Different Nozzle Problems

Hi All,

This is my first post so forgive if its already out there.

Recently I have purchased a 0.6mm nozzle as i wanted to print faster and interest in using wood filaments. I changed the nozzle to the 0.6 as per instructions and also updated slicer to suit the nozzle change settings.

Unfortunately I can't get anything to print at all apart from the brim, and the first layer calibration, switch back to the 0.4 and great prints, am I completely missing something guys?

Any help would be massively appreciated

Thanks in advance,

Colin

RE: Different Nozzle Problems

Hi Colin?

what happens if you try to print a simple object?

I have enclosed a Z IP file containing the STL, 3MF and Gcode files for the sample print, could you try and print the gcode with PLA flament and let us see pictures of the first layer and final picture, if it fails, the failure picture, please...

regards Joan

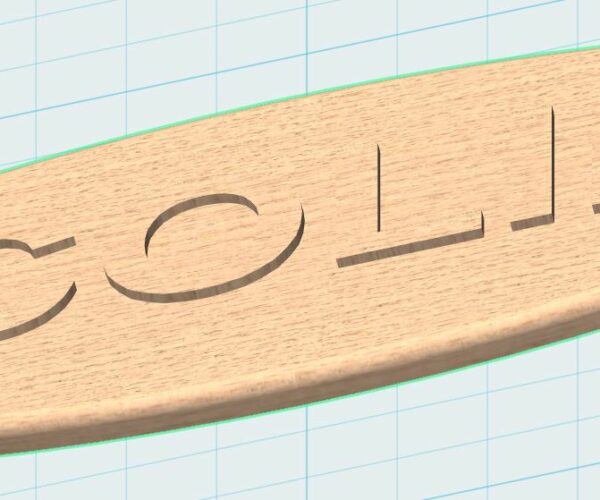

p.s. it will not magically become woodgrain... i was simply trying to get a contrast to show the lettering! 🙂

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Different Nozzle Problems

@joantabb

Hi Joan,

Thank you very much.

Please find attached the relevant pic's, It would appear simple designs are okay also tried a benchy which seems okay.

I have then also printed the design I want to print in wood, in PLA which was fine 🙂

This seems really strange but after printing the file you kindly did for me it appears to printing fine on the 0.6 , although I do have 1 more question if its okay.

I have a wooden filament and have tried printing with these terrible results, unfortunately I don't really print enough to be savvy with what the issues are. I was wondering if you could give me your opinion?

Thanks again.

Regards

RE: Different Nozzle Problems

I tend to print wood materials at the top of their suggested temp range so for that filaprint wood filament make sure your filament profile has had its temperature changed to 230-235 degrees.

Also you could try printing off a live z square with that filament to see if the live z needs adjusting for that filament/nozzle combination.

RE: Different Nozzle Problems

Hi Colin,

the wood filament model in the last picture seems to have self destructed during the first layer.

It is very difficult to see what is going on, and what is not working.

can we see the bottom layer of your successful models. please

I don't recall putting a brim on the oval 'COLIN' model, did you need to add on to improve adhesion?

I am guessing that adhesion is one of your problems....

What I do, with PLA, is to take the build plate into the kitchen, and run the hot water until it is nice and hot, then using a NEW dishwash sponge and some liquid dishwash soap, I scrub the whole build plate surface, Up and down, Across left to right, diagonally and in circles to ensure that every square centimetre has been covered, and then rinse the whole surface off with hot clean water,

I then dry the whole surface with clean dry, untreated paper towel, AT ALL TIMES, making sure that I handle the build plate by the edges.

once clean, I return the build plate to the printer.

I make sure that the printer is doing 7x7 mesh bed levelling (Available via LCD menu on the later Prusa's...

and I do a live Z adjustment.... (First layer adjustment. ) Now the built in Prusa first layer adjustment is intended for 0.4mm nozzles, so it is useless for a 0.6mm printer. also the 'Life adjust 'Z' My way' files are also intended for 0.4mm nozzles, so you really need something sliced for 0.6mm nozzle to make these adjustments....

So what I suggest is to simply use a simple model, such as the Oval 'COLIN' logo, and print the first layer, then stop the print...

If the plastic extrusions look like individual lines (Like spaghetti) then your live Z is too high, increase the size of the live Z negative value

If the plastic extrusions look lumpy, ripply or rough then your live Z is too low, decrease the size of the live Z negative value

and

If the plastic extrusions look like nice and smooth with no loose strings, it should peel off as a single sheet, then you have the live Z just about right...

once live Z is good. clean the build plate and try a new model...

when you slice the model, you could slow down the first layer speed (it's an advanced setting in the 'Printer Sttings >Speed' menu)

Save the Gcode to the SD card

then print the model and see what happens.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Different Nozzle Problems

@joantabb

Hi Joan,

Thank you again for your detailed response.

The problem I am having is at the start of a new move it seems to be lifts at the beginning of it thus next time around pulling it up. If the move is continuous then it is absolutely fine so obviously the more details the worse it is.

I think its possibly down to temp and retraction speed but I'm just guessing from what other user are suffering and their solutions. Unfortunately I'm not completely savvy on which value to move and how much to retract by and so on, I have used the slicer setting and also the manufacture setting with no avail.

Just a thought, Is it worth me putting down a very thin base with the lettering on top so this would be able to just remove manually afterwards?

Thanks Again 😀

RE: Different Nozzle Problems

have you tried my suggested build plate clean and Live Z calibration followed by a test print suggestion, you may be surprised!

I use 70C on the bed for PLA.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Different Nozzle Problems

Any filled filament is going to be prone to jams. The additives like to get stuck in the nozzle...

Until you get some experience with your .6 mm nozzle, I would stick to plain filaments.

Also, when you switch from filled anything to not filled anything, do a cold pull and some cleaning filament.

(I only use cleaning filament - since I am an awful cold-puller. But I still recommend it.)

RE: Different Nozzle Problems

Thanks Rob and joan,

I will give them ideas a go today and see what happens.

I have read that colorfabb woodfill can run with a 0.4 nozzle, so I may switch back and see what happen if the other ideas don't work.

I did print something basic and it was to bad, see attached it just seems when it comes to a new move so i'm thinking its a oozing issue hence me trying to alter retraction values.

RE: Different Nozzle Problems

Hi Colin,

on the background of the name tag,

you seem to have slight roughness in the surface that could be either, a visual artefact caused by printing fibrous material , or could be slight over extrusion, if you still have the nozzle in the printer it might be worthwhile reprinting the model at say 90% flow rate, and see if you get an improvment

'Flow rate ' is a way of adjusting the amount of filament extruded inside the printer firmware, rather than re-slicing with a lower extrusion multiplier.

note Prusa slicer already modifies flow rate for all layer heights above 0.075mm, using the following line in the Custom Gcode section...

M221 S{if layer_height<0.075}100{else}95{endif}

which means that the model you printed was almost certainly printed at a flow rate of 95%, therefore if you want to further reduce the flow rate, you need to go below 95%...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK