TPE print problems

Hi everyone, I'm having a little trouble as you can see from picture, I can't seem to get the strings to go away even with avoid crossing perimeters checked, I'm also running 0.2 retraction and an extrusion multiplier of 1.15, any ideas would be greatly appreciated, thanks in advance!

RE: TPE print problems

do you really need an extrusion multiplier of 1.15,?

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: TPE print problems

Um, not really sure, still kind of learning about all the various settings in slicer, I used the filamentum flexfill 92a preset (but I am actually using filamentium 90a TPE) in prusaslicer and it put 1.15 there, should I lower it a bit? I figured checking "don't cross perimeters" would stop it from hopping over like that and leaving the strings but I'm very open to learning the proper way to remove those unsightly strings from existence 🙂

RE: TPE print problems

My guess is you have problems with the model; and don't have filament drive tension dialed in (TPE takes a lot less tension that PLA or PETG), those and you are likely printing too fast. And keep in mind TPU will generally stick so well to smooth PEI that removal is a consideration, e.g., I would never use brims.

Since you haven't provided your project file; any thoughts as to why you are having issues would be guessing, so, I'll stop here.

RE: TPE print problems

Please post a Zipped up .3mf project file so we can take a look at your settings. it would also be helpful to know the brand and type of TPE your using if it's not mentioned in the .3mf

Good Luck

Swiss_Cheese

The Filament Whisperer

RE: TPE print problems

Sorry for the delay in reply, stepped away for a bit but thank you all for the replies, I linked the 3mf file below, pardon the file size, it's an undecimated mesh from zbrush so it's a little on the heavy side.

The filament I'm using is fillamentum flexfill tpe 90a, not sure how to adjust the filament drive tension unless you mean backing out the screw on the door, which is backed out to pretty much just barely holding on to the door nut but as far as print speed, I slowed everything down to 20ms.

The pei sheet I'm using is covered in clear packing tape which I started using after many, many tries at defeating poor tpu/tpe adhesion and lifting with the powder coated sheet with and without glue with little success, this packing tape setup with a brim and the build plate heat turned off actually seems to be working flawlessly every single print, just a pain to setup/remove after each print. (I am hoping to get my hands on some of the new satin sheets soon in hopes they hold well without all the hassle of the packing tape.)

Overall it's printing well as far as layers/adhesion and lifting are concerned compared to my previous attempts, if I could get that stringing under control it would be near perfect, is it that I need to bring retraction back up or reduce the extrusion multiplier perhapse?

Thanks again for all the help!

RE: TPE print problems

I spent some time with the model. To say it has a lot of errors is an understatement, and it is huge file wise.

That said, I beat it into submission for testing and came up with a few things:

1) Rotate it so up is up. It will reduce the support structure to something reasonable and make the final part usable. I painted on supports along the bottom. The upper spots that need support will probably print with minor defects. A test print then add supports if needed.

2) Do a good error check and repair on your model. NetFabb got a few of the errors, 3D-Builder got a few more. And I used Meshlab to reduce the model complexity to make the file workable. Then a couple of passes through NetFabb and 3d Builder again.

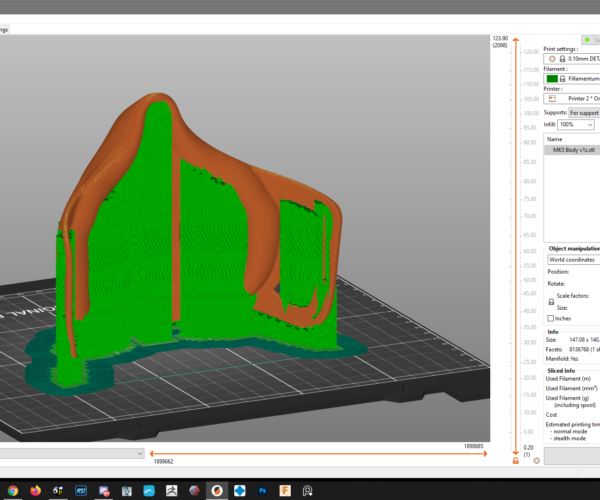

Here's an image of how I positioned it in Slicer.

RE: TPE print problems

My setup ... this is where I'd start. I'd use the Generic FLEX profile then tweak temps to the your TPE specs, or if someone's made a profile you know to work well with whatever you are using (i.e., prints smaller parts without issues).

RE: TPE print problems

And a last thought: the part you are trying to print is challenging with easy plastics. And hypothetically - TPE can droop and depending on just how bendy your TPE is, you might need to add some tree supports to hold the mask in position. You'll know if the mask starts to droop. The TPU I've used would probably print that mask as shown... but the stuff I use is somewhat stiff.

RE: TPE print problems

@tim-2

Hi Tim, thanks so much for looking at the project file, I have been making so many revisions to the model over the last few months I've gotten a little lazy, the mesh is fine when it comes out of fusion but I use zbrush to make some slight adjustments that I don't know fusion well enough yet to do and then get a little lazy and don't optimize the mesh since I can push it through and get a test print off, the final model will definitely not be such a mess, I swear 🙂

use zbrush to make some slight adjustments that I don't know fusion well enough yet to do and then get a little lazy and don't optimize the mesh since I can push it through and get a test print off, the final model will definitely not be such a mess, I swear 🙂

as for your image, if I were skilled enough in slicer to get what I see in that image, I would be a very happy person, my support results from using the default "autoset by angle" at that rotation angle give me what you see in the linked image and being that its supposed to sit comfortably on your face, the upside down direction at least gave me a clean nose/cheek area and I would sand the rest.

So I would love to know the secret, I come from a 3d background but my printing skills though I've learned much over the last few months, is still a bit lacking lol.

RE: TPE print problems

@tim-2

oh wow, thank you for this, I am loading it up right now!

RE: TPE print problems

@steve-t

Use PAINT ON SUPPORT. It is like painting in 3D ... easy peasy. Click the "brush" like control on left side of the plater page. Then point and click. You'll learn how it works in about 5 seconds.

If you load my model, select the platter page then the part, then the brush tool, you can flip the view around and see the spots I painted.

RE: TPE print problems

@tim-2

Wow, loaded and sliced and it looks awesome, almost 1/2s my print time minus all that support material!

yeah I'm definitely loving the paint on support system, I just guess I don't really know what I can/cant remove yet as I don't really have a good feel for what the mk3s can do when it comes to the extreme overhang/organic shapes I'm throwing at it lol. I figured all blue overhand areas needed to be supported, looking at that sliced model from below, those blue areas are ok to just let it print an overhang unsupported?

RE: TPE print problems

Low spots of course have to have support. But, with Detect Bridging Perimeters enabled, the spots that need support will turn dark bluish. Work back and forth between the paint tool and slice previews to place supports where needed. All you need to do is paint the blue spots with a dot. But beware a tall 2mm x 2mm support tower will fail 90% of the time.

Once you're done placing supports, good advice is to then turn off detection before the final slice and gcode generation.

Regarding if a spot really needs support. If you can tolerate a cosmetic "ugly" rash in an area, many overhangs -- e.g., when building a part with a large hole in it -- will print, just not be pretty. One continuous perimeter that overhangs might come loose, or it may droop a lot and disturb the surrounding area. Even air flow from the cooling fan can affect it. The spots in the holes on your mask and at the crown of the nose flap look small enough at 0.1mm layer height I'd try printing them before wasting filament for support. If printing at 0.2 mm, they probably need support.

RE: TPE print problems

@tim-2

Thats a chunk of knowledge to absorb, thank you, had no idea turning off detection would even have any effect on the slice and I'm gonna spend a bunch of time playing around with support settings, I'm sure at the rate I've been going, it will save me a lot of filament!

Gonna print this at 0.1 in hopes to get good layer adhesion so ill just load up as is and give it a shot, see what comes out and adjust from there, a little ugly on the underside of the holes wouldn't be too bad as I've had lots of practice at clean up so far so at least I'm kind of good at that I think lol.

Thank you so much for all the information and help Tim, I appreciate it greatly, I will print this one out as you sliced it and report back with the results.

Have a great evening!

RE: TPE print problems

@steve-t

The world is dying to know, how did it work out?

The Filament Whisperer