Prusament PETG layer separation and corner lift

Hi all

This print went several kinds of wrong.

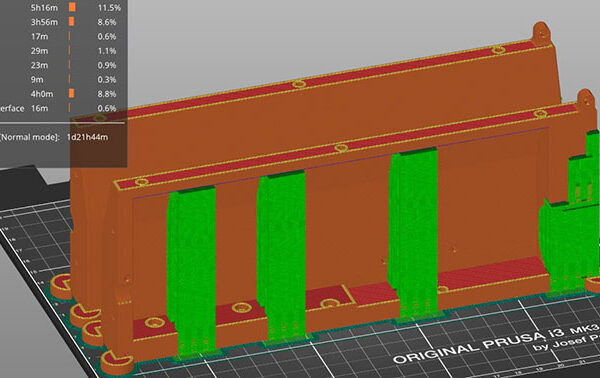

The pieces were designed on Fusion 36o, printed with Prusament PETG, sliced in Prusaslicer 2.3.0 using a slightly modified standard PETG profile (extra perimeters, brim, added 5ºC to temperatures). I am printing in a MK3 in an enclosure, using the latest firmware).

It was a very long print (roughly 46 hours), and the printer was left working overnight, with the enclosure door open.

This was the first print after installing a new nozzle and a new heat cartridge (it had to be replaced because one of the cables broke)

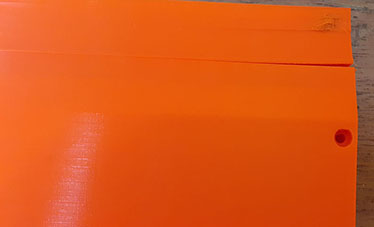

Here's what happened: I had a layer separation happen on both parts at exactly the same height, more noticeable on the right side of the bed.

Another issue is that the corners of the pieces have lifted from the bed, even with a 3mm brim and "corner heat protection" thingies (I designed pacman-like pieces that I place on the corners, these were 5mm high)

first image is a screenshot of the slicer to show you how the parts were placed

the second image shows both pieces, side by side

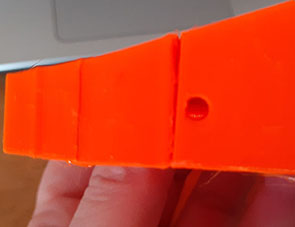

a close-up on one of the pieces

the two pieces side by side. It appears to also have a layer shift? I don't know if it happened or if it is a consequence of the layer separation

a close-up on the side of the piece

I have also attached a zip file with the 3mf file if someone wants to take a look.

Ok, so now the questions:

1- what may have caused this?

option a) temperature drop overnight

option b) nozzle clog that magically sorted itself out?

option c) something else I am not considering

2-what can I do to fix this?

option a) close the door of the enclosure overnight

option b) add a draft barrier or something similar

option c) change the settings on the slicer

I have read multiple posts recommending the increase of the flow rate, but I also read that this only fixes the "symptoms", not the "cause". I need to understand the cause and how to solve the issue.

I have also read that increasing the temperature also helps, but I already raised the temperature by 5ºC, is this not enough?

On another note, even with the "pacman" thingies in the corners of the pieces, I still had significant raising, enough that the pieces won't lay flat on a table. I need them to be perfectly flat. Is raising the height of the "pacman" enough to protect the corners? they can't be much larger, because I am already filling the full width of the print area.

Thank you very much for your time

Cheers

RE: Prusament PETG layer separation and corner lift

Whew. That's a lot of things. And that's going to be a bear to print as currently designed. At least in that orientation. Sure looks like it would be an easier print "hole side down" - but not having the 3mf, hard to say (you can zip it up and upload it on the thread)

RE: Prusament PETG layer separation and corner lift

@dan-rogers

thanks. Attaching the 3mf file now

I thought it was linked under the photos

RE: Prusament PETG layer separation and corner lift

@amarques

How did you create this part. It seems to be very odd (to me anyway)?

Are the circular features on the corners an attempt to reduce warping? If so as there are not attached to the main body they aren't helping that much.

RE: Prusament PETG layer separation and corner lift

@towlerg

The circular parts are there to prevent warping, yes. Do they need to be closer to the body? In fact, i did get warping even with the circles. I thought about making them higher. I can't make them wider because it won't fit on the printing bed.

The pieces are part of a bigger build. I will eventually print them again, hollow side down

RE: Prusament PETG layer separation and corner lift

@amarques

Hi

please see the attached file,

you will need to add your modifiers again.

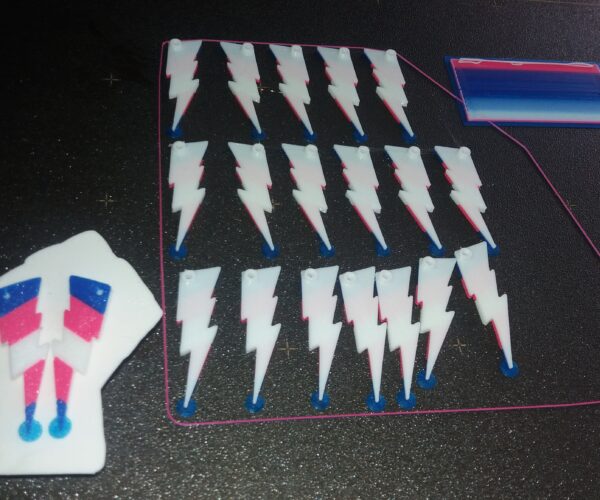

I have added Mouse ears and then saved the plate as an STL, to integrate the mouse ears into your model

I keep a standard 20mm diameter and 0.2mm thick

which I can either use as is, or scale as required.

you will see that I have re scaled the mouse ear into an oval. (don't forget to unlock scaling)

your corner re enforcements are probably a bit too tall,

I used tiny Mouse Ears to hold these points down

hope this helps, Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK