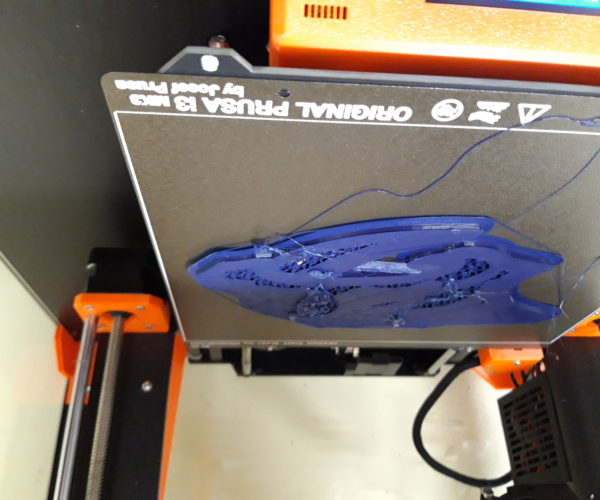

Print failure

Hi all,

I'm new here in this community.

Unfortunately I'm struggling with my MK3S already several times with large flat prints that they lift edges and start do tetach from the printbed during printing(see picture).

I have following environement.

Printing PLA with recomendet temperatures, tried both print plates, PEI and powder coated, have the V2 enclosure with one door 45deg open, all that is located in the basement of my home with about 12-14°C (i guess this could be the problem)?

Do you eperts have any recomondations how to success wirh these temperatures around my printer/enclosure?

Mamy tha ks for your support

RE: Print failure

Well... you're printing on the ceiling! (The forum software isn't great at dealing with pics).

I'm going to give you a dump of info on the most common failures. Try these out, then report back if you have continued issues...

-

A dirty PEI print surface. Even if you don't think this is the cause, it's always a good idea to make sure your PEI surface is clean before trying any other fixes. If it's a smooth PEI sheet, take it to the kitchen sink and give it a good dunk with Dawn (original formula, no vinegar or hand softener variants) dishwashing soap or your local equivalent (e.g. Fairy in UK). Use a clean paper towel to clean it off, and another to dry it. Avoid using any sponge or cloth that has been in contact with grease. Above all else, avoid touching the PEI print surface. Once it's good and clean, you should be able to use 91%+ isopropyl alcohol between prints, 100% acetone when that fails , and another dunk when acetone fails. Worst-case, use a 3M 7445 ScotchBrite pad or equivalent on smooth PEI to give it a very light buff, but only infrequently. If you've got a textured powder-coated PEI print surface, the official instructions are to use 91%+ isopropyl alcohol on it only. Rumors persist that some tribes deep in the jungle have had good luck getting started with these sheets by giving them a wipe with 100% acetone and a dunk with Dawn. Either way, there's no real warranty on these sheets. YMMV.

-

If you have not already done so, try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the on-board routine. It's much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers.

RE: Print failure

Many thanks for that extensive support.

Did alot of dishwashing on the pei sheet weeks ago, then switched to the textured sheet, but it seems to be a bit tricky with pla.

Havend done isoprop cleaning on the pei sheet so far, but will try as well. Further will try the 75by75 live adjust tomorrow, sounds more effective to me.

The above shown print i will retry next weekend and will let you know about the results.

You think that all has nothing todo with the low temperature in the room?

Thanks

RE: Print failure

Detergent and water scrubbing is at least ten times more important on the textured sheet than on the smooth (they are both PEI).

RE: Print failure

@robert-rmm200

I do a isopropyl (90%) wipe on my PEI sheet before every print. It works great. Occasionally I wash the sheet with dishwashing soap and hot water (mainly when I'm switching filament types or if I start seeing adhesion issues). If adhesion is degraded even with this treatment, then an acetone wipe refreshes the sheet, but should not be done too often since, as i understand it, it actually removes a bit of PEI.

RE: Print failure

@robert-rmm200

I do a isopropyl (90%) wipe on my PEI sheet before every print. It works great. Occasionally I wash the sheet with dishwashing soap and hot water (mainly when I'm switching filament types or if I start seeing adhesion issues). If adhesion is degraded even with this treatment, then an acetone wipe refreshes the sheet, but should not be done too often since, as i understand it, it actually removes a bit of PEI.

No argument here. That is the procedure I recommend. My comment was to the OP, who never indicated he used detergent and water on the textured plate.

RE: Print failure

hi,

thanks for the helpful advises.

on the textured pei sheet I did only isopropyl cleaning, I recall having read this somewhere. It seems I have to do the dishwasher cleaining there as well.

right now I did the dishwasher clean and afterwards isopropyl wipe for a simple print on the smooth sheet. just to see how it sticks. It looks like I was just to sloppy with the cleaning of the sheets. looking forward to try the large print again soon.

RE: Print failure

There is cleaning and there is cleaning... Don't use the dishwasher... Soap is too caustic.

I was referring to hand cleaning with an unscented detergent like Dawn. Scrub vigorously with your hands and rinse thoroughly.

RE: Print failure

Thanks, with ddishwasher cleaning and a iso wipe it went well on the smooth pei sheet.

Do you think such a pla print should be possible on the textured sheet as well?

RE: Print failure

After resolving my adhesion problems, the sheet I choose is based on the surface finish I want. Which is how it should be.