Re: alternative nozzle cooling

looks quite impressive.... black, bold, mean .... anything to consider with printing the black poly-carbonate stuff ?

btw. did you prepare your design for 2 LEDs, so that the borehole camera could deliver good pictures with a decent contrast ?

dem inscheniör is' nix zu schwör...

Re: alternative nozzle cooling

very nice & bright !

did you measure the temperature of the little LED/pcb ?

and yes, it might be a problem that the cable is located directly underneath the hotend. maybe you can use some kapton tape to insulate it from the heat.

btw. i'm thinking about powering the LED illumination by the supply for the extruder fan, which starts at 50°C anyway...

dem inscheniör is' nix zu schwör...

Re: alternative nozzle cooling

This is probably not a problem. Each newer fan has 4 pins. Not all are connected.

Connect + to permanent 12V, - to minus, solder an wire (blue line) and connect to the Rambo Fan out (former black wire) :

Unbenannt.JPG

I have not tested it on this fan so far. But I'm sure it will work there too.

Update : Modified and tested now 😀

P1040675.jpg

But, you have to invert the PWM-signal on the output via the M106 P0 I0 Sxxx gcode.

Thomas

Can you explain the M106 code further and what I need to do? I have this fan but need to print the new holder. Trying to finetune the printer first to get a good fit.

Re: alternative nozzle cooling

The temperature at the LED-PCB isn't worth mentioning. I draw it with about 80mA, just getting a little bit warm.

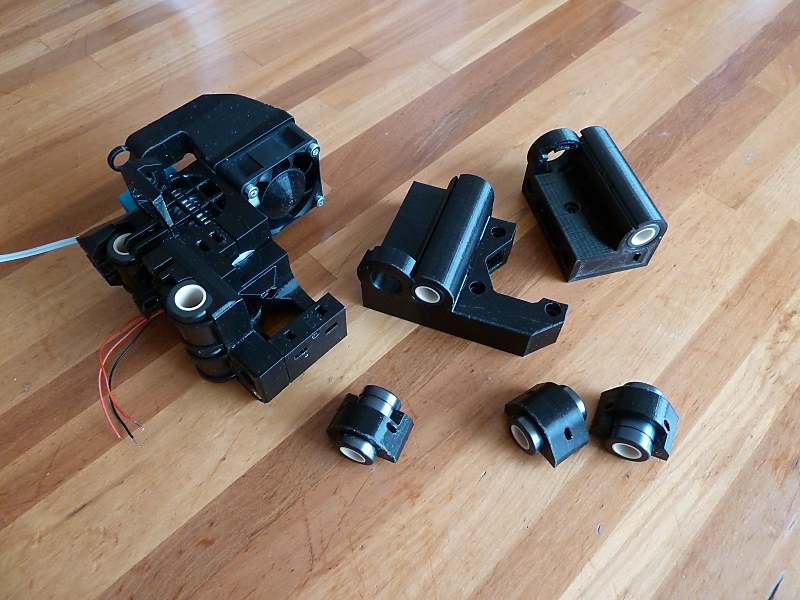

Please be patient. Will assemble the parts in a couple of days if I have printed all parts in PC.

For the fan. I will NOT use the inverted PWM gcode for future because it has some disadvantages. I will build up an small breakout PCB which inverts the PWM by using an MOSFET. This has the advantage that you did not change anything on the code. And secondary I need a power supply for the LED on the fan shroud.

Love this material : PC, very smooth and easy to print. It's very strong and withstand 110°C.

Thomas

Re: alternative nozzle cooling

Love this material : PC, very smooth and easy to print. It's very strong and withstand 110°C.

Looks good, what's the exact brand?

Re: alternative nozzle cooling

https://www.filamentworld.de/shop/filament-3d-drucker/pc-filament-1-75-mm-schwarz/

I use the PC plus because PC max has a litte bit less strength.

Thomas

Re: alternative nozzle cooling

https://www.filamentworld.de/shop/filament-3d-drucker/pc-filament-1-75-mm-schwarz/

I use the PC plus because PC max has a litte bit less strength.

Thomas

quite expensive stuff, more than the PlaTec from TwoBears...

- schluck -

dem inscheniör is' nix zu schwör...

Re: alternative nozzle cooling

Yes 🙁

You can use PC from rigid.ink too, but it's only available in transparent :

https://rigid.ink/products/polycarbonate-1-75-mm-0-03-mm-tolerance?variant=3537082305

And has more printing and heatbed temperature. I tested it with 295°/110°. The heatbed is not afraid of this high temperature, the PEI came lose. And sometimes I have an hotend overtemperature error.

Thomas

Re: alternative nozzle cooling

i'll give the pc plus a go.

dem inscheniör is' nix zu schwör...

Re: alternative nozzle cooling

A orange colored PC would be fine ...

:ugeek:

Thomas

Re: alternative nozzle cooling

How were the results with this set up? I still have the fans but need to print this off and figure out how to wire up fan to have variable speeds.

Re: alternative nozzle cooling

Stay tuned !

Got my igus rods on Saturday. Will disassemble the printer in a few days and reassemble it with the new extruder/fan.

See posts here http://shop.prusa3d.com/forum/original-prusa-i3-mk2-f23/when-is-the-fan-supposed-to-start--t4779.html#p34866 and here http://shop.prusa3d.com/forum/improvements-f14/prusa-blackpc-edition-t4723.html

Thomas

Re: alternative nozzle cooling

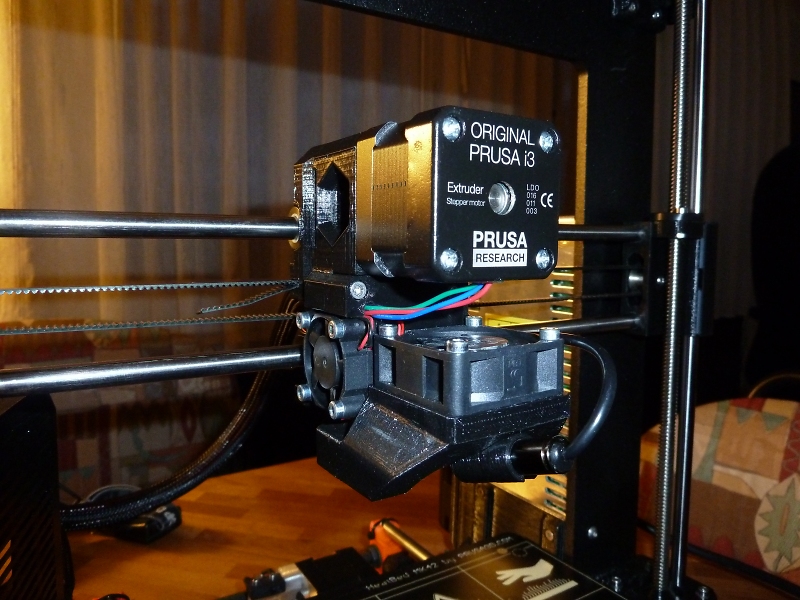

Updated my printer to the new extruder 😀

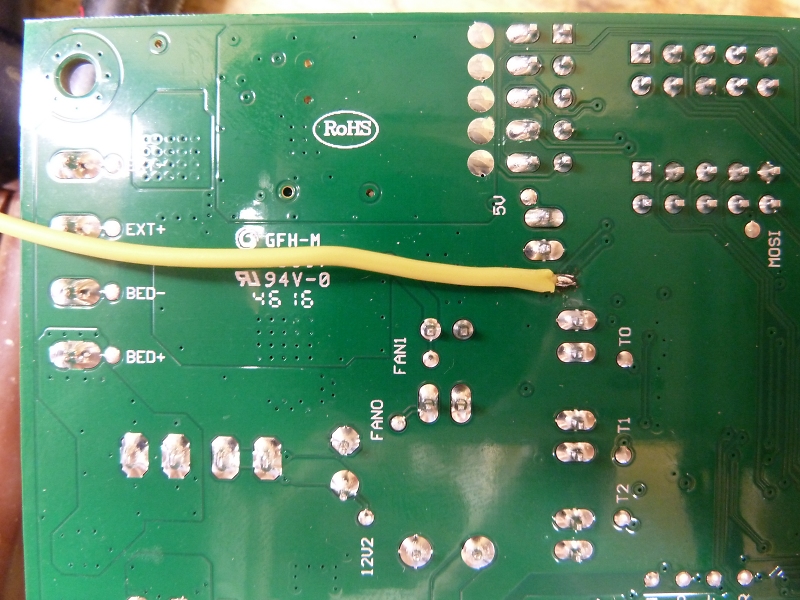

Some steps to do with the electronic for the new fan. This fan is PWM-controlled and will not work as designed with the original Prusa setup. But no problem, it can be fixed relative easy.

First we have to solder the 3rd wire for the PWM signal on the fan as described in an earlier post here.

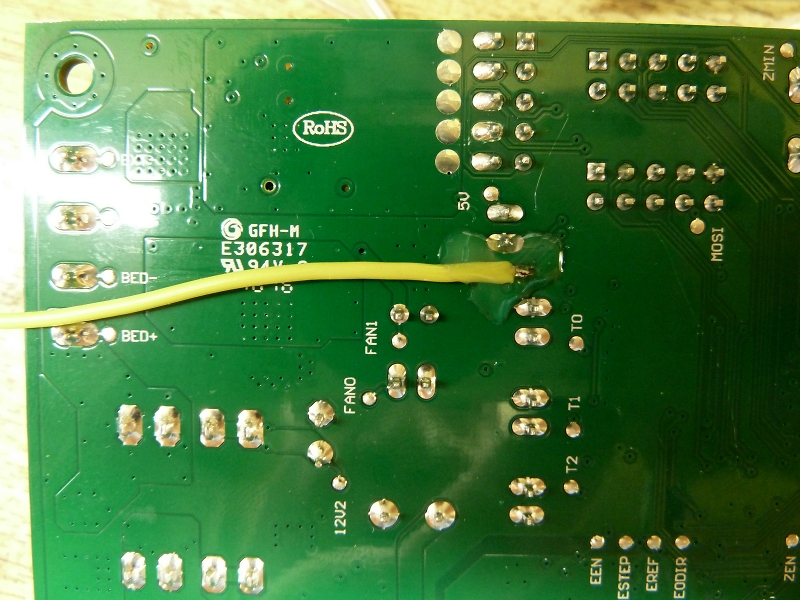

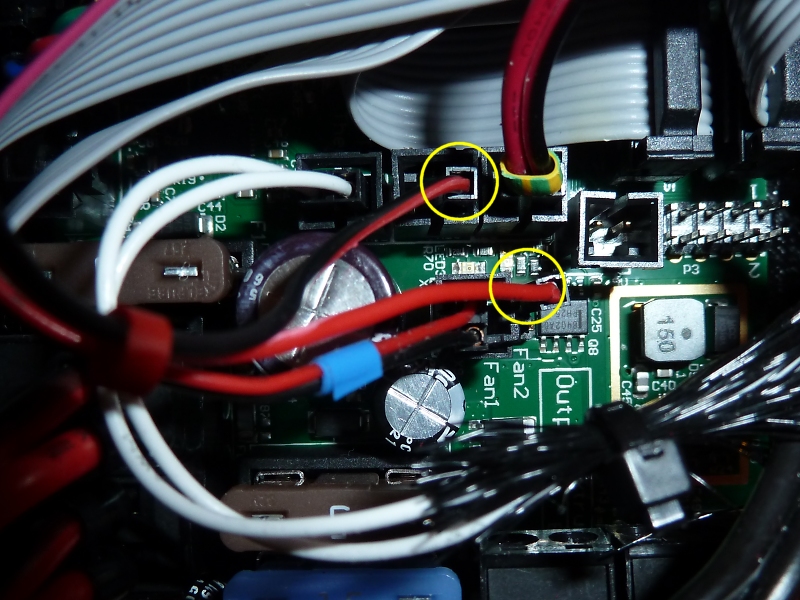

This 3rd wire goes to the MCU (Fan-1) at the Rambo board (yellow marked).

Unfortunately there is no pin to connect, so we have to make an junction for the cable yourself. Search for the connection of R9/R16 on the PCB. There goes an wire to the Atmel through 2 vias (yellow marked).

Remove the solder-stop with an sharp scalpel from one via from the bottom side of the PCB. Be careful to only scrape the via and no other layers. And also be very carefully to do not remove the copper from the PCB, otherwise you destroy your Rambo ! Solder an wire on this blank via.

Re: alternative nozzle cooling

Secure the cable with some hot glue.

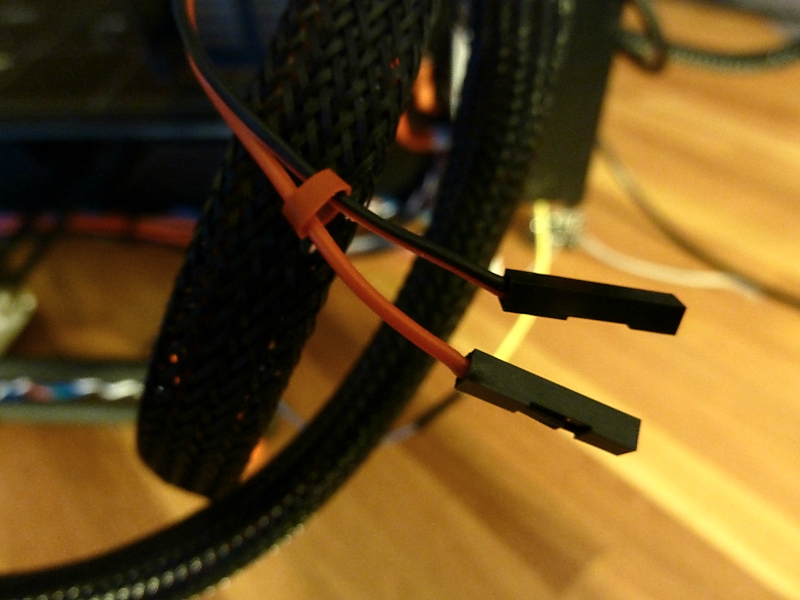

Next step is the power supply for the fan. We cannot use the original pins for fan 2 anymore because the new fan has to be powered permanent. So, split the fan cable with the red ring into 2 different wires. I used the original cable and fitted it on the new fan.

The red wire will be plugged into the original position as before and the black wire goes to the T1 pin near to the T0 plug. See picture below, as marked in yellow.

Re: alternative nozzle cooling

That's all 😉

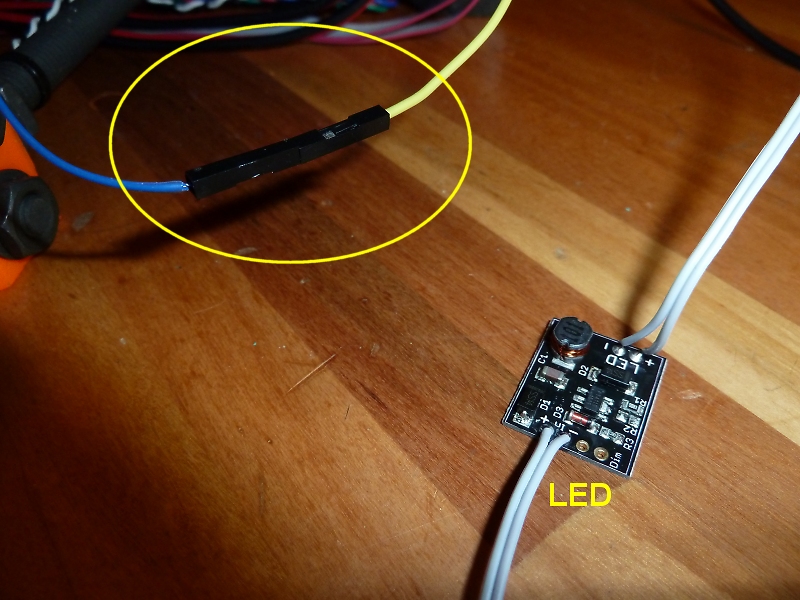

Picture shows an plug for the 3rd PWM wire of the fan. It's not necessary, but it's easier for future maintenance of the printer. Picture also shows the CCS (constant current source) for the LED in the bottom of the extruder.

Fan works superb. You can control the speed from about 10% to full 100%. If fan accidentally stops it will be automatically restarted after a few seconds (auto-start). You cannot set fan below 10% because it is running with minimum speed to keep it alive rotating. But this is no problem, at 10% fan is only blowing like a light touch.

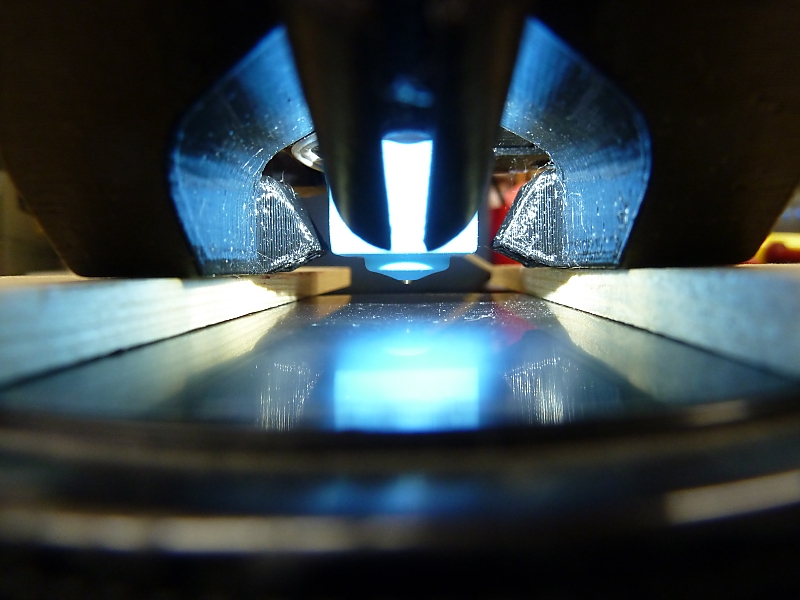

Illuminate ! 😎

Picture shows the nozzle with blue sock as seen from the endoscope camera.

In the next days I will update the whole printer with new bearings and rods from igus. I also will replace all printed parts and the PEI.

(see PRUSA blackPC edition at http://shop.prusa3d.com/forum/improvements-f14/prusa-blackpc-edition-t4723.html )

Thomas

Re: alternative nozzle cooling

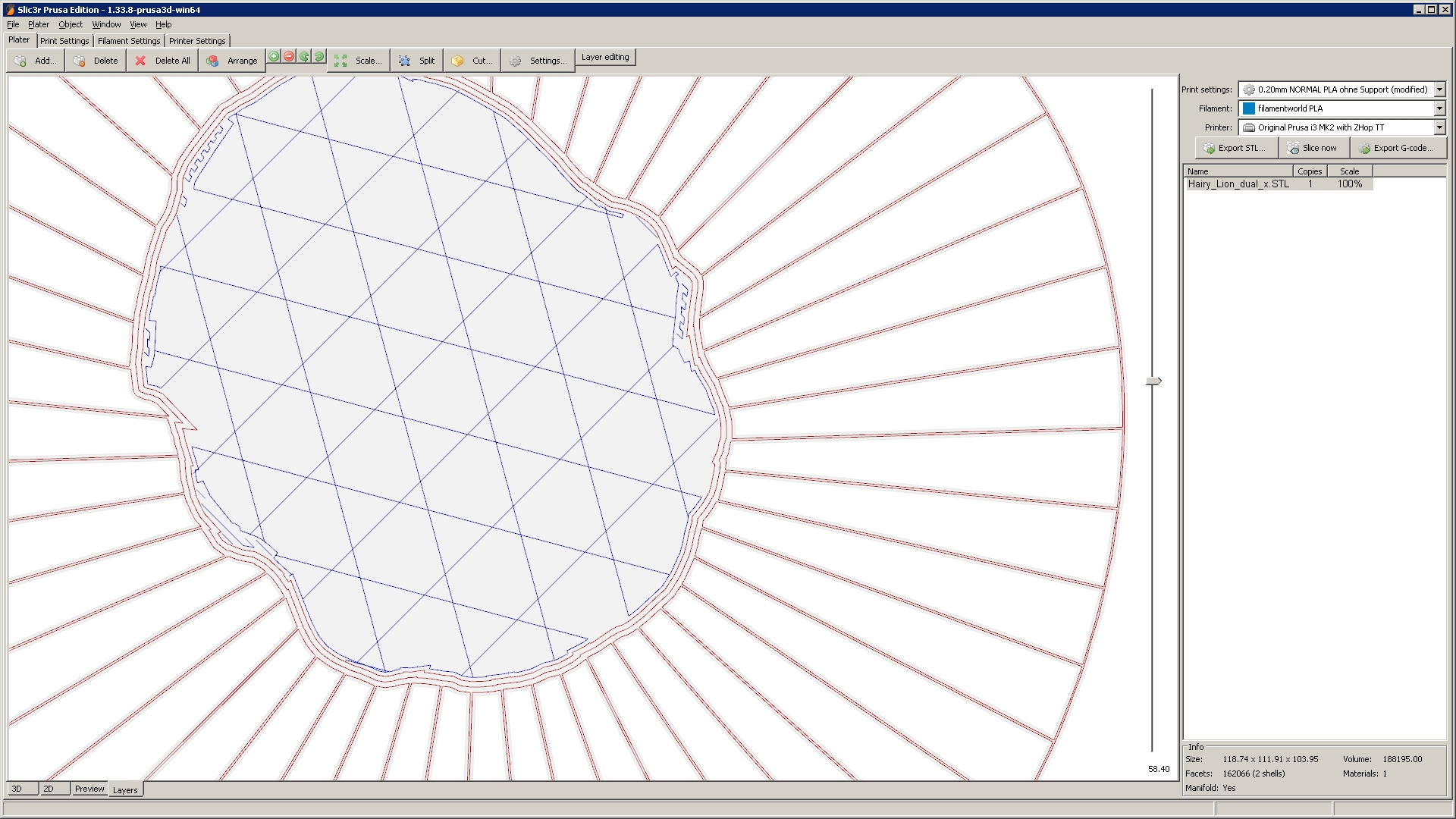

Design is working. Prints very nice with the new bearings an rods. But the cooling is very heavy and sometimes inhomogene. Maybe the holes in the fan duct are too small. Updated the duct to a more lighter design with more cooling outlet and nearly around the whole nozzle :

What do you think ?

Is it a problem to cool the Pinda active ? There is not enough space.

Thomas

Re: alternative nozzle cooling

After solving a problem with overextrusion, I replaced the stock extruder motor with an 0.9° stepper, I made some tests with the new configurstion.

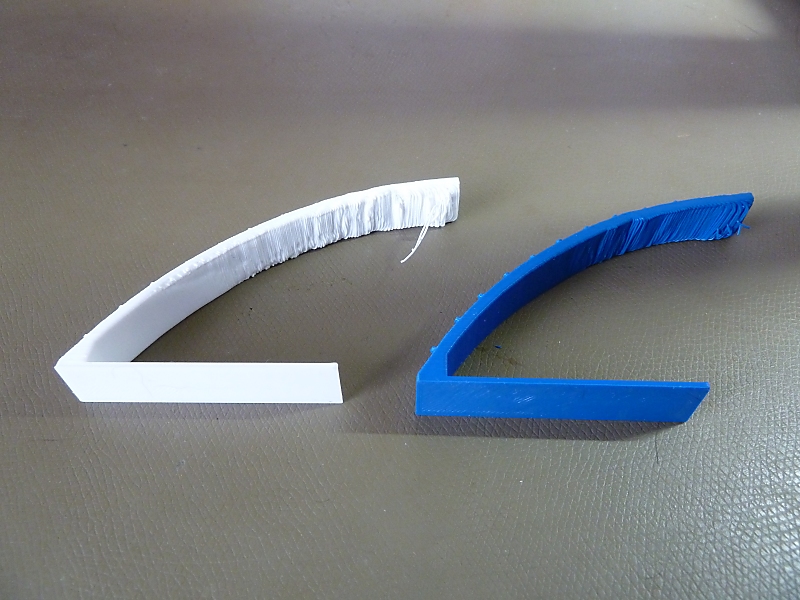

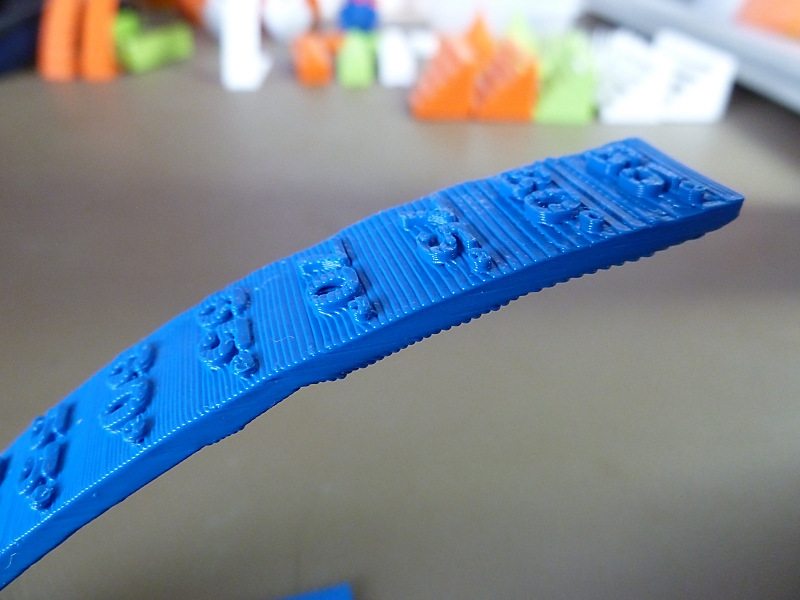

Back to the original design :

I printed some testing objects. Left side original PRUSA, right side my modded design.

The cooling test looks good :

Overhang test :

Increasing of about 10°, can now print 65° without support.

Re: alternative nozzle cooling

Updated the fan shroud to a complete new redesign. It's designed by myself, not "stolen" and adapted to our printer.

I added an LED light to the shroud.

Fan outlet goes nearly around the whole hotend.

Will print this new shroud and test it. Please hold the line ...

Thomas