Strange bridging like stringing

Hello there,

I'm a maker since 2017 and just changed my Anycubic to an Original Prusa i3 MK3S a few weeks ago.

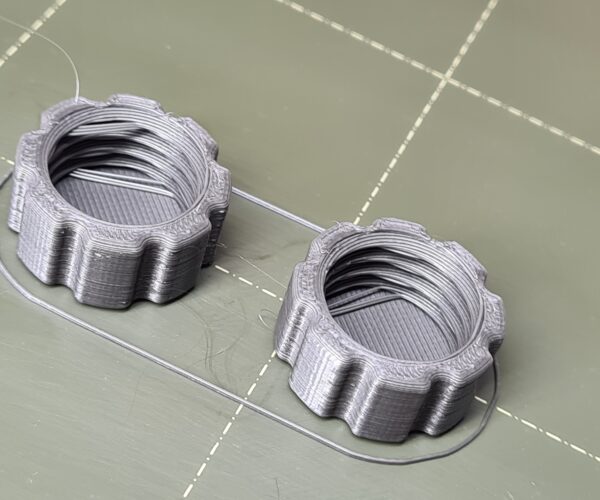

I tried to print some screw caps that I designed with the standard settings in Prusa Slicer: 0.20 mm QUALITY. I use the standard filament settings for Das Filament PLA (I took this settings straight from Prusa Slicer and had no issues with it until this print. The temp tower came out fine as well and confirmed the "factory settings" for this filament).

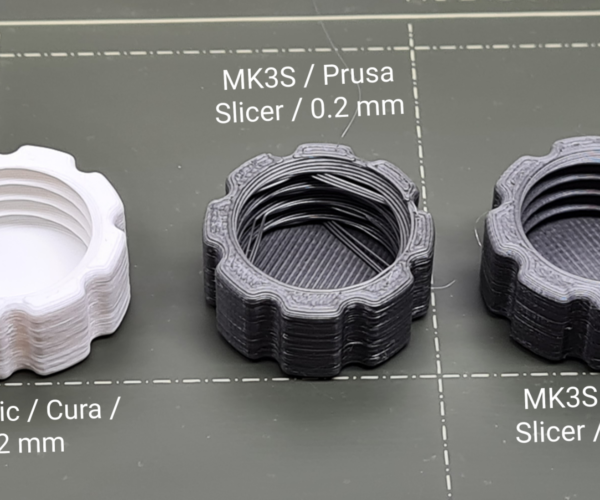

I printed them before on my Anycubic with Cura at 0.2 mm without any issues (except the lower quality outer shell).

I guess this might be some kind of "do not retract if travel is shorter than ..." problem but I don't find the setting. On the other hand this does not look like stringing at all but like bridging.

But why? How do I avoid this issue?

Here's the STL-File: https://cdn.thingiverse.com/assets/7d/4f/ff/67/80/Deckel.stl

Best Answer by bobstro:

It is adhesion. Those internal threads are extreme overhangs. Things to try:

- Slowing speeds to give the filament time to fully adhere to underlying layers.

- Increasing temp or reducing cooling slightly.

- A lower layer height.

RE: Strange bridging like stringing

It is adhesion. Those internal threads are extreme overhangs. Things to try:

- Slowing speeds to give the filament time to fully adhere to underlying layers.

- Increasing temp or reducing cooling slightly.

- A lower layer height.

RE: Strange bridging like stringing

What size nozzle are you using? It's probably just the pictures but those layers look bigger then 0.2

The Filament Whisperer

RE: Strange bridging like stringing

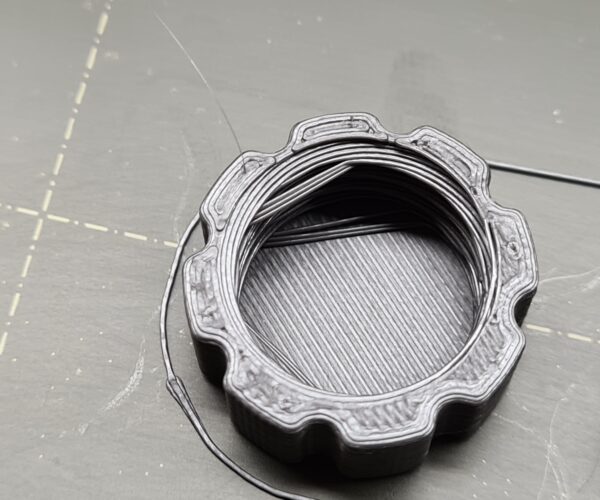

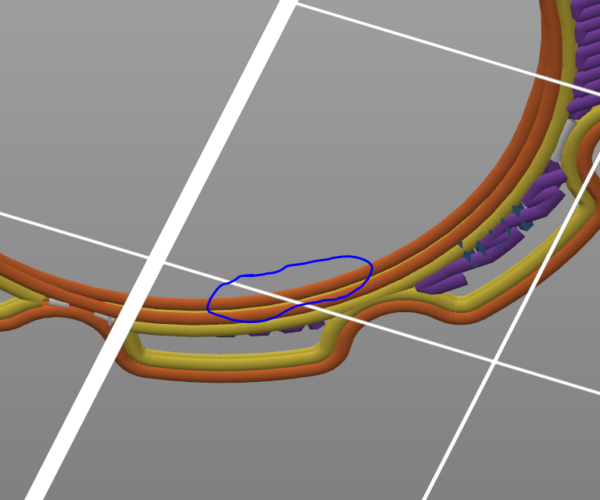

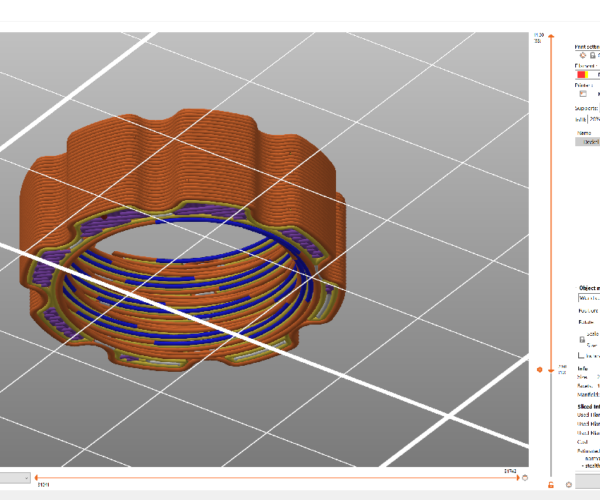

Ditto on what Bob said. There are bridging perimeters on the part - check the "Detect bridging perimeters" box in slicer and look for the dark bluish lines. Wherever those exist, the nozzle is printing in free air and pulling the filament along like a rubber band until they stick to something. Reducing layer height is about all you can do, especially with threads.

RE: Strange bridging like stringing

Ditto on what Bob said. There are bridging perimeters on the part - check the "Detect bridging perimeters" box in slicer and look for the dark bluish lines. Wherever those exist, the nozzle is printing in free air and pulling the filament along like a rubber band until they stick to something. Reducing layer height is about all you can do, especially with threads.

There are no bridging perimeters.

What size nozzle are you using? It's probably just the pictures but those layers look bigger then 0.2

The standard 0.4 one that came with the kit.

Thank you @bobstro I reprinted the parts with a 0.1 layer height and they printed perfectly.

Never the less Prusa Slicer didn't identify any problems and these overhangs and I didn't expect them due to my experience with my old printer in combination with Cura slicer. Perhaps the part cooling is just much better.

RE: Strange bridging like stringing

Never the less Prusa Slicer didn't identify any problems and these overhangs and I didn't expect them due to my experience with my old printer in combination with Cura slicer. Perhaps the part cooling is just much better.

I spent a lot of time with this same issue during the PPE printing push. Some of the shield frames were very susceptible to this exact issue. I found it was always a bit of a balancing act between prints, particularly getting nozzle temps and cooling to cooperate. I believe there's a plan to allow for separate cooling for external perimeters versus internal which would help quite a bit with these sorts of prints.

On more complex prints, don't forget you can use modifiers to adjust settings throughout a print. I would up using 30% cooling on some overhangs to help reduce sagging.

Glad you got it working well. It's a never-ending learning process.

RE: Strange bridging like stringing

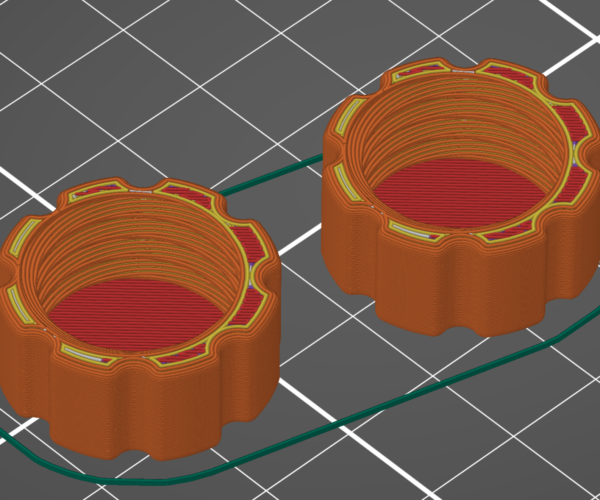

Here's a snip of two layers at 0.20 - the inner extrusion is not supported by much, if anything. Yes, there is sufficient contact it isn't flagged as bridging, but for all intents and purposes, it is a bridge. This is why the part was failing. At 0.15 or 0.10 the contact area is more substantial.

I long time ago I did a drawing that explained why in detail - but it was lost in the forum update. I should probably go back and redraw it.

RE: Strange bridging like stringing

@tim-m30

thank you for taking time and finding the reason of the issue in my model. Are unsupported overhangs not colored in red by default?

RE: Strange bridging like stringing

@t-j

When they are 100% unsupported, they get colored as you'd expect. Here' your part at 0.3 layers, and the unsupported bridges show clearly.

The clue this is happening in real life is the rubber-banding of single extrusion. It's either printing too fast (plastic not adhering to lower layers) or printing mid-air (nothing below to adhere to). Plastic is normally squished wider than 0.4 mm - and the slicer expects all layers to be squished. When something isn't being squished, the two adjacent perimeters don't touch, the extrusion is only 0.4 wide and misses the fractional ledge it is supposed to meet with, and you get a rubber band.