Struggling to get a clean print with 3dxtech CF Nylon

Hi folks

Just started with printing with 3DXtech CF nylon and just cant seem to get a clean print out of it.

Filament is definitely dry, being put in humidifier at 70C for 13 hours. Nozzle @ 265c and bed @ 85. No problems getting it to stick with magigoo PA glue

Have tried;

- No Z Hop

- Lower Retraction speed (but retract dist kept at 0.8mm)

- 0.95 Extrusion Multiplier

- Lower nozzle temp @ 255c

- Slowed speed 70mm/s down to 50mm/s

Nothing seems to work, I’m getting a consistently bad result, and they all seem to be bad in the same places.

Not a lot of info on this filament for the MK3S that I can find, but if anyone does, I’m all ears

Thanks

Sam

RE: Struggling to get a clean print with 3dxtech CF Nylon

Does the filament extrude clean, when extruding in the air?

I looks like a humidity error, but you have dried it before use. Next thing that comes to my mind is debris in the nozzle, maybe it needs a cold pull.

Have a look at my models on Printables.com 😉

RE: Struggling to get a clean print with 3dxtech CF Nylon

Generally speaking, CF Nylon is considered to be an abrasive material, and a harden nozzle or something more durable than brass is recommended, but I dint see what sort of nozzle you said you had.

Also going from the manufactures recommendation here

https://www.3dxtech.com/carbon-fiber-filaments/carbonx-nylon-pa6-cf/

It mentions to keep no lower than a 0.25 for the layer height, what are your layer height set to?

I did not see any mention about cooling, but what is your fan set to?

And if you look at their recommended drying times, you are leaving the filament in for 3 times longer than recommended.

https://www.3dxtech.com/drying-instructions/

Also did you try to reach out to them and see what they say since it is their material and they would be a good source as far as correct settings and see if you have to adjust cooling, and / or retraction distance. as well.

Shane (AKA FromPrusa)

RE: Struggling to get a clean print with 3dxtech CF Nylon

Thanks for your response

Have tried various settings now and still can’t stop the stringing

Nozzle is 0.6mm E3D Nozzle X

Have tried layer heights at 0.30, 0.35 and .40

Cooling settings either on or off do not make any real difference, likewise speeds (from 60mm/s down to 30mm/s), and nozzle temps 265-255.

I’m getting too lost now in the variable amount of settings that its hard to discern what particular thing/things is causing it.

I did some slightly better results with a lower extrusion multiplier

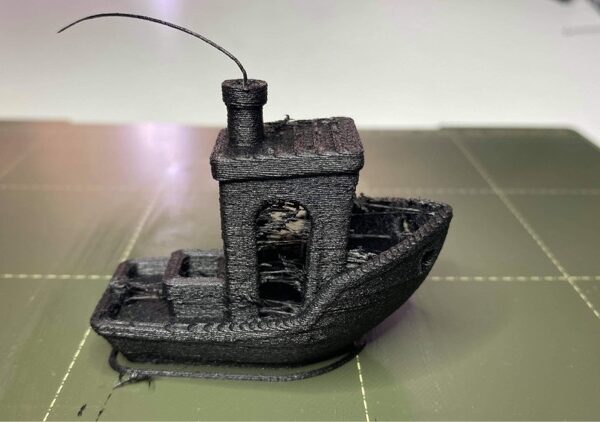

This is the bottom part of the PSU holder for the ikea lack enclosure

This was printed with quite aggressive settings, a 0.80 extrusion multiplier and a 2mm retraction distance, which is the max I want to go before possible jamming/clogs. Apart from the burrs the print is not too bad, maybe this filament is more limited to larger prismatic type parts without complex geometries. Also note the layer shift towards the top. I also got a bit of this with my regular setup in PLA so not sure if this is just a model problem (any ideas?).

I wouldnt be too particularly worried about the above part and doing a bit of post processing, but I do wonder about the layer adhesion and if the part is really any stronger than 910 or any other good nylon, even if the rigidity of CF isnt there. Hoping to get access to my universities materials testing lab in the next few months which will give a clearer picture.

RE: Struggling to get a clean print with 3dxtech CF Nylon

I am having the exact same issues as you with the exact same filament. I seem to be getting some slightly better results with the part cooling fan on, but that will probably affect part strength, which is the most important thing when printing this type of filament.

RE: Struggling to get a clean print with 3dxtech CF Nylon

Anybody made progress on this filament?

RE: Struggling to get a clean print with 3dxtech CF Nylon

@hiro-protagonist

Yup, it was a moisture issue. Had to dry the spool for 18 hours @ 75C. Yup, 18 hours. Tried it for 6 hours first, still wet. 12 hours, still oozing slightly... 18 hours was just the ticket and it stopped oozing. Made the printing quite a lot better, but i still had big issues with the .6 nozzle. Swapped to a .4 nozzle and now i'm getting prints that im happy with.

RE: Struggling to get a clean print with 3dxtech CF Nylon

you should also continue to dry it as your printing with, if you have that capability.

Good Luck

Swiss_Cheese

The Filament Whisperer

RE: Struggling to get a clean print with 3dxtech CF Nylon

Thanks for the followup info. I do have a SunLu drier, so can dry and keep dry.