Issues with print finish

Hi All

I have an MK3 (upgraded to the MK3S a few months back). I am facing some surface finish problems with my prints, that looks mostly to do with the seem position.

1 : https://drive.google.com/file/d/1FsGTlNdvdqCCtSXetmHNgEeEH0DfbM3k/view

2 : https://drive.google.com/file/d/1FtxC4BruLhurXa2wri3AyqxJPpAql4XU/view

3 : https://drive.google.com/file/d/1FdPYv3KetAVoTwZoeBBHhU-MYToworKV/view

1 -> Checkout the layers. And also the prominent seam positions. (Ignore the stringing for the time being 😊 )

2 -> I changed the seam position setting to "random" and this is what I got. 🙁

3 -> Two prints of the same object, with matching seem positions.

Material : Prusa PLA

Layer height : 0.2mm

Speed : Almost the default "speed" setting.

Retraction : 1.2mm @ 50mm/s.

Anything obvious that I am missing ?

1) Too fast for the small parts ?

2) "Wet" filament ?

3) Will printing outer layer first help ?

Please help.... 😊

RE: Issues with print finish

Looks like over extrusion to me. Please provide the project file so we can verify the PS settings.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Issues with print finish

And post images in the forum so they don't disappear when you delete them - that way future searches will still get to see what you are fighting (and some of us don't touch files hosted outside the forum for safety reasons).

RE: Issues with print finish

Looks like over extrusion to me. Please provide the project file so we can verify the PS settings.

How do I share the configurations ? I tried "File -> Save Project" in PrusaSlicer and got a .3mf file. I tried opening it again, but it did not have the changes I had made.

RE: Issues with print finish

And post images in the forum so they don't disappear when you delete them - that way future searches will still get to see what you are fighting (and some of us don't touch files hosted outside the forum for safety reasons).

Agree. 🙂 I tried attaching the files, but it would let me attach only a single file which is why I put them on my drive.

RE: Issues with print finish

And post images in the forum so they don't disappear when you delete them - that way future searches will still get to see what you are fighting (and some of us don't touch files hosted outside the forum for safety reasons).

PFA the 3mf file. The corresponding print :

RE: Issues with print finish

Linear Advance is not working well with your retraction settings. You may want to do a test and get the K factor adjusted to reduce the blobbing at the seam starts. It also looks like you have some belt wobble or a belt drive gear wiggling a bit: the walls are quite uneven.

I'm curious, what do the parts look like with stock retraction? Why the change from defaults?

RE: Issues with print finish

Hi there,

I own a Prusa MK2.5S and I am experiencing the exact same problems only with PLA!

Ever since my first upgrade from MK2S to MK2.5 I couldn't get the hang of printing PLA any more, all other filaments work fine though. Even Polymaker PC-Max looks better than PLA on my machine!

I've tried variuos things so far:

-different filament manufacturers

-properly calibrated my E-steps as described on Matt's Hub

-calibrated my extrusion multiplier first with the single walled cube as described on Matt's Hub, then realized my top surfaces still showed significant over extrusion... I then calibrated the extrusion multiplier with two cubes without top layers, one with 90% infill one with 100%. A less mathematical method, but this way I got decent extrusion on all surfaces, ASIDE from line start points and corners, therefore:

-I also tuned the k-factor via Matt's method on his Hub and got the best results at around K30 there, but prints with K30 still showed these start blobs.

I then noticed that corners were "dragged" and sometimes perimeters had gaps only directly in the corner.

This of course looked very much like bad linear advance calibration to me, i.e. too much extrusion when accelerating and too little when slowing down.

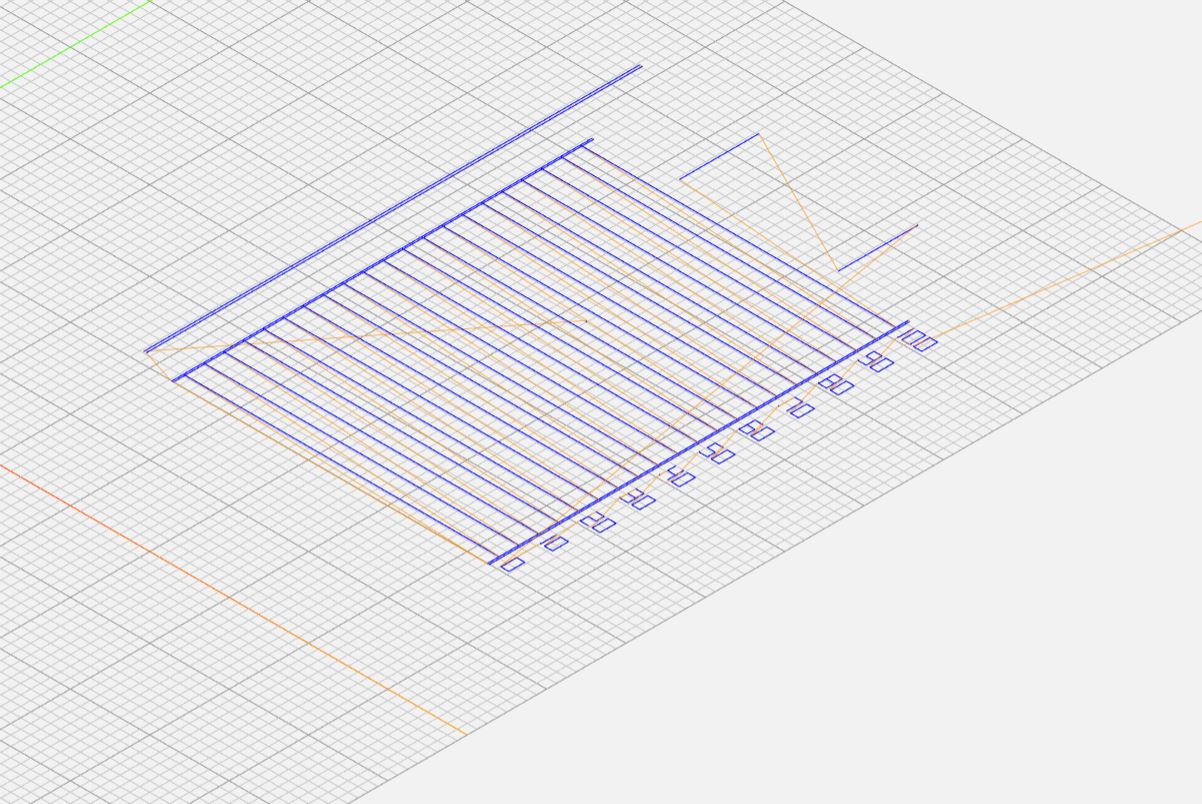

I am now in the process of trying different K-factors on a 25x25x25 test cube. Using K10-increments I am printing with these cubes now and the surface quality has been improving slightly over the course of my test (currently at K100).

The sad part is though that PETG prints look close to perfect on my machine (and there still is a little over extrusion on them, a little stringing etc.), but even with these high K-values PLA prints didn't look great... guess I'll try even more K-values...

Greetings DerBierBaron

RE: Issues with print finish

[...] I am now in the process of trying different K-factors on a 25x25x25 test cube. Using K10-increments I am printing with these cubes now and the surface quality has been improving slightly over the course of my test (currently at K100).

You'll likely find that a 25mm cube is a little small for LA testing. I found about 60mm/s to be the sweet spot for letting the nozzle come up to full speed and do a full slow.

I never found that LA impacts start blobs, but it has a significant impact on corners and z-seams. Here's my 60mm test part increasing LA from the bottom in increments of 5:

RE: Issues with print finish

Here's a link to a test pattern generator. The test is quick, easy, and accurate (aka, easy to read) Takes a couple minutes to print. Homing and mesh level take the most time.

http://marlinfw.org/tools/lin_advance/k-factor.html

RE: Issues with print finish

Here's a MK3 gcode for the LA test ... the code is set to use LA v1.0, not v1.5. If your fw has 1.5, then create a new gcode at the Marlin site.

RE: Issues with print finish

Looks like I have a lot of things to do. 😀

Give me a few days, and I'll get back. Hopefully the thread won't get closed. 😊

Thanks a lot guys.

RE: Issues with print finish

[...] I am now in the process of trying different K-factors on a 25x25x25 test cube. Using K10-increments I am printing with these cubes now and the surface quality has been improving slightly over the course of my test (currently at K100).

You'll likely find that a 25mm cube is a little small for LA testing. I found about 60mm/s to be the sweet spot for letting the nozzle come up to full speed and do a full slow.

I never found that LA impacts start blobs, but it has a significant impact on corners and z-seams. Here's my 60mm test part increasing LA from the bottom in increments of 5:

The way I've calibrated linear advance so far was solely by the method described here:

https://mattshub.com/2017/10/02/linear-advance/

a similar method to the one tim-m30 posted. With this calibration I come out at K29 to be precise.

Here are some pictures of one 25mm² cube with K29 and one with K110

You can clearly see the blobs are mostly gone, altough the surface still looks "inconsistent".

I get better surfaces on other materials though... I'll print one in PETG to show what I mean.

Greetings DerBierBaron

RE: Issues with print finish

Linear Advance is not working well with your retraction settings. You may want to do a test and get the K factor adjusted to reduce the blobbing at the seam starts. It also looks like you have some belt wobble or a belt drive gear wiggling a bit: the walls are quite uneven.

I'm curious, what do the parts look like with stock retraction? Why the change from defaults?

Going to adjust the K factor now. And what exactly do you mean by belt/drive gear wobble ? Do you mean that the belt is moving laterally ?

And I changed the retraction settings to fix some stringing issues I was facing. Maybe after the LA test, I will try going to the default retraction settings.

RE: Issues with print finish

The way I've calibrated linear advance so far was solely by the method described here:

You mentioned doing testing and developing a test part. I was recommending a larger size than the 25mm cube. You'll notice the runs on that calibration print are longer.

RE: Issues with print finish

The way I've calibrated linear advance so far was solely by the method described here:

You mentioned doing testing and developing a test part. I was recommending a larger size than the 25mm cube. You'll notice the runs on that calibration print are longer.

I believe I get what you mean, but the 25mm³ cubes were just meant as a test and not a real calibration. I feel I've not yet gotten a real handle on the roots of my problems yet. What I mean by that is that I can't wrap my head around the fact that every single filament works fine on my MK2.5S, even semi-flex, PC-Max, PolyMide CoPA etc. but PLA sticks out as the bad boy 😎

The Marlin type calibration has stretches of longer then 100mm extrusion, so at least the effect for line width should be easily seen there and I got K29 out of that test (this is what I consider a calibration result). Yet using K29 even with large prints before (like the overhang test here: https://www.thingiverse.com/thing:40382 ) resulted in these zitty/blobby surfaces plus inconsistent surfaces.

I then redid all calibrations as described above and still no change in surface quality... then came the idea with linear advance as the cause of the problem. Yet I still wasn't sure whether I could really calibrate not knowing, if linear advance was the sole culprit. Granted, if linear advance is calibrated properly other issues might become more predictable, but my old MK2S printed really great in PLA and back then there was no linear advance in the firmware. So I did this test only to get a view on the effects of different K-values quick and dirty so to speak.

You might be (most definately actually) true that properly calibrating linear advance needs a bigger test object. I think though that the effects should become visible in smaller prints as well, just way less pronounced.

What's more I have some more news that I can't figure out now: I also tried using the stock Prusa profiles again. The profiles I've been using were modified since the time I bought my kit back in 2016 and thus far always ported between releases of Slic3r, throughout the time it was further called Slic3R PE and now to Prusaslicer 2.1. This time I used the stock Prusa PLA profile, also with the stock MK2.5S printer profile and the 0.15mm settings with linear advance, I only changed the seam to random (to compare to my other prints).

The result is a test cube very similar to the K110 one shown above, but the gcode has K30 written in it by Prusaslicer! The only difference is a miniature blob at the end point of the outer perimeter lines, and inconsistent extrusion... shown below

I honestly don't get it but I guess the best course of action should be to go from there and discard my old profile. Thoughts?

Greetings DerBierBaron

P.S.: Any thoughts on the inconsistency issue? I've read about the 602 issue a lot and have seen the video Prusa released but as all other filaments work fine for me, why does only PLA look inconsistent?