RE: why did this make spaghetti -- needs supports?

Look closer, oh skeptical one. Nothing missing. You're just thinking the added break-away truss was the elimination of that little hookie-phone-grabbie thing. You added a "automatic" support, I added a smarter one than you did. Get over it jerk. I wouldn't have even bothered if I thought you'd just continue pressing your "only I can be correct" communication style. Is there a "block" feature on this forum?

RE: why did this make spaghetti -- needs supports?

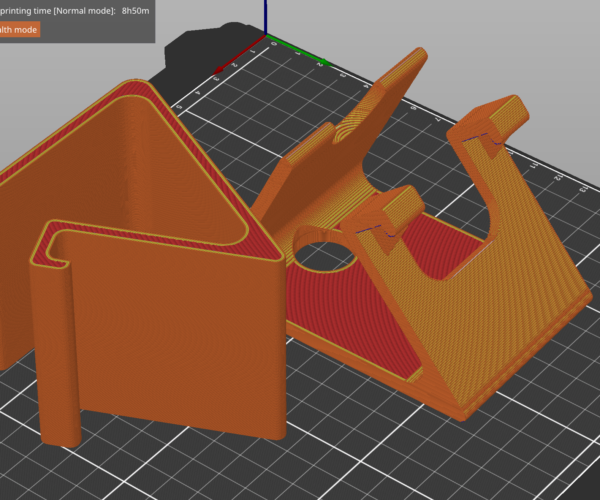

[...] I did make a slight change to the model - two break-away supports to eliminate the impossible angle at the very top of the model. by using simple break-away truss, there were no unmanageable bridges left, and at the end of the print, the break-away just broke away and no support mess to clean up.

Can you elaborate on what you did? Did you pull the STL into design/CAD software or add parts in PrusaSlicer?

RE: why did this make spaghetti -- needs supports?

An overly long conference call gave me a chance to play around a bit. I decided to stick with the honored James T. Kirk tradition of cheating when the problem is too complex, so went with:

- Adding breakaway sacrificial tabs using Add part in PrusaSlicer.

- Respinning the part to be easily 3D printed.

Now technically, either approach violates the rules of the scenario premise of "without support"...

- The tabs are support, plain and simple. Just arguably "part of the piece" at this point. I do still worry about the undersides with those fillets though. Any reorientation is likely to present bottom fillet challenges. The design is a stinker in that regard.

- The redesigned part doesn't use support, so I'm going to say it's a valid solution. I was able to stay pretty close to the original dimensions.

If nothing else, a fun exercise with a "how would you do it" scenario. Both prints are within 10g of filament and a few minutes of print time.

RE: why did this make spaghetti -- needs supports?

@bobstro

Hi bobstro ,

I don't have good luck with the PS rotate tool (it's settle tool is not very effective) so I opened the model in 3d builder to do the spinning and bed settling. 3d builder's "settle" feature is like gravity - it'll settle it. Then I noticed the little grabby things. So I added two .3mm parts that don't technically touch the model, but are within .1mm - they extend parallel to the phone holder grabby bottom, from the wall to the tip of the impossible part to print. With the non-model-modifying change in place (my break away supports), I imported into PS and sliced it. You can see the breakaway truss (it's what that other guy was whinging about) in the pics. Once it was printed, there was zero cleanup, the breakaway truss just pulled off. It was _just enough_ to keep the model from having a crazy support's need to be sanded off problem.

RE: why did this make spaghetti -- needs supports?

@bobstro

Here's the file with my breakaways. Doh. It won't allow that type of file. (stl) Too bad. In a forum called "how do I print this" - helping people understand that the check-boxes on the slicer aren't always their only best option is my motivation. It is NEVER out of bounds to try something that works, and any *ssh*le that thinks different, well, that's why *ssh*les are like opinions. Everyone's got one.

RE: why did this make spaghetti -- needs supports?

You need to zip up any attachments. It's annoying but saves some space.

RE: why did this make spaghetti -- needs supports?

I think you may have misunderstood @neophyl. I had the same question and was genuinely curious if you found an orientation that worked without mods. Nothing wrong with a fix, of course, but we do like challenges. @neophyl is a solid contributor here. Happy printing.

RE: why did this make spaghetti -- needs supports?

@terry-8:

As you see there are several ways to address this issue which was caused by poor initial design.

As I said:

A very simple design change, eliminating the cut-out, would have resulted in a much simpler print with no need for support.

and @bobstro has shown you how.

@neophyl pointed out there is no way to print the original file without support -

@dan-rogers then showed it is possible - but only if you add objects that do the job of supports but aren't actually called supports...

You added a "automatic" support, I added a smarter one than you did.

All of whch goes to show there is more than one way to do it - but it's much easier if you start with a well designed and tested object. Weeding out the dross is the hardest part for a beginner. We all learn in the end.

Cheerio,

RE: why did this make spaghetti -- needs supports?

Wow this thread blew up just a little bit. Just spent 3 hours fixing my sewing machine and its now 1:30am. Wish it was as reliable as my Mk3.

I'm sorry if I offended you Dan. Forums don't really excel in nuanced communication unfortunately, none of it was intended as you seem to have taken it. As Bob says its genuinely great to find a new technique and I really like finding new stuff. I agree with you on trying new things to push the boundaries of whats possible. I was just hoping that you had come up with something I hadn't seen before.

As for being a jerk, mmm possibly. That's a matter of opinion and you are certainly entitled to yours. I'm sure if you check out my post history though its much like your own, mostly posts trying to help people out. I don't have a sense of humor though, as a software tester we have that surgically removed upon qualification. I suppose that could be interpreted that way.

RE: why did this make spaghetti -- needs supports?

Wow! Blow up indeed.

--------------------

Chuck H

3D Printer Review Blog

RE: why did this make spaghetti -- needs supports?

As I said:

A very simple design change, eliminating the cut-out, would have resulted in a much simpler print with no need for support.

and @bobstro has shown you how.

The cut-out free version breaks the design though. I don't see the purpose of the half circle at the base, but the other two are for cable routing.

RE: why did this make spaghetti -- needs supports?

In that case:

- Use U-shaped cutouts open at the top.

- Use 3D print-friendly shaped openings, perhaps a hexagon with the flat at the top for easy bridging.

- Use rounded openings but leave a thin sacrificial layer for support.

The point being that a part designed to be 3D printed is much easier to work with. A lot of designs you find online are somebody's artistic take, and not necessarily going to print well without some effort.

RE: why did this make spaghetti -- needs supports?

If it prints better, I am all for the new design.

--------------------

Chuck H

3D Printer Review Blog

RE: why did this make spaghetti -- needs supports?

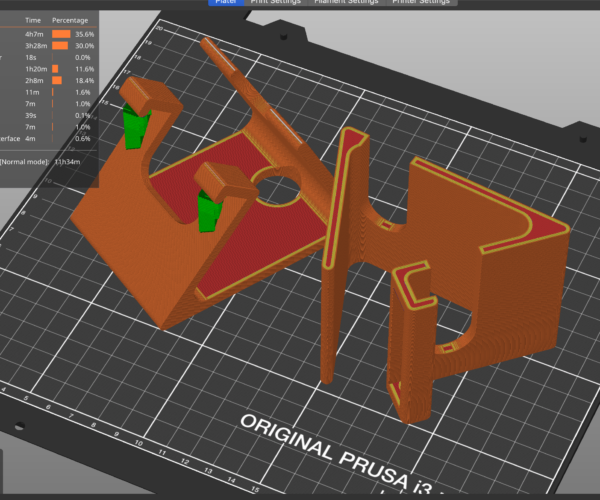

Just a little more fun with cheating on the challenge:

- Left: Original with selective paint-on supports.

- Right: Refactored design with easy print openings.

Obviously, you'd want to print these to verify the quality. I'm just not set up to do so today. The underside fillets on the original (left) are going to be ugly, so this is a suggestion only. The cutaway (right) version may need some tinkering with perimeters for strength.

Anyhow, just some ideas for solving the challenge.

RE: why did this make spaghetti -- needs supports?

...and now a new remix of this design appears, preserving all the design flaws of the original:

https://www.prusaprinters.org/prints/55749-tabloid-stand

Cheerio,