Someone with an i3 and a .25mm nozzle who can do a test print?

Hey guys!

I'm sorry if this is not the correct part of the forum for such a request ;-D I realize that this is a long shot, but I'm looking to replace my current printer* with a Prusa printer (haven't really decided on the mini or the i3 yet). No matter the layer height, speeds, retraction (settings in general), slicer or physical conditions I still get the same results.

I realize that this is a challenging little part, but I highly doubt that I'll ever get good results with this printer. I have only had a total of ~4 successful prints in 100-200 attempts in the entire lifetime of the printer. Trust me, I have tinkered. A lot. Applied all the mods supposed to "fix" this printer. It's just a broken design (which is slaughtered on the interwebz).

Back to the point. Before I purchase the i3 mk3s, I want to make sure that it's actually realistic to print this part with a FDM printer in the "home/hobbyist" class. If one of you makers out there have an i3 which happens to have a precision nozzle mounted (this is probably too small a part for a .4mm nozzle) and a bit of spare time, can someone try to print this little fellow?

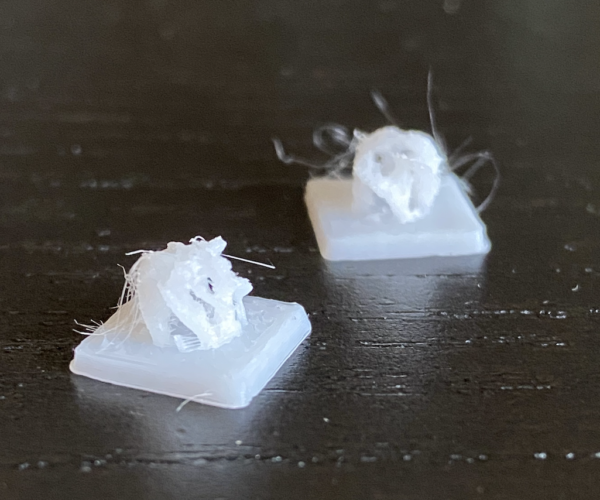

Attached my best (!) result and STL.

*Solidoodle Press. Early adopter. Not proud.

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

Here you go,

.4 nozzle, .1 layer height, in PLA. 100% infill.

6 minute print on a Prusa i3 Mk3/s

I don't have any smaller nozzles! 😉

I went through so many Chinese printers before I finally went for the Prusa. I have never looked back! Regardless of so-called tweaks and mods recommended on YouTube et al, every clone printer I had was awful.

Enjoy.

T

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

@timshelbourne

What a timing, just as I had just printed my 20th attempt. It's so obvious that my printer is.... inadequate. Solidoodle was actually a somewhat successful american company for some years, and to my understanding their printeres were original - but ironically after the release of my printer they shut down 😉

Thank you so much for doing the test print.. The result really speaks for itself.

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

@timshelbourne

Out of curiosity, did you slice it with all default settings or did you fiddle with some minimum layer time settings for instance?

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

For grins, I printed it at 0.4 mm nozzle, 0.1 layers.

ps: pretty much default settings on a 3 year old Mk3.

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

@tim-m30

Thanks for taking your time to print it too! I’m really surprised how accurate the dimensions seem to be and how smooth the surface looks. Seems like I’m getting a Prusa 😉

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

These sorts of prints are a no-brainer for the Mk3. I happened to have a 0.30mm nozzle mounted with PLA. You can use variable layer heights to get very close tolerances.

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

@bobstro

Actually never tried the variable layer height, but it sure seems like a genius concept for high precision areas of parts. PrusaSlicer supports that, right?

At what speed did you print your examples?

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

[...] Actually never tried the variable layer height, but it sure seems like a genius concept for high precision areas of parts. PrusaSlicer supports that, right?

It's definitely worth playing around with it. It can dramatically speed up prints while still keeping thin layers where appropriate. In PrusaSlicer, select your part, then click the third button from the right at the top. The controls are a little funky but easy to figure out. Every part can have different layer heights, so you don't have to create a separate job for various parts.

At what speed did you print your examples?

I normally use 25mm/s for external perimeters and 60mm/s for other perimeters. On parts this small, you never get near those max speeds though. The only part printing much faster than 25mm/s is the infill on the bottom part.

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

Thanks for all your replies. I just bought the i3 kit, can't wait for it to arrive!

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

@felix-w

When you receive the kit, remember that building it is not a race. Take your time, read the manual and follow the build guide on the web religiously and you'll save yourself some serious headaches.

One deviation I heartily recommend: clean and pack the bearings with grease BEFORE you install them. Rinse them well with alcohol to remove any machining debris, dry them with compressed air, and then pack them with Lubriplate or similar White Lithium grease.

A second deviation will be to not try to get the belt tension numbers that Prusa recommends. People have broken the tensioners trying. Get the belts snug, and if you see belt related printing issues, learn how to tension them properly.

And one last important thing: the smooth print sheet surface must be kept clean. No fingerprints. Handle by the edges, use tools to remove parts.

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

@felix-w

When you receive the kit, remember that building it is not a race. Take your time, read the manual and follow the build guide on the web religiously and you'll save yourself some serious headaches.

Great advice, I’ll bear that in mind. I’ll clear my schedule the entire weekend after it arrives, I imagine the assembly is critical for the success, so spending a little extra time is probably well invested.

One deviation I heartily recommend: clean and pack the bearings with grease BEFORE you install them. Rinse them well with alcohol to remove any machining debris, dry them with compressed air, and then pack them with Lubriplate or similar White Lithium grease.

I don’t have a compressor at hand unfortunately, I’ll buy a can of compressed air. Will that do the job? Is grease included or should I get some?

A second deviation will be to not try to get the belt tension numbers that Prusa recommends. People have broken the tensioners trying. Get the belts snug, and if you see belt related printing issues, learn how to tension them properly.

I have no idea how to measure belt tension, but I guess I’ll find out when I receive the kit and read the manual 😁

And one last important thing: the smooth print sheet surface must be kept clean. No fingerprints. Handle by the edges, use tools to remove parts.

I’ll remember that! Browsing threads on this forum it looks like that’s the main cause of adhesion issues (along with miscalibrated Z).

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

@felix-w

Canned air is great to dry them.

Since you don't have a printer to print the grease tube caps, use a plastic straw or pen to squeeze grease into the rollers. The bearings don't need to be packed 100% full of grease, but all the rows should be wetted with it. Squeeze some grease into the bearing, insert a pencil, roll the bearing around the pencil a few times. Wipe off any excess on the outside. Common sense stuff.

Handling the bearings is pretty easy, too. Not sure how, but some people must insert the rods with a jack hammer and knock out the balls from the retainers: ease the bearings onto the rods, there should be no forcing involved.

Building the printer is fun, especially the Hariboo's ... and helps you down the road know how things are working.

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

@felix-w

Canned air is great to dry them.

Since you don't have a printer to print the grease tube caps, use a plastic straw or pen to squeeze grease into the rollers. The bearings don't need to be packed 100% full of grease, but all the rows should be wetted with it. Squeeze some grease into the bearing, insert a pencil, roll the bearing around the pencil a few times. Wipe off any excess on the outside. Common sense stuff.

I just checked the manual to see if grease is included; it specifically says "The printer's package contains a lubricant, which is intended for maintenance. No need to use it now the bearings are lubricated.". Even with this disclaimer, would you still lube the bearings? Or as you say, common sense - if it looks properly greased up, there's no need to re-grease?

Handling the bearings is pretty easy, too. Not sure how, but some people must insert the rods with a jack hammer and knock out the balls from the retainers: ease the bearings onto the rods, there should be no forcing involved.

Building the printer is fun, especially the Hariboo's ... and helps you down the road know how things are working.

Can't wait, I love building stuff!

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

Prusa insists the bearings are oiled. It is at best a distortion of the truth. But, you can install them as-is. You can buy Chinese knockoffs for $12 a set so they are cheap to replace when they go bad. Usually they fail within 6 months, so you get some use from them if you don't lube them properly. Rods are a different story: if they are scored when the bearings begin seizing, the repair gets more expensive.

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

It took me a week to assemble the MK3S (working just few hours a day).

The only challenge that I had was in building the Y axis assembly. Prusa recommends to tighten the M5 bolts with a torque of 4.5 Nm, which to me seemed quite high. The screws provided are made out of soft steel meaning that you will destroy the Allen socket in the head of the bolt if you torque it to the recommended specs.

It was a nightmare to extract the broken M5 bolts.

Eventually I replaced the provided bols with higher quality ones and with a hex head.

My recommendation: if you use the provided screws, tighten them progressively and stop immediately if you feel that the socket is failing.

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

It took me a week to assemble the MK3S (working just few hours a day).

I guess it will be realistic enough to assemble it in a weekend if I slot the time for it and ration the gummy bears to keep my sanity then?

The only challenge that I had was in building the Y axis assembly. Prusa recommends to tighten the M5 bolts with a torque of 4.5 Nm, which to me seemed quite high. The screws provided are made out of soft steel meaning that you will destroy the Allen socket in the head of the bolt if you torque it to the recommended specs.

I don't even own a torque wrench, so thats quite easy. Since it's the MK3S I assume you assembled it quite recently? I briefly ran over the manual yesterday, but I didn't notice any numbers. Tim also mentioned "belt tension numbers", which I didn't see either. I just saw some manual "try to move the belt, if it skips, it's too loose" and "tighten the bolt until it touches the plate, then turn another 90 degrees". So I'm curious if I'm missing something in the manual?

RE: Someone with an i3 and a .25mm nozzle who can do a test print?

Hi @felix-w,

I bought my MK3S about 18 month ago. After assembling the printer yourself you will know it inside out. Do not try to rush things and follow preferably the online manual. The printed manual tends to get updated less frequently.

The torque level of 4.5 Nm was mentioned in the old printed manual (not sure if it's a mistake because it disappeared from the online documentation). You can find the same comment in many forums. For example:

The Belt Tension number is calculated with a procedure that measures the current absorbed by the step motors. It's accessible from the menus. The procedure is at:

https://help.prusa3d.com/en/article/adjusting-belt-tension-mk3-s_112380

You can assemble it following the manual directions and then check the tension later from the printer menus.