Problems wit adhesion of PETG

Hi everyone, I have a problem with the adhesion of the Redline PETG Transparent. I have a test sample of it because I want to print something from transparent material.

From the printing plates I have the smooth steel plate and the texted one (for which Prusa has a recommendation for PETG and ASA). I cannot get any liability together.

According to the manufacturer the temperatures are 220+-10 degrees, bed 60-80 degrees.

I have now at the 2nd attempt leaned on the temperatures the Prusa for their PETG filament and tried first and further layers with 230/80 degrees.

It looked like it would not stick at the beginning, but at 25 mm height the pressure was loose and I had to stop.

Has anyone had or solved similar problems?

Best regards

Charly

Translated with www.DeepL.com/Translator (free version)

RE: Problems wit adhesion of PETG

Usually PETG has opposite problem with smooth sheet.

There are two factors for the first layer: clean sheet and correct first layer calibration. Here you can find many suggestions how to do it.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Problems wit adhesion of PETG

As Zoltan said Clean sheet and Z are the main factors for most people.

I print a LOT of PETg, Some TPU, and Some ASA, and a little bit of PLA..

I'll add a few things.

1. First the sheets textured and smooth take a little bit to "Break In". They tend to be a little bit slippery when new. Some people use a very fine abrasive (like 2000 grit wet dry) to scuff the smooth sheet a tiny tiny bit. So even if you do nothing it'll get easier to print PETg as the sheet breaks in.

2. Hairspray. Works in 2 ways. It is sticky and helps the PETg, ASA, and TPU stay in place rather than being dragged. You get sharper corners, and levelling is much more forgiving. I have used hairspray on my textured and smooth sheets for a long long time. Works really really well. Make sure to use Aqua Net “Extra Super Hold” Unscented Hairspray or a known good equivalent. It also works as a release agent. It makes the print detach much more easily from the sheet when the sheet cools.

<I posted this earlier in the ASA announcement> For those of you about to say something negative about hairspray:

I print 90+% PETg, mostly on the textured sheet (sometimes the smooth). since 4/2018 I Have printed 48+ KG (tally of Amazon Rolls) of PETg, 4.8KG of TPU, 8 KG of abrasives + exotics like ASA, and 8KG of various PLA. Mostly on the Textured Sheet, some on the Smooth Sheet. Aside from the purge strip starting to show some wear (smooth has the nozzle heat bubble), and a noob mistake setting z too low, both sheets look perfect.

3. 220 degrees is low for PETg. I find most PETg prints well at 240-245 depending mostly on the colour. I suspect that at 220 you are going to under-extrude. Try a minimum of 240, you'll get more extrusion, and possibly more stringing, but the layers will stick to the bed and to each-other much better than at 220.

RE: Problems wit adhesion of PETG

I've had good luck with transparent PETg on both smooth and textured sheets.

At first I was using glue stick, mainly as a release agent, since it's been my experience that, if anything, PETg sticks too well.

Lately I've been using the Layerneer Bed Weld, both to help adhesion and as a release agent.

RE: Problems wit adhesion of PETG

I'm having the same issues with some PanTech 3D PLA that I have bought recently. They recommend 220-240 with a bed temp of 60-80. With those settings I have terrible intra-layer adhesion.

I'm giving it a go right now with 245 and 90 bed temp. Hopefully it will be better.

The page also recommends a print speed of 20-90mm a sec, but I have not found where to check that in prusa slic3r yet.

Te last thing I can think of to try it is to take the fan speeds down from 30-50% to 0 - 30% and see if it makes any difference at all.

RE: Problems wit adhesion of PETG

I'm having the same issues with some PanTech 3D PLA that I have bought recently. They recommend 220-240 with a bed temp of 60-80. With those settings I have terrible intra-layer adhesion.

I'm giving it a go right now with 245 and 90 bed temp. Hopefully it will be better.

The page also recommends a print speed of 20-90mm a sec, but I have not found where to check that in prusa slic3r yet.

Te last thing I can think of to try it is to take the fan speeds down from 30-50% to 0 - 30% and see if it makes any difference at all.

Can you please describe more your issue? PETG behaves quite differently than PLA ,so the issue could be also different. I would suggest to follow this guideline https://forum.prusa3d.com/forum/english-forum-general-discussion-announcements-and-releases/we-want-to-help-you-you-have-to-tell-us/

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Problems wit adhesion of PETG

Hi @ssmith

I do not think to increase the temperature over 225°C and decrease the the fan speed- cooling the printed filament especially PLA is very important. WOuld be great, if you could attach any picture.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Problems wit adhesion of PETG

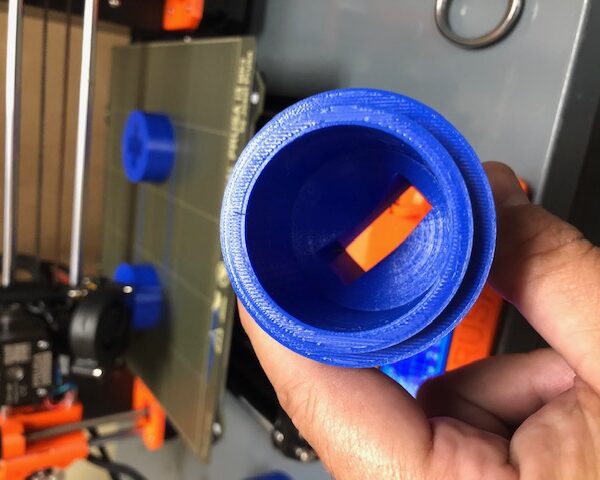

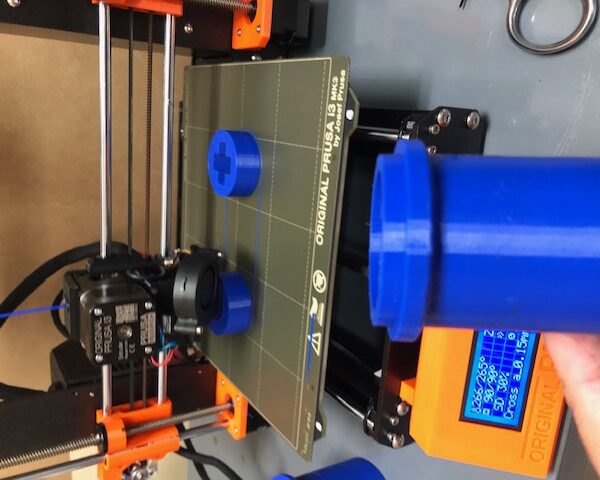

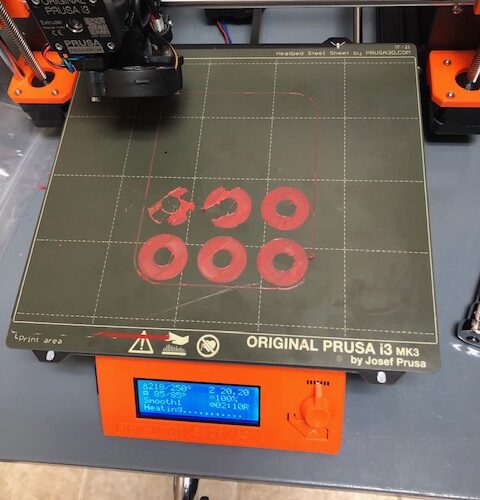

I started printing with PETG with great success. Blue pieces using a 0.4mm nozzle 240-250 hotend with 85-90 bed. I then switched to a 0.8mm SS nozzle to print the red and white pieces. I wasn't happy with the resolution on these pieces but loved the speed. I then switched to 0.4mm SS nozzel and now I can't print a thing. It just globs up on the nozzle. I have cleaned the bed with 99.9% isopropyl alcohol, re-calibrated via wizard and tried to set the Z level for 1st layer and zero luck. Very frustrating. I have only been 3D printing for a few weeks but feel like I am going backwards. Any advice would be appreciated.

RE: Problems wit adhesion of PETG

Rekalibrate your first layer - seems nozzle is to high, PETG on the smooth should stick like hell unless your first layer is too high. Did you change your profile in Prusaslicer to 0,8 mm nozzle? Extruding almost twice as much material, probably the temperature is not enough to melt the whole material, increase by 5°-10°C.

Clean the sheet by dishwasher soup.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Problems wit adhesion of PETG

Changing your nozzle diameter you have to always reslice the .stl file with appropriate profile to get the correct G-code file !!!

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Problems wit adhesion of PETG

@zoltan

Thank you. I did change the nozzle in slicer and resliced. I will try recalibrating

RE: Problems wit adhesion of PETG

A few other things:

Changing nozzles will change your Z height. If you put the old 0.4 nozzle back in, recalibrate your Z. Make sure everything is appropriately snug.

Nozzle clog. Either (Heat and Clean/ Cold Pull) or replace it with a new one. Changing nozzles tends to be when I get clogs.

From your red pics I suspect that your Z is a tiny bit too low.

Also make sure you are using 7x7 bed leveling. The number of points is set in firmware or slicer.

In G-code the line:

G80

By itself will use whatever is set in firmware. The Line:

G80 N7

will force it to 7x7. Or set it in the LCD Menu: Settings-> Mesh Bed