drooping fan shield

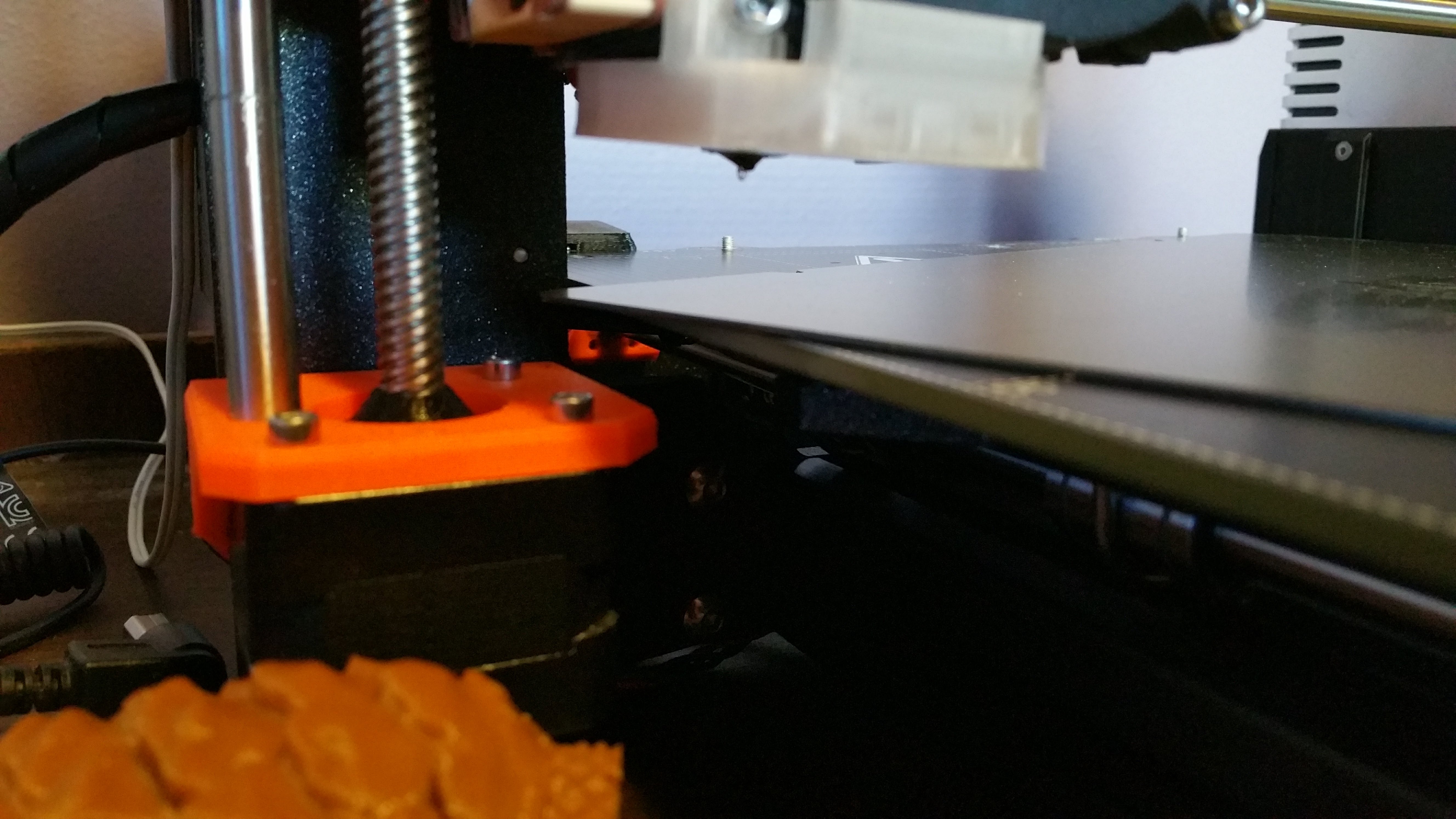

I have been printing some high temp items, Polycarbonate (270c nozzle temp) tons of abs including a 24 hr print at 255c and some pet-g at 240-260 and today i started up an abs print again and heard something dragging on the print. it appears the fan shroud has deformed enough from the heat to have major droop. The circled spots on the pictures correspond to where the heater cartridge is and they are both a different color and the points where the most droop is occurring

anyone else seeing this?

Re: drooping fan shield

What amount of cooling did you have active during these prints?

Re: drooping fan shield

Mine did the same thing but I didn't notice until it had ripped a part from the bed and really deformed it. I had been printing a lot of abs as well and had my cooling fan off. Had to print another one.

Re: drooping fan shield

So what would the solution to this be? print one from a higher temp handling material like nylon?

Re: drooping fan shield

What amount of cooling did you have active during these prints?

very minimal, abs and PC don't really use fan.

So what would the solution to this be? print one from a higher temp handling material like nylon?

well pet-g is not the answer, 30 minutes into an abs print it is already drooping. I have one printed out of PC that i will try next.

i wonder if this shouldn't be metal

Re: drooping fan shield

What amount of cooling did you have active during these prints?

very minimal, abs and PC don't really use fan.

If you're not using it very much I'd consider removing it or raplacing with a more minimal design for ABS and PC prints. It's only held on with one screw anyway so removing is no big deal.

So what would the solution to this be? print one from a higher temp handling material like nylon?

One could attempt 'recrystalized' PLA that has been baked at 100C for an hour. These have been shown to stand temperatures up to and beyond 140C without softening.

Re: drooping fan shield

Yup, predicted this one and told Joseph to correct before production shipments. Guess nothing was done.

Do you have a sock? Highly recommended.

Just for $h!t$ and giggles I specified alternatives.

Melt estimate and costing is purely material (Shapeways processing fees minus shipping).

MK2S kit owner since 8/15/2017

Re: drooping fan shield

Yup, predicted this one and told Joseph to correct before production shipments. Guess nothing was done.

Do you have a sock? Highly recommended.

Just for $h!t$ and giggles I specified alternatives.

Melt estimate and costing is purely material (Shapeways processing fees minus shipping).

thought all printed parts were already petg? seems like sitting a half inch away from a 290c nozzle would deform just about anything without some cooling.

Re: drooping fan shield

MK2.5 ships with ABS sadly.

Currently still have ABS parts on MK2S, slowly transitioning to HT (ColorFabb's high temp PETG as in table). Used to run 11% fan as insurance in long prints. Designed my models assuming curl and worked out well so far. I've heard tale of some removing the fan and nozzle to reduce weight when printing non-cool filaments like ABS and PETG but I swap materials too often for that to be convenient.

Sock is the quickest solution. Heater recal may be good to do as a precaution (heard not needed). Silicone insulates, meaning much less radiant heat to surrounding thermo-plastic parts. You will have to watch retractions though as brake clogs are more likely with sock. I run LA with low retraction and haven't had a clog or spider's nest yet with PETG. Thank you for LA Prusa!

MK2S kit owner since 8/15/2017

Re: drooping fan shield

MK2.5 ships with ABS sadly.

Currently still have ABS parts on MK2S, slowly transitioning to HT (ColorFabb's high temp PETG as in table). Used to run 11% fan as insurance in long prints. Designed my models assuming curl and worked out well so far. I've heard tale of some removing the fan and nozzle to reduce weight when printing non-cool filaments like ABS and PETG but I swap materials too often for that to be convenient.

Sock is the quickest solution. Heater recal may be good to do as a precaution (heard not needed). Silicone insulates, meaning much less radiant heat to surrounding thermo-plastic parts. You will have to watch retractions though as brake clogs are more likely with sock. I run LA with low retraction and haven't had a clog or spider's nest yet with PETG. Thank you for LA Prusa!

my printer does have a sock, and have since i got it Dec 18. the place the shroud deforms is where the heater cartridge ends are sticking out of the block and the sock

Re: drooping fan shield

Yup, predicted this one and told Joseph to correct before production shipments. Guess nothing was done.

Do you have a sock? Highly recommended.

Just for $h!t$ and giggles I specified alternatives.

Melt estimate and costing is purely material (Shapeways processing fees minus shipping).

i have printed a PC shroud so that will be up next. I can't imagine given the proximity that anything but metal wouldn't sag.

Re: drooping fan shield

thought all printed parts were already petg? seems like sitting a half inch away from a 290c nozzle would deform just about anything without some cooling.

i believe the part cooling fan shroud is the only abs part. everything else is pet-g

Re: drooping fan shield

I got drooping with sock as well. I know before the sock I had scorching (plastic turned black) so you are better off than not. That doesn't fix the issue though. I'm of the opinion that the MK3 nozzle design was incomplete as is. And since I haven't seen any bulletins officially suggesting removal of nozzle while printing fan-off G-code, the nozzle should be designed to survive to max sustainable temperature of 295°C without airflow.

A better nozzle design would:

I have an MK2S and designed a hybrid nozzle based on MK3. I was struggling with the stock MK2 design and thought they've done better engineering with MK3's. Seems to not be any better for hot-and-idle scenarios than MK2's so I designed my own that so far is holding up well during 4-8 hour prints in these conditions.

Aside from PC, I don't think any material will help the stock nozzle's shortcomings for idle-hot prints. Might be time to go hunting for or designing a better MK3 part for yourself. Sorry.

BTW; my nozzle is ABS.

MK2S kit owner since 8/15/2017

Re: drooping fan shield

I too got a drooping fan shroud (black) that resulted in a couple of prints got shoveled around and plastics build up on the nozzle and fan.

Tested the shroud with Aceton, no reaction at all.

So probably it was PETG.

Printed a new one in ABS, and it seem to hold fine after 15 h of printing.

Silicone socks seems like a good idea.

I noticed that there are two variants:

https://e3d-online.com/v6-socks-pro-pack-of-3

https://e3d-online.com/v6-sock-3pack

Which one of them works best?

Re: drooping fan shield

Silicone socks seems like a good idea.

I noticed that there are two variants:

https://e3d-online.com/v6-socks-pro-pack-of-3

https://e3d-online.com/v6-sock-3pack

Which one of them works best?

The 'Pro' is supposed to be the legacy version and comes with 3 different sized nozzle openings. So in worst case you only get one sock in a pack of 3 that'll fit perfectly. But in any case it has better coverage than the regular version.

The 'Regular' version is the newest with a bigger hole for the entire nozzle to poke through, so nozzle size down't matter and all 3 in the pack are the same. The regular is also supposed to be a bit more slim than the pro.

Personally I go for the pro, even though it's not perfect it keeps all of that juicy heat inside the block and nozzle where it belongs.

Re: drooping fan shield

Thanks.

At that little cost I think I' ll get them both then.

Re: drooping fan shield

I too got a drooping fan shroud (black) that resulted in a couple of prints got shoveled around and plastics build up on the nozzle and fan.

Tested the shroud with Aceton, no reaction at all.

So probably it was PETG.

Printed a new one in ABS, and it seem to hold fine after 15 h of printing.

Silicone socks seems like a good idea.

I noticed that there are two variants:

https://e3d-online.com/v6-socks-pro-pack-of-3

https://e3d-online.com/v6-sock-3pack

Which one of them works best?

the clearances are tight, i do not think the pro will fit. and if it does, out of 3 only one will fit your 0.4 nozzle the other two would interfere with the filament flow. especially since these are consumables, after some time of high heat the silicone degrades and gets brittle and you have to replace

Re: drooping fan shield

Yup, predicted this one and told Joseph to correct before production shipments. Guess nothing was done.

Do you have a sock? Highly recommended.

Just for $h!t$ and giggles I specified alternatives.

Melt estimate and costing is purely material (Shapeways processing fees minus shipping).

PC seems to be a good alternate. I did a 6 hr abs print first and then 1:30hr pc print and no drooping at all. and if you look at the proximity to the heater it is crazy close in this remix shroud. Not sure how this will stand up to nylon temps but i will eventually find out.

for anyone wondering it is the v10 shroud here, and i have swapped back to a PC version of the original prusa shroud.

https://www.thingiverse.com/thing:272054

Re: drooping fan shield

I tweaked the Prusa shroud a bit to have smoother transitions and it's what I use. I won't say it's any better or worse as I'm really new to 3d printing and only had my printer a few days.

Link to stl...

https://drive.google.com/open?id=1WqdEwn2Ssu9XTDlv8IGnyO2Nh5iCj5oY

Re: drooping fan shield

Link to stl...

https://drive.google.com/open?id=1WqdEwn2Ssu9XTDlv8IGnyO2Nh5iCj5oY

put it on thingiverse, that way everyone can see it 😀