Printing ABS "without" and enclosure?

Greetings!

I was wondering about the ABS printability on an open i3 MK3S "without" an enclosure.

I was planning to getting myself some eSUN ABS+ with it supposedly being less prone to warping but with it apparently not being particularly popular in my region makes getting my hands on it in either a timely or cost-effective manner pretty much a fools errand ( similar other ABS-S products aren't faring well either ) leaving me with only regular ABS for which I do not have a shroud for to prevent warping.

Though my i3 MK3S MMU2S is situated in a closable closet ( <- Click Link - Not perfectly airtight ) hence the "without" - How are my chances? None of the parts should exceed 120mm in either the X & Y Axis and less than 50mm in the Z.

Any opinions?

Draft shield

I don't have a Mk3 but I do print both ABS and ASA successfully without an enclosure. I get good results with a draft shield.

@durahl

As Towlerg mentioned you can get good results with a draft shield and no enclosure, but it really comes down to the shape and size of the part your going to print. The draft shield itself can warp and detach if your doing a large or tall print, becoming a detriment to the finished product.

The closet may help a lot more then you think, I didn't look at the image you posted of the closet, but as long as you can get the closet temp stable at around 37C to 40C'ish and you can eliminate the potential for temperature changing drafts across the print you have a very good chance of success. If you plan on open and closing the closet door because you are interested in your print you will be causing the very thing you would most want to avoid, drafts and rapid changes in temperature.

Something else I'd like to mention, filaments that make claims of warping less in my experience are basically a sales technique designed to get you to buy, ABS warps, and shrinks. it can be negated by proper procedure & technique, enclosures can be crucial to success. I personally don't look at eSUN as anything special <--keep this in mind.

If you think your not going to be able to help yourself and your going to keep looking in the closet because your interested in how the print is doing, I have a few suggestions.

Put the printer in a temporary enclosure, some might suggest a cardboard box, this has the potential to work fine, keep in mind that air tight isn't as important and temperature stability, and maintaining the proper temperature.

A printer in an air tight enclosure will heat the enclosure beyond acceptable levels rapidly and aside from filament cooling issues with the print, it will cause problems with the printer e.g. heat creep and deformation of the printer parts themselves.

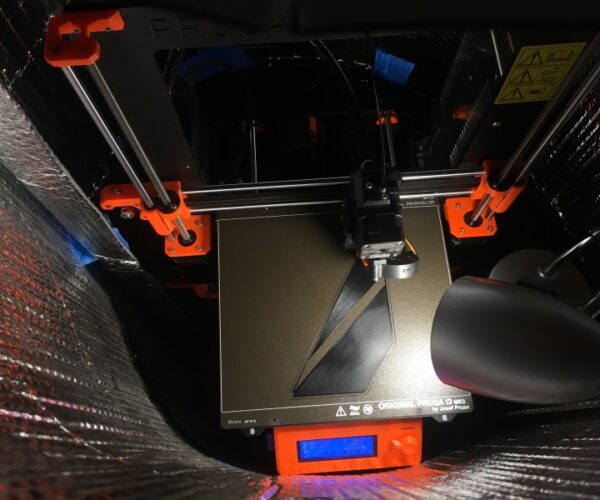

I'm not a big fan of the cardboard box, and I have found that "Mylar bubble wrap insulation" can be cost effective and do the job.

In many places this can be found at the local hardware store, or ordered online.

This is an image of a temporary enclosure I used when I had a need to print ABS on the Printer I keep in the living room.

I have two other Prusa's that are in enclosures, this one I normally use for fun and helping on the forums.

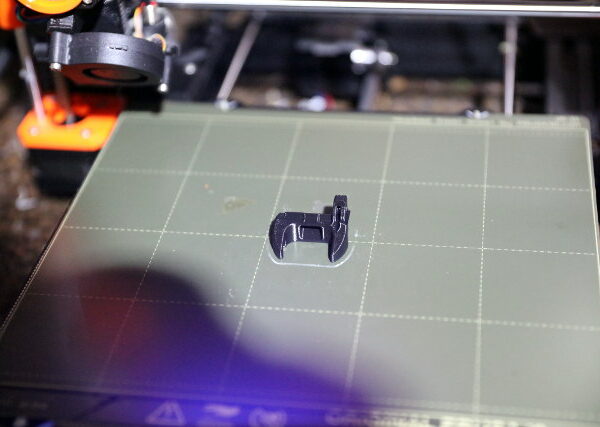

A look inside,

I use the cardboard placed on the top to control the temperature in the enclosure and it allows me to take a peek inside to check progress.

Hope this information is helpful

Good Luck

Swiss_Cheese

The Filament Whisperer

Worth a try

Mhh... Looks like it would be worth a try, thanks to both of you for the input! =)

The extruder fan can only cool til you get 40 degrees , put a temp sensor in the box you make and watch the temp, if it gets to hot open it a little.

Its working, kinda ;D

Thought about reporting in my findings with printing "Generic" ABS without an enclosure but in my closet... The prints come out without issues for as long as I'm not exceeding a roughly 150mm diameter area around the center of the build platform. Anything touching outside that area tends to lay down fine but then get peeled up with more layers added producing a poor finish.

The prints come out without issues for as long as I'm not exceeding a roughly 150mm diameter area around the center of the build platform. Anything touching outside that area tends to lay down fine but then get peeled up with more layers added producing a poor finish.

Something I already experienced with printing PLA / PETG but unlike with ABS it would usually only affect the absolute corner areas of the print bed outside of something like a 220mm diameter. Ah well... Means I cannot pack the bed like crazy and will have to do a bunch more extra prints ( including reprints of the unsatisfying warpsies ).

Oh yea... And the top layer surface finish looks like hot garbage compared to using Prusament PLA / PETG - At least sanding / filing it is a thing. Maybe I should have given CNC'ing the parts out of Delrin a try - Supposedly having the same heat resistance than what ABS has 🤔

I do some ABS all without enclosure, mostly small stuff and never had problems.

warping

I do some ABS all without enclosure, mostly small stuff and never had problems.

Small is fine. Size increases warping.

--------------------

Chuck H

3D Printer Review Blog

That's odd...

Still printing the parts in ABS when I just came across an odd situation...

Out of the previous batch of parts I had two failed copies ( of a total of four ) that peeled themselves up, so I quickly sent another file to the i3 MK3S with just those two failed copies. Keeping an eye on the start of it via the Camera I installed to keep the Closet closed I witnessed the Printer basically printing in thin air with the filament BARELY touching the print bed creating what looked something a Gen 0 Mendel 3D Printer would have produced and thus necessitating a recalibration of the First Layer and changing it from the previous 0.950 to something like 1.350... Uhh... Wha happun? 🤔

Should I expect the 3D Printer to suddenly revert back to the 0.950 values and then digging into the print bed?

@durahl

I'd check the PINDA probe clamp and make sure it didn't come loose because of the elevated ambient temps for starters. you should see some expansion of the machine but it should overall be fairly uniform. I know there have been some reports of the PINDA clamp needing a redesign for working in a heated environment and there are several designs available if that is the problem. I did not experience this on my MK3s.

Regards

Swiss_Cheese

The Filament Whisperer

Edit time ran out

Also you will notice if your still using your factory PETG fan shroud it will start to deform. this mostly happens because of the high bed temps and slow or no fan speeds, I printed my fan shroud out of ABS and I Keep the fan on very low when I don't really need it for the print to stop the fan shroud warping, some folks have printed theirs out of PC Blend for even higher heat resistance.

The Filament Whisperer

Deformation

I have replaced many of the heat-sensitive parts with either ASA or PC BLend because of the deformation.

--------------------

Chuck H

3D Printer Review Blog

I was told (by whom? probably here) that the factory fan shroud for my MK3S was supposed to be ABS.

It did, however, start drooping during a fairly long run of ABS prints.

I printed a remixed one out of PC Blend and it has not drooped yet. It was also a good excuse to order and play with the PC Blend.

Fan shrouds

The material your Prusa-made fan shroud is made of depends on which one and when you purchased them. They have been printed primarily out of PETG and ASA.

--------------------

Chuck H

3D Printer Review Blog