

Carsten

I am using the stock slic3r PE settings for PLA

I believe these are them:

I clean the bed with 99% IPA.

So what is the science behind warping? Uneven cooling? Wouldn't bunching your prints together keep things warm? Would a heated enclosure help matters? Or if I just turn up the bed temp? That room is chilly during the day, nobody is up there.

Is there anything published for recommended ambient temperature for each filament type?

Re: Large prints lift off bed

Is there any reason that you are not printing with a brim?

Re: Large prints lift off bed

Jordan, try to set heatbed temperature a bit higher (by 5°C). Warping PLA prints are mostly because of

- bed not absolutely clean

- incorrect first layer

- incorrect temperatures

Re: Large prints lift off bed

Is there any reason that you are not printing with a brim?

That object does not need a brim.

Re: Large prints lift off bed

Is there any reason that you are not printing with a brim?

because i didn't know to..?

Re: Large prints lift off bed

Jordan, try to set heatbed temperature a bit higher (by 5°C). Warping PLA prints are mostly because of

- bed not absolutely clean

- incorrect first layer

- incorrect temperatures

My first layer is tight... I tuned the live z really well

My bed I thought was pretty clean, I clean it before every print. Should I be using acetone or something stronger?

I will try turning up the temp.

Re: Large prints lift off bed

I would say adding a brim (checkbox in the slicer software) to your print should be the next step. Go with 8mm just to make sure.

Re: Large prints lift off bed

I print PLA at 230C nozzle and 65C bed.

I find that acetone cleaning the PEI sheet works better than IPA. A scubbing with super-fine steel wool is also helpful.

Regarding the science of warping; A lot has been written about it, much good much nonsense. Well, I have not really searched for a scientific analysis of warping, just googling reports and tips from 3D printing enthusiasts.

My understanding of warping is incomplete and evolving, this is the '3 words or less' summary so far:

1) deposited hot layers shrink as they cool

2) Next hot layer gets deposited on already shrunk cooler layers, bonds with them before shrinking, then very forcefully bends the lower layers as it also shrinks a little bit.

3) each further layer adds a bit of warping, so you end up with a concave vertical edge and an upward curling bottom layer.

4) More material, more warping force.

The way to reduce warping is to keep the part a bit lower than it's glass transition temperature, look up 'annealing'.

Practically, with a home 3D printer without heated chamber, you need to design parts so that they can warp without affecting the function of the part.

PLA is the easiest material to print wrt warping, you should be able to work this out for PLA.

Re: Large prints lift off bed

If you want to succeed printing large objects in a cold room, then you need to build an enclosure.

You may also be able to print a sacrificial enclosure around the parts you are printing, a thin wall to stop drafts and keep temperatures higher.

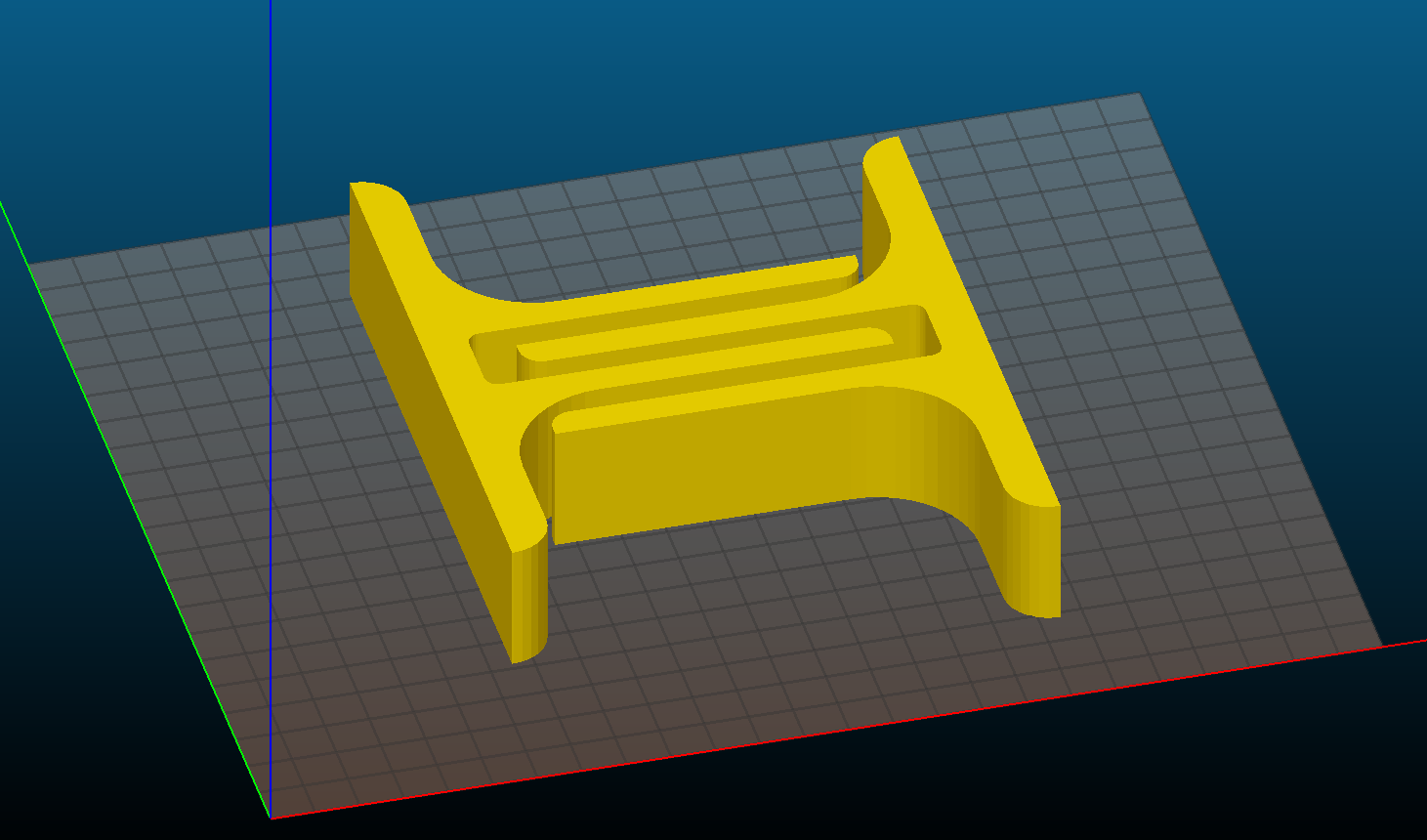

I think the shape of your parts and the way they are arranged might be funnelling the wind from the nozzle cooling fan into the centre of the bed, where you see the worst warping. most of the time, warping is worse on the outside of the bed, where cooler air hits the part.

You can use smoke from an incense stick to make airflows around your print bed visible, it may be an eye opener.

Re: Large prints lift off bed

If you want to succeed printing large objects in a cold room, then you need to build an enclosure.

You may also be able to print a sacrificial enclosure around the parts you are printing, a thin wall to stop drafts and keep temperatures higher.

I think the shape of your parts and the way they are arranged might be funnelling the wind from the nozzle cooling fan into the centre of the bed, where you see the worst warping. most of the time, warping is worse on the outside of the bed, where cooler air hits the part.

You can use smoke from an incense stick to make airflows around your print bed visible, it may be an eye opener.

I think your right about the part shapes.The other part warped too but only in the middle where it was thin. I will have to be more careful about part placement.

Re: Large prints lift off bed

Hi Folks, I have just completed this print, it's a Moneybox with separate divisions for British 1p, 2p, 5p, 10p, 20p, 50p £1 and £2 Coins

It's close to the maximum size for the original prusa i3.

I had difficulty getting it to stick in the first place, perhaps I should have used a brim as well...

in the end I laid down a thick first layer with a bed temperature of 55C then adjusted the bed layer to 65C for the remaining 34 hours...

everything went well until about 20mm from the end, when there was a couple of layer shifts... (Printer was on quiet mode... )

switching to full power mode, actually made the surface finish worse at the higher layers (the Y axis was 'trembling' with movements ) this trembling was worsened by print speed and high power mode.

there is a little play in the bearings which normally doesn't seem to cause issues at lower layers but is probably the cause for the layer shifts towards the end of the print...

this print took about 1.5Kg of filament, so I am not starting again.

from the top of the model, you can see there was a little disfiguration but it didn't pull off the heat bed...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Large prints lift off bed

I split the defective parts off the model, and tried to print some repair pieces. when it became obvious that there were other issues. the cold end fan was wavering significantly in speed... and the 'actual' extruder temperature display was changing in a crazy manner...

I guessed that it would be a thermistor problem, and began to replace the thermistor. however the heatblock, thermistor, heater assembly was a bit of a mess. As my second kit had recently arrived, and it had the newer heatblock, I decided to replace the whole extruder, and order replacements for the new printer. I had been putting off the upgrade to 3.0.9 pending the arrival of the multicolour upgrade.

Following the replacement of the extruder, I also upgraded to 3.0.9, to stop those NAG messages!... everything is now back together, and seems to be working well, with the exception of more overshoot / undershoot on the extruder... as I have fitted a silicone boot, I suspect I will have to run a PID update.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Large prints lift off bed

I split the defective parts off the model, and tried to print some repair pieces. when it became obvious that there were other issues. the cold end fan was wavering significantly in speed... and the 'actual' extruder temperature display was changing in a crazy manner...

I guessed that it would be a thermistor problem, and began to replace the thermistor. however the heatblock, thermistor, heater assembly was a bit of a mess. As my second kit had recently arrived, and it had the newer heatblock, I decided to replace the whole extruder, and order replacements for the new printer. I had been putting off the upgrade to 3.0.9 pending the arrival of the multicolour upgrade.

Following the replacement of the extruder, I also upgraded to 3.0.9, to stop those NAG messages!... everything is now back together, and seems to be working well, with the exception of more overshoot / undershoot on the extruder... as I have fitted a silicone boot, I suspect I will have to run a PID update.

regards Joan

That sounds much like my problem, which is multiple broken cables due to printing of large objects. The full X-axis movement, repeated man times due to the full Z-axis use for your object, bends the wires to the maximum twice for each layer. Soon they break where they are bent 90deg, entering the back of the extruder.