Re: Flexion Extruder Prusa Mk2S

Hello, I have done all steps, but it seems that the flexionstruder is too tight on the filament. When I try to load a filament , the extruder stepper motor does not have sufficient torque to push it. Even when I try to loose it does not work. Maybe there is something I am missing on how to adjust pressure on the filament. I am planning to increase stepper motor current in the firmware to compensate for higher pressure, but I would like to know if anyone have any suggestions to my problem where I don't need to modify current.

Thank you for your help!

Re: Flexion Extruder Prusa Mk2S

Hey Alex,

I just finished with single HT extruder mount using metacollin's model for my MK3. I've been having issues printing ANYTHING due to X axis length calibration failures. I can't print at all!!! Was that an issue for you?

I mounted with extruder motor wiring facing upright but otherwise I can't see *any* variation in my steps from Diabase or otherwise. How did you get yours to work?

Regarding loading, I use 2 for TPU which is slightly more than what diabase had on their card and their printing tips website/youtube link.

Update: TL;DR my post https://shop.prusa3d.com/forum/others-archive--f66/self-test-error-x-axis-length-t13327-s10.html : Use a paper under the PINDA height adjust process when moving the extruder (Step 9, Preflight). Rotate the threaded rods down until it contacts the paper and prevents it from sliding. Then raise it just a little bit so it slides without much/any resistance. Repeat for the right side. Move to the center and use a paper on the bed when also using the PINDA sensor adjustment with the zip tie.

Also consider the tension on the belts, try for 250 (lower number -> tighter). Getting belt tension down to 260 or 250 would be ideal, just dont break something. Support->Belt status. The numbers should be lower and ideally 250 for each. A higher value = looser belts. I didnt change the belt tension (mine were too loose at 270 and 310). Good steps that describe that are here ( https://manual.prusa3d.com/Guide/4.+Z-a ... g=en#s9981 and Y axis belt https://manual.prusa3d.com/Guide/2.+Y-a ... g=en#s8225). Reportedly the Support->Belt status values update after passing the self test.

See the rest of the discussion and the full thread at: https://shop.prusa3d.com/forum/others-archive--f66/self-test-error-x-axis-length-t13327-s10.html

Re: Flexion Extruder Prusa Mk2S

Hello Nevin,

I did not have this particular issue. When you do this calibration, does the extruder motor wire get stuck between the X axis Back plate and the orange pieces that hold the 2 giding rods ?

I have now done a couple of prints with the flexion extruder now with my Prusa i3 Mk3. I have done quite high quality part both with PLA and TPU. The main issue I had was to adjust extrusion multiplier. At first ,I thought that I would need to reduce the extrusion multiplier because it is suppose to push filament better with less slipping. However, I end up putting a much higher value than before, like 1.4-1.5 for PLA and 1.8 for TPU in order to get good prints. I do not understand why I need to put so much higher value, but the flexion extruder works well with those values

If you successfully done printing by now I would like to know what extrusion multiplier you are using

Thanks

Re: Flexion Extruder Prusa Mk2S

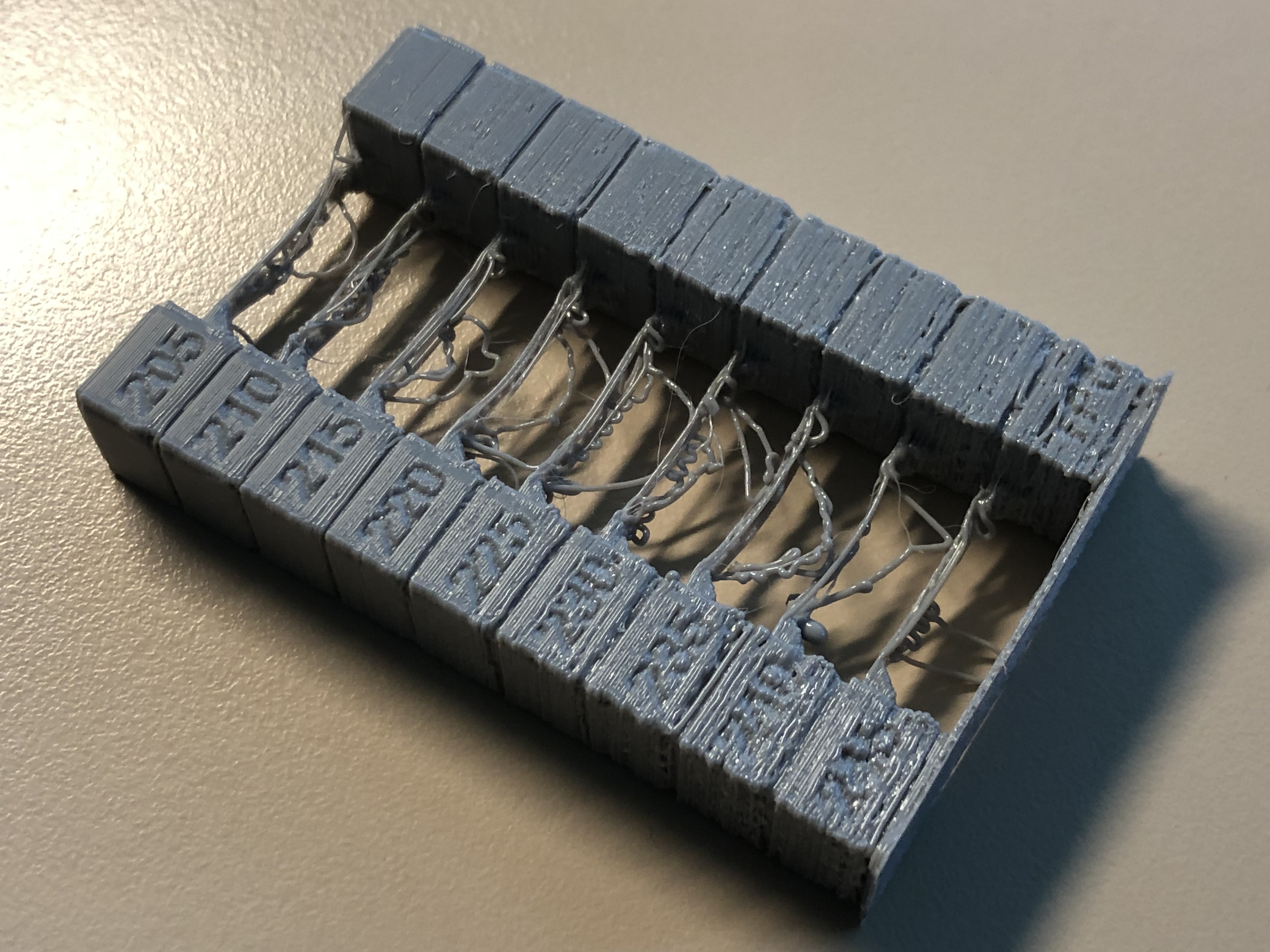

Image 1: Sainsmart TPU after removing supports. 3 hr print, 15min time to remove tpu supports.

Image 2: Sainsmart TPU immediately post print. Existing TPU supports visualized. Simplify3D sliced. 3 hr print.

Image 3: Temperature tower for Ninjaflex cheetah tpu.

No, I dont feel that I had that issue with a wire getting stuck at all!

I started using ninjaflex cheetah tpu 1.75 and had to decrease my extrusion muliplier to 0.3 and 0.4. Otherwise my prints were very globby and looked like absolute trash. Once I dropped my extrusion, it looked fantastic.

I have since started using Sainsmart tpu 1.75 and since had to increase my extrusion to 0.9 or so. I wasnt able to use sainsmart tpu at all on my prusa due to it always jamming on my prusa rc3 extruder.

My prints have been looking fantastic. My only issue is that I cant do non-tpu supports. I am really hoping for brain3d quality tpu prints and it seems that unless I do supports for overhanging segments of the model, sagging of unsupported sections degrades the appearance of the model.

Right now Im toying with looking at: A) a second printer to fit a dual HT onto, B) seeing if it’s possible to use the prusa MMU 2.x with this extruder, or C) trying to takea crack at designing my own dual HT extruder mount.

Re: Flexion Extruder Prusa Mk2S

Oh.....and FYI, there is a NEW model by metacollin that us more up to date and better suited for mk3 and RC3. It csn use the existing hotend assembly and seems to not have some of the rising temperature issues as the previous model. However, it looks like it would be much harder to modify for a dual HT extruder assembly. That being the case, Id happily would have done this version instead!!!

https://www.thingiverse.com/thing:3207190

I was chatting about it online, too. Please reference this thread:

https://reddit.com/r/prusa3d/comments/a9x551/_/ecopol3/?context=1